Slow releasing device for volatile medicine and air conditioner using same

A slow-release device, volatile technology, applied in the direction of trapping or killing insects, air conditioning systems, distribution devices, etc., can solve the problem of inability to respond to changes in external humidity, inability to uniformly volatilize or release drugs, and reduce the response of the release amount. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

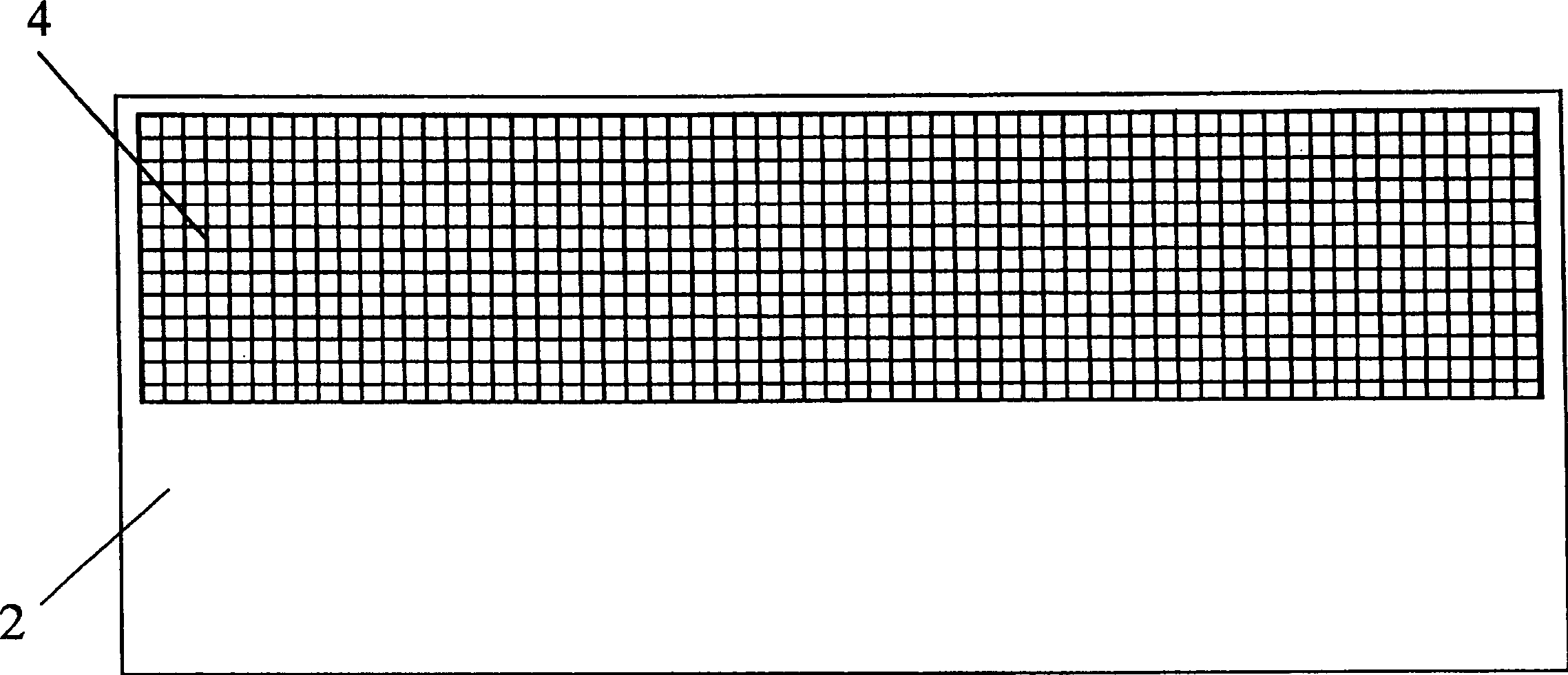

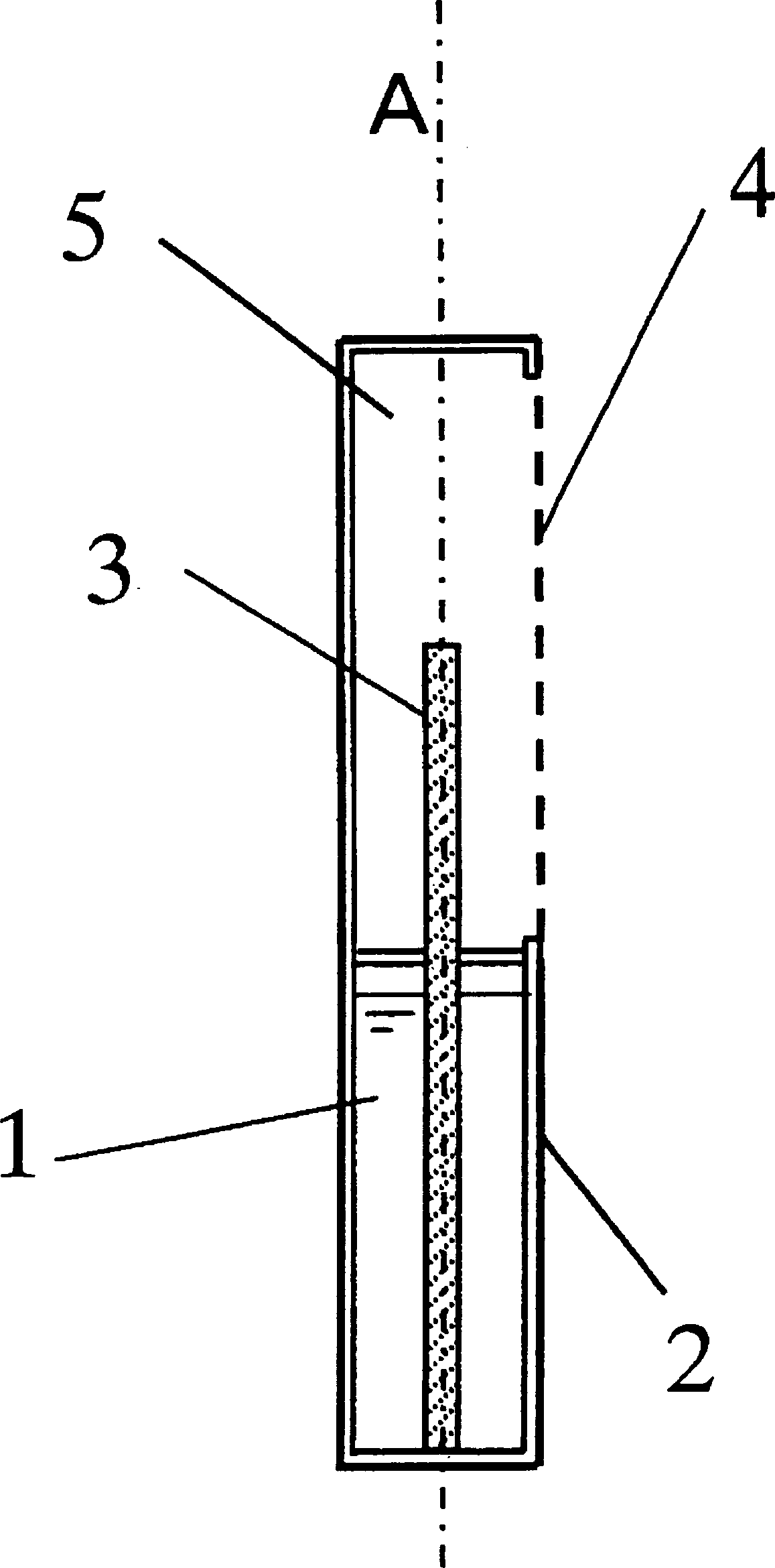

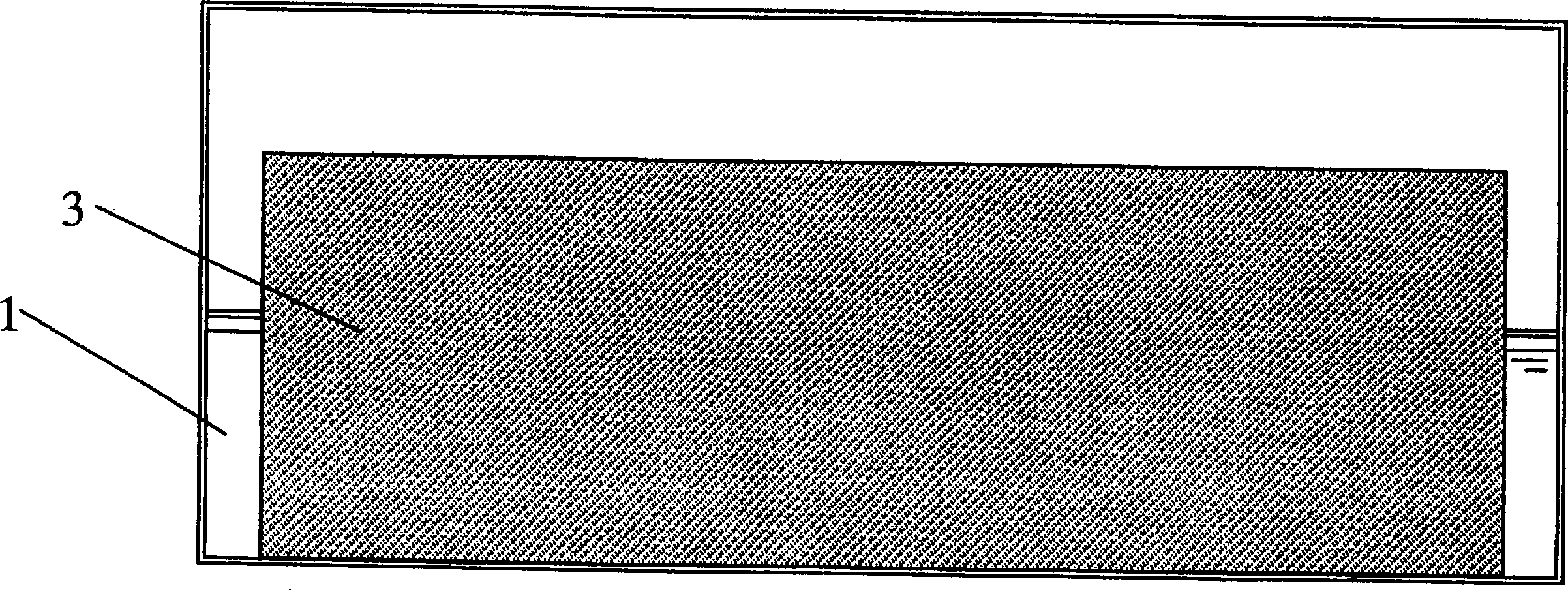

[0033] figure 1 It is a front view showing the appearance of the volatile drug sustained release device of this embodiment, figure 2 It is a side sectional view of the volatile drug sustained release device, and is a front sectional view of the volatile drug sustained release device along the A direction. 1 is the drug allyl isothiocyanate, 2 is the colorless and transparent container made of polyethylene terephthalate (PET) used to fill the drug, and 3 is the absorption of isothiocyanate due to the use of capillary phenomenon A polypropylene non-woven sheet of allyl acrylate having an apparent density of 0.8 g / ml and allowing the ends of the sheet to reach the bottom of the container 2 . 