Connector having dust proof cover

A dust-proof cover and connector technology, applied in the direction of the base/shell, etc., can solve the problems of not being completely dust-proof, increasing the cost, and inconsistent with the general specifications of the joint industry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

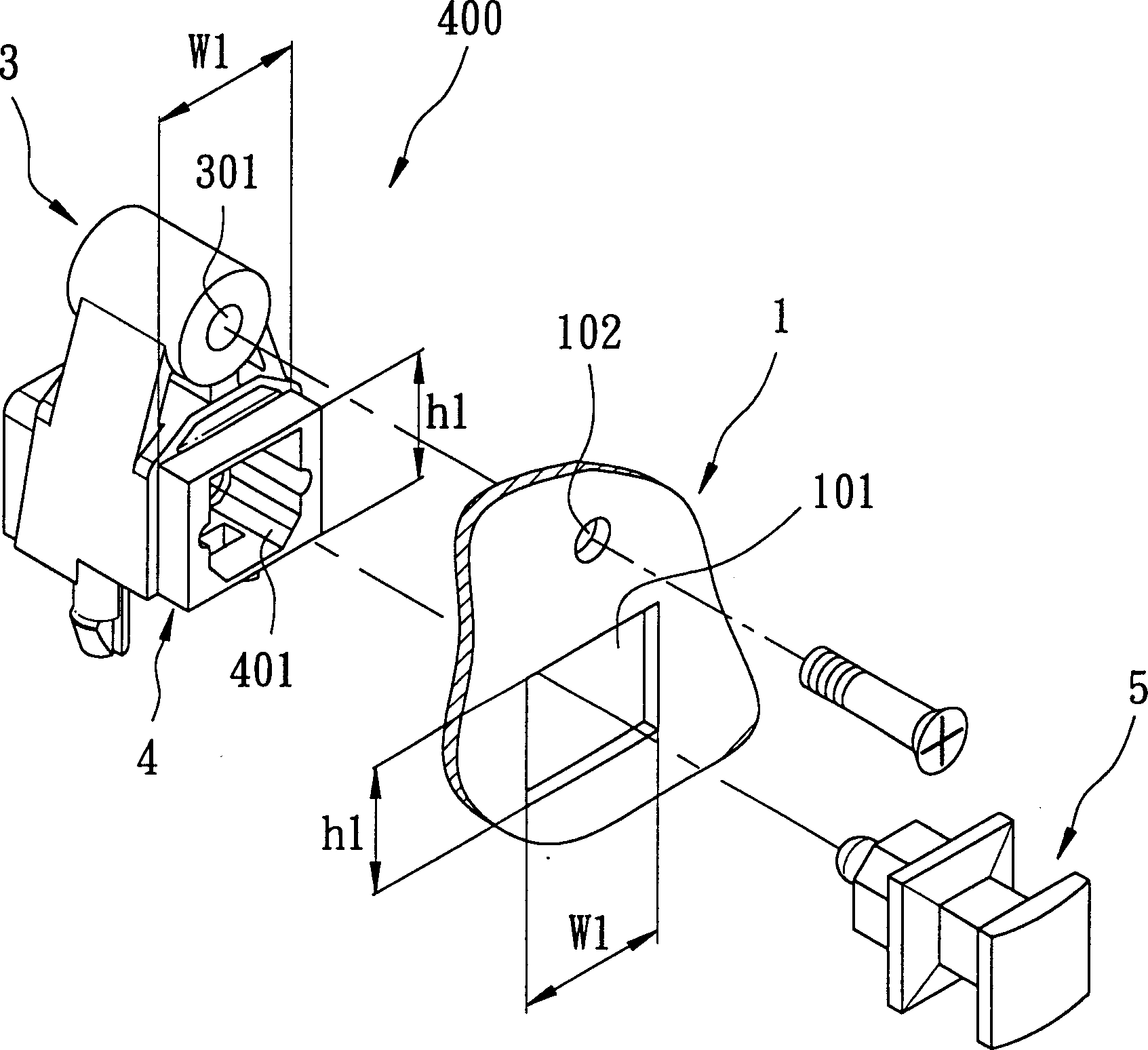

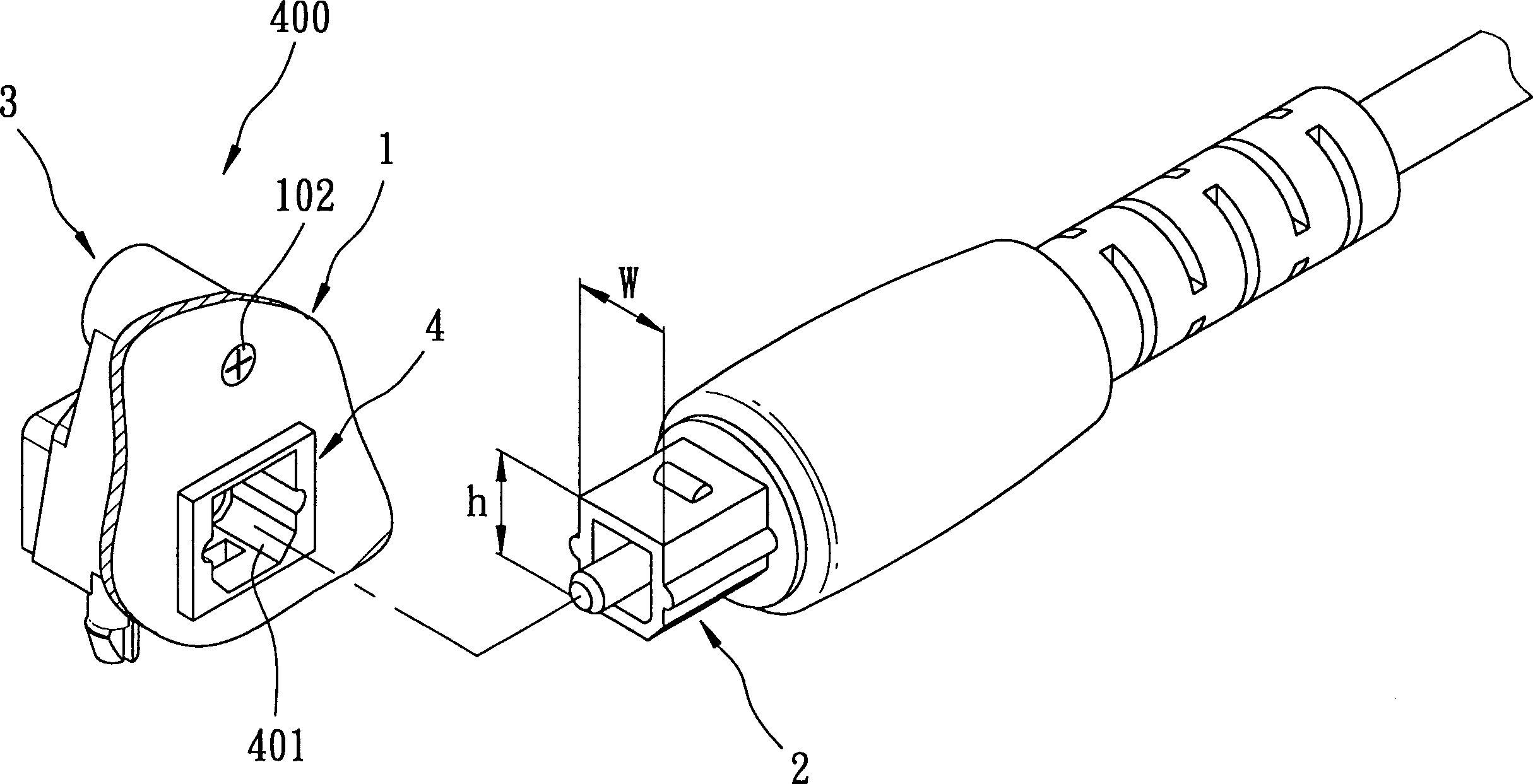

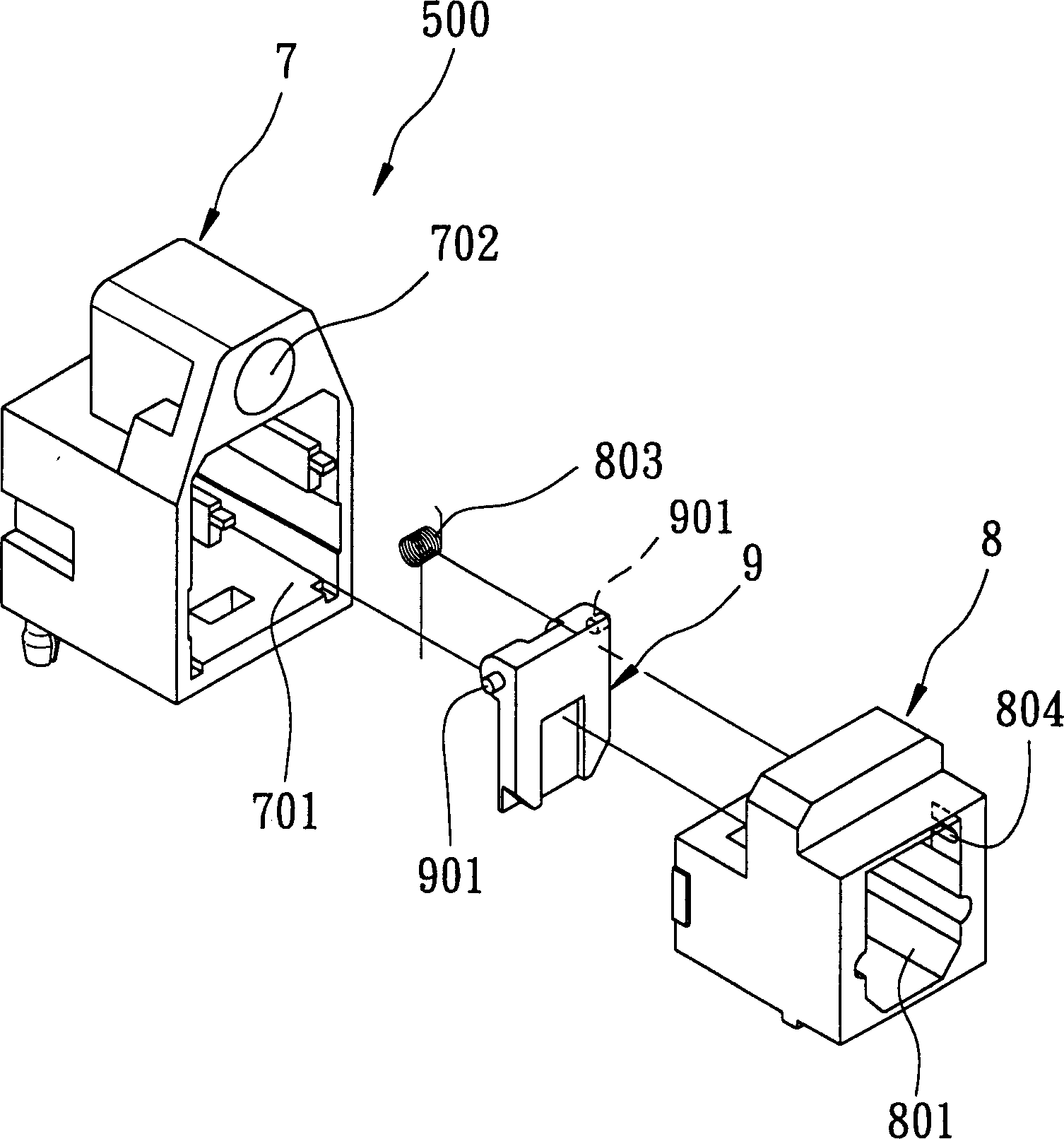

[0025] refer to Figure 6 , 8 , the connector 100 with dust cover of the present invention can be installed on a substrate 300 (the substrate 300 can be installed on a DVD player or a VCD player), and the connector 100 can be an optical fiber connection device for the insertion and positioning of the optical fiber cable terminal 2, the base plate 300 has a mounting hole 310, and a locking hole 320, the size of the optical fiber cable terminal 2 is a general standard established in the industry, the A preferred embodiment of the connector 100 includes: a housing 10 , a connector 20 , and a dust cover set 30 .

[0026] The casing 10 has a first accommodating space 11 with an opening facing forward, and a locking hole 12 .

[0027] The joint 20 is made of heat-resistant and wear-resistant high-hardness plastic material, and has a bottom wall 21, four side walls 22, 23, 24, 25 extending forward along the periphery of the bottom wall 21, and a The bottom wall 21 and the side wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com