Stitch forming method and device

A technology of stitches and flat seams, which is applied in the field of stitch formation and devices, can solve the problems of low work efficiency, inability to form long stitches, and poor durability, and achieve the goals of improving sewing efficiency, good impact resistance, and improving product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

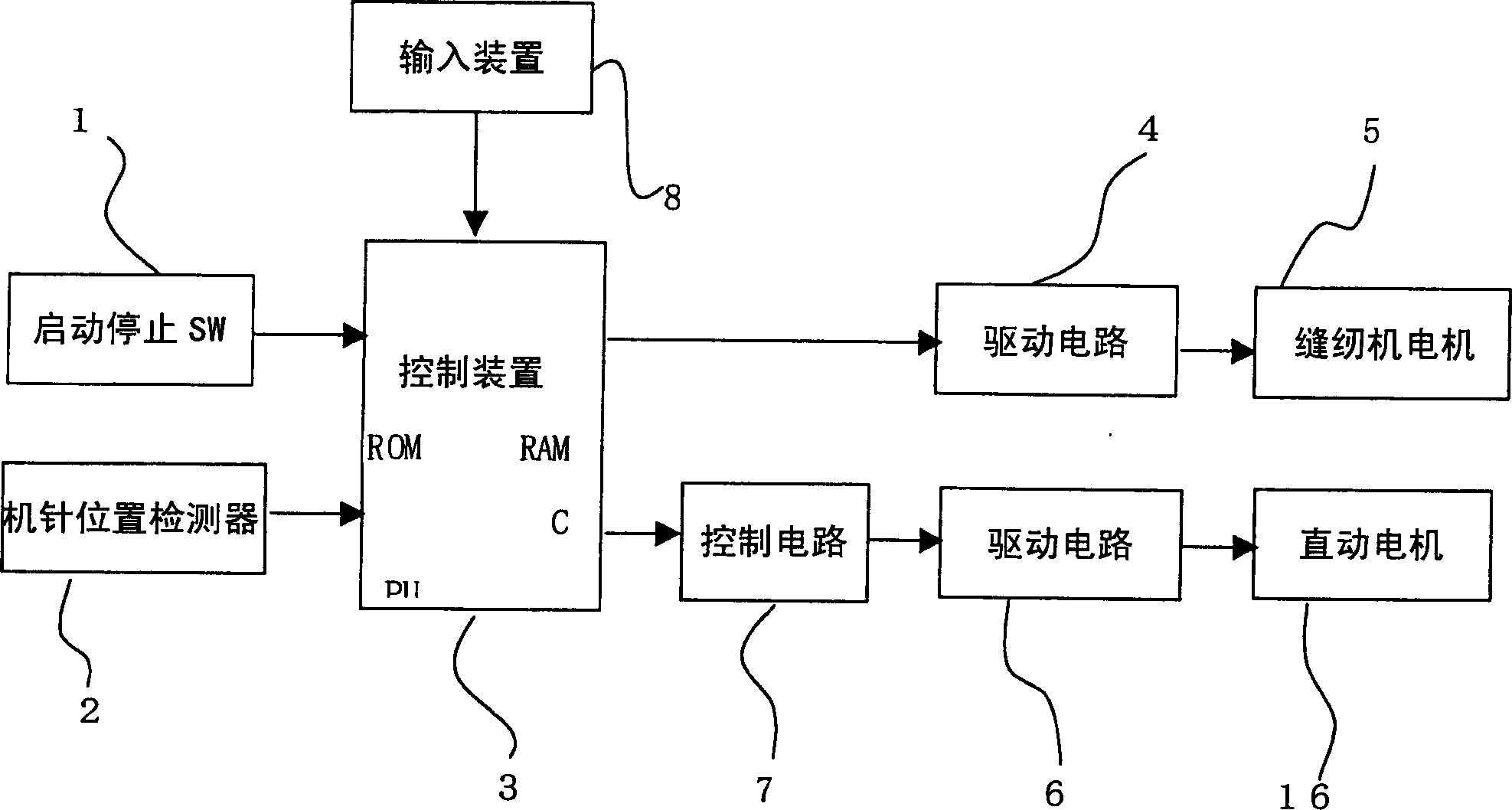