4 is a temperature-sensitive film after laminating viscose processed paper on polyethylene, using a 5g / m2 viscose / pulp non-woven fabric on an 80μm polyethylene sheet 2 The structure after applying a certain amount of glue, 5 is a space part formed by the polypropylene non-woven fabric shee...

Embodiment 2

[0036] Figure 5 To show the front view of the appearance of the volatile sustained-release device of this embodiment, Figure 6 It is a side sectional view of the volatile sustained release device. 18 is allyl isothiocyanate, 19 is a colorless and transparent polyethylene terephthalate (PET) material container used for filling medicine, and 20 is used to absorb isothiocyanate by capillary phenomenon The polypropylene foam with continuous foaming function of allyl ester has an apparent density of 0.8g / ml, and 21 is a temperature-sensitive film after laminating viscose processed paper on polyethylene, which has the same structure as in Example 1, 22 is a container for supporting the welded humidity-sensitive film 21 and forming a space 23, wherein the space 23 is filled with volatilized allyl isothiocyanate. The container 19 and the container 22 are separable, and the container 19 is pressed into the container 22 for fitting, and the container 19 and the container 22 are kept...

Embodiment 3

[0039] Figure 7 To show the front view of the appearance of the volatile sustained-release device of this embodiment, Figure 8 It is a side sectional view of the volatile sustained release device. 24 is allyl isothiocyanate, 25 is a colorless and transparent PET material container used for filling medicine, and 26 is a polypropylene foam with continuous bubble function that absorbs allyl isothiocyanate by capillary phenomenon. Bubble body, apparent density is 0.8g / ml, 27 is the temperature sensitive film after laminated viscose processing paper on polyethylene, and the structure is the same as embodiment 1, 28 is the humidity sensitive film 27 that supports melting at the same time A container for forming the space portion 29 . The container 25 and the container 28 are separable, and the container 25 and the container 28 are kept airtight by pressing the container 25 into the container 28 for fitting, and by externally connecting the inner peripheral contact portion of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com