Washing spray nozzle

A nozzle and washing liquid technology, applied in the direction of spraying device, spraying device, liquid spraying device, etc., can solve the problems of uneven washing liquid particles, pattern damage of precision parts, insufficient particle density, etc. , the effect of high washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] specific implementation

[0029] Next, embodiments of the present invention will be described with reference to the drawings, but the present invention is not limited thereto.

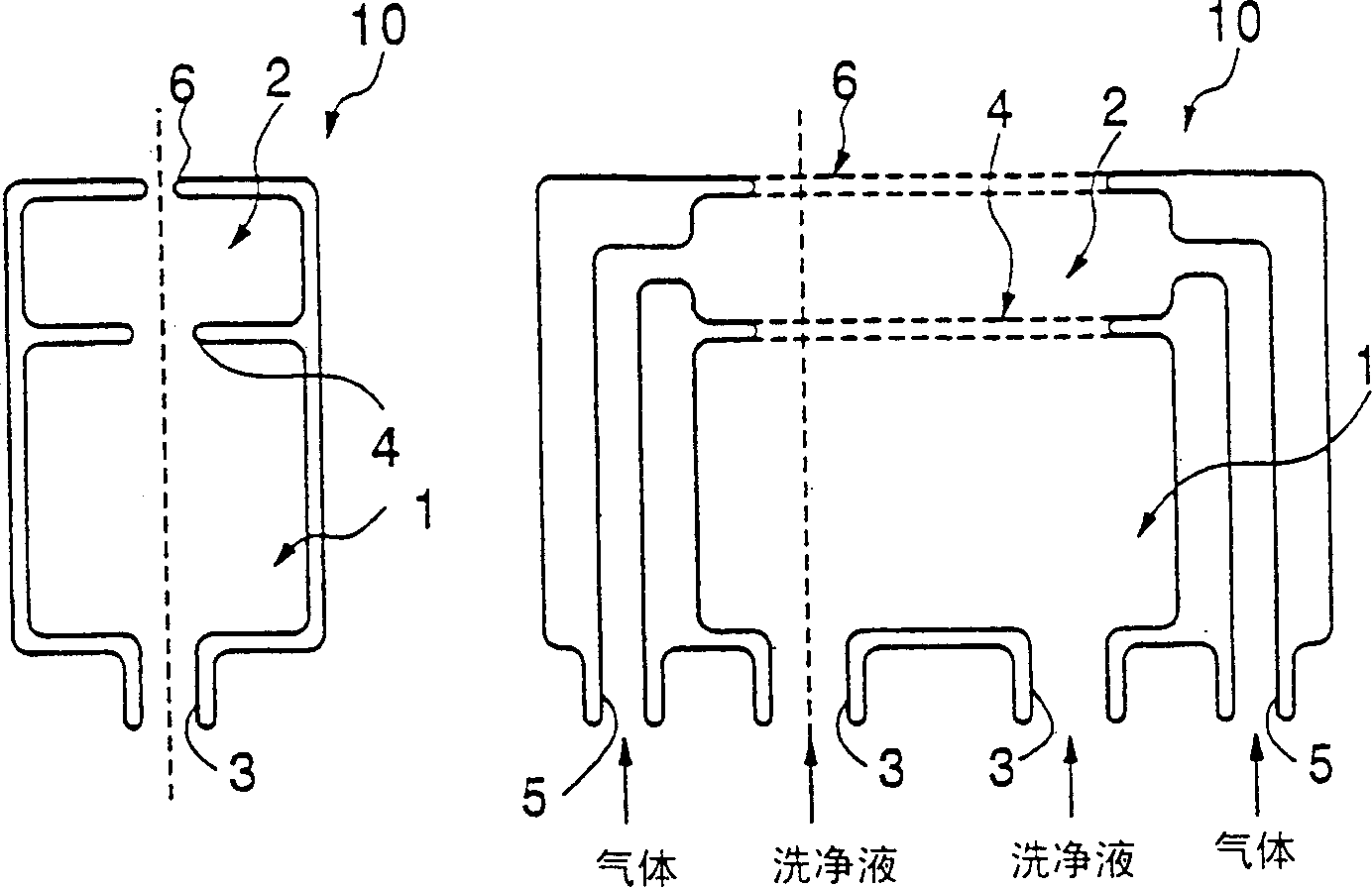

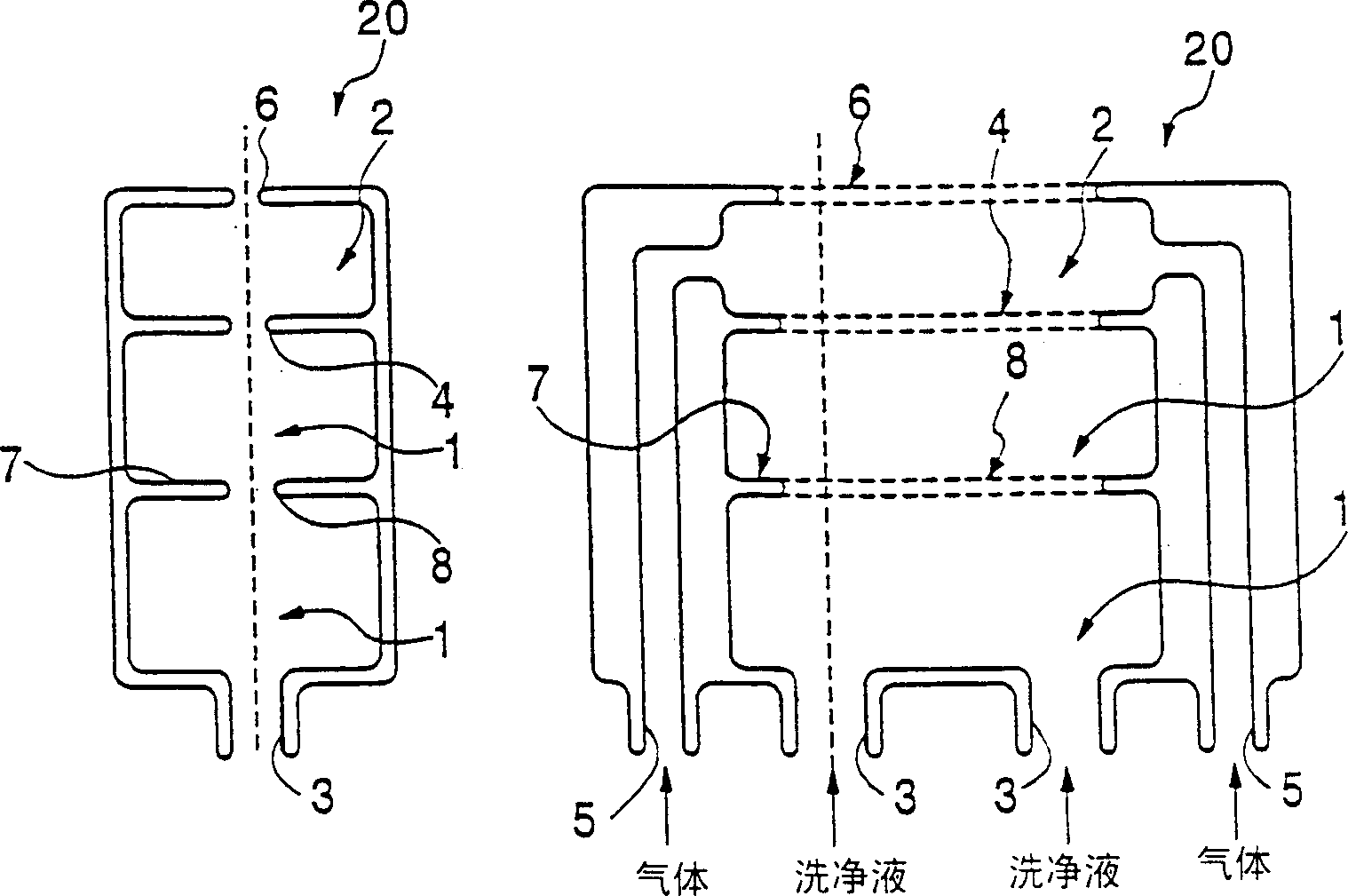

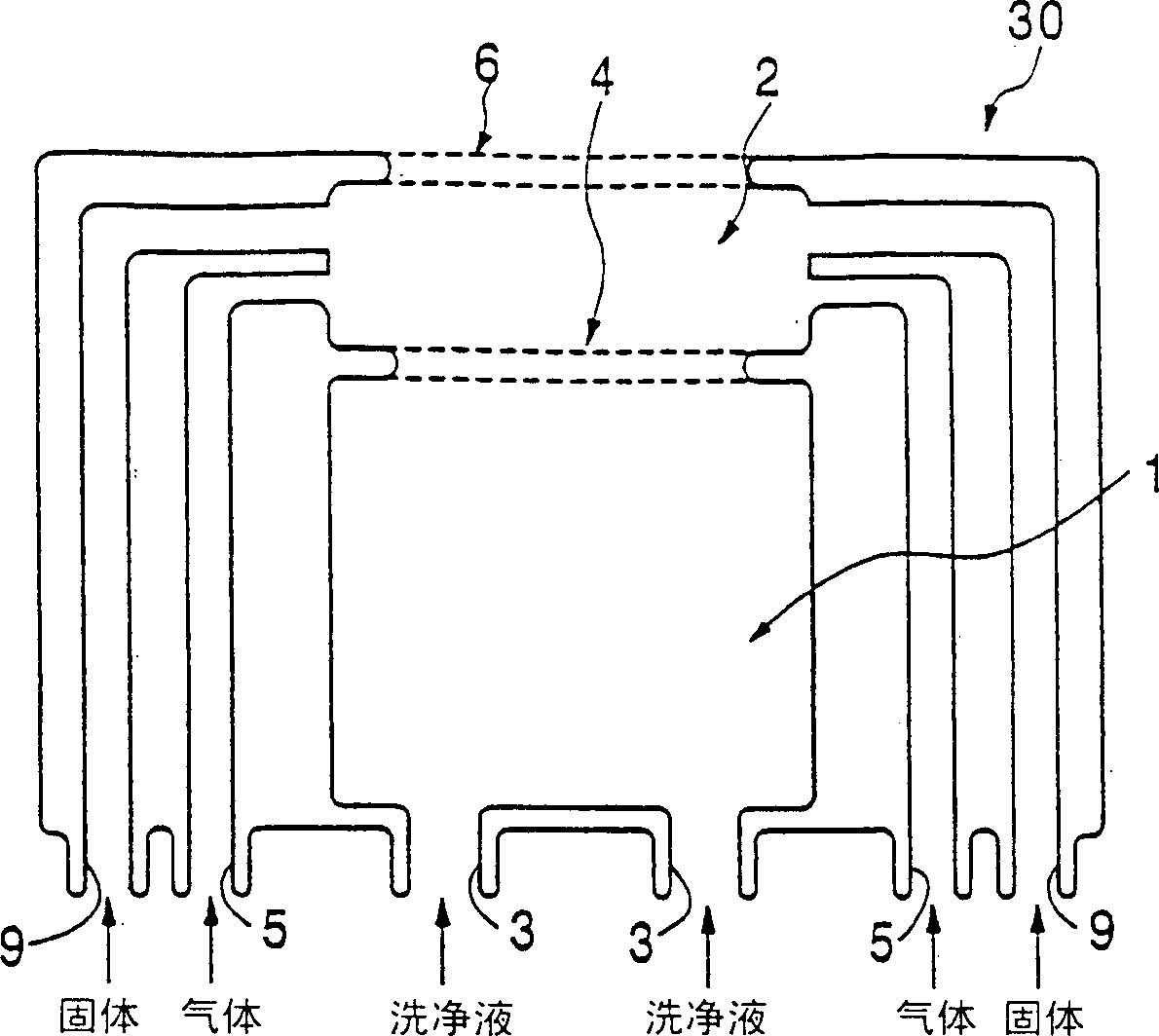

[0030] figure 1 It is explanatory drawing which shows one example of the washing nozzle of this invention. Inside the washing nozzle 10 of the present invention, there are two spaces in which the stirring chamber 1 and the mixing chamber 2 are provided. The stirring chamber 1 has a cleaning liquid supply port 3 and a slit-shaped liquid discharge port 4 . The mixing chamber 2 has a gas supply port 5 and a slit-shaped washing liquid discharge port 6 , and communicates with the stirring chamber 1 through the liquid discharge port 4 . Among the slit-shaped liquid discharge port 4 and the washer liquid discharge port 6 , the area of the washer liquid discharge port 6 is smaller than that of the liquid discharge port 4 . But sometimes the area of the washing liquid ejection port 6 is larger t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com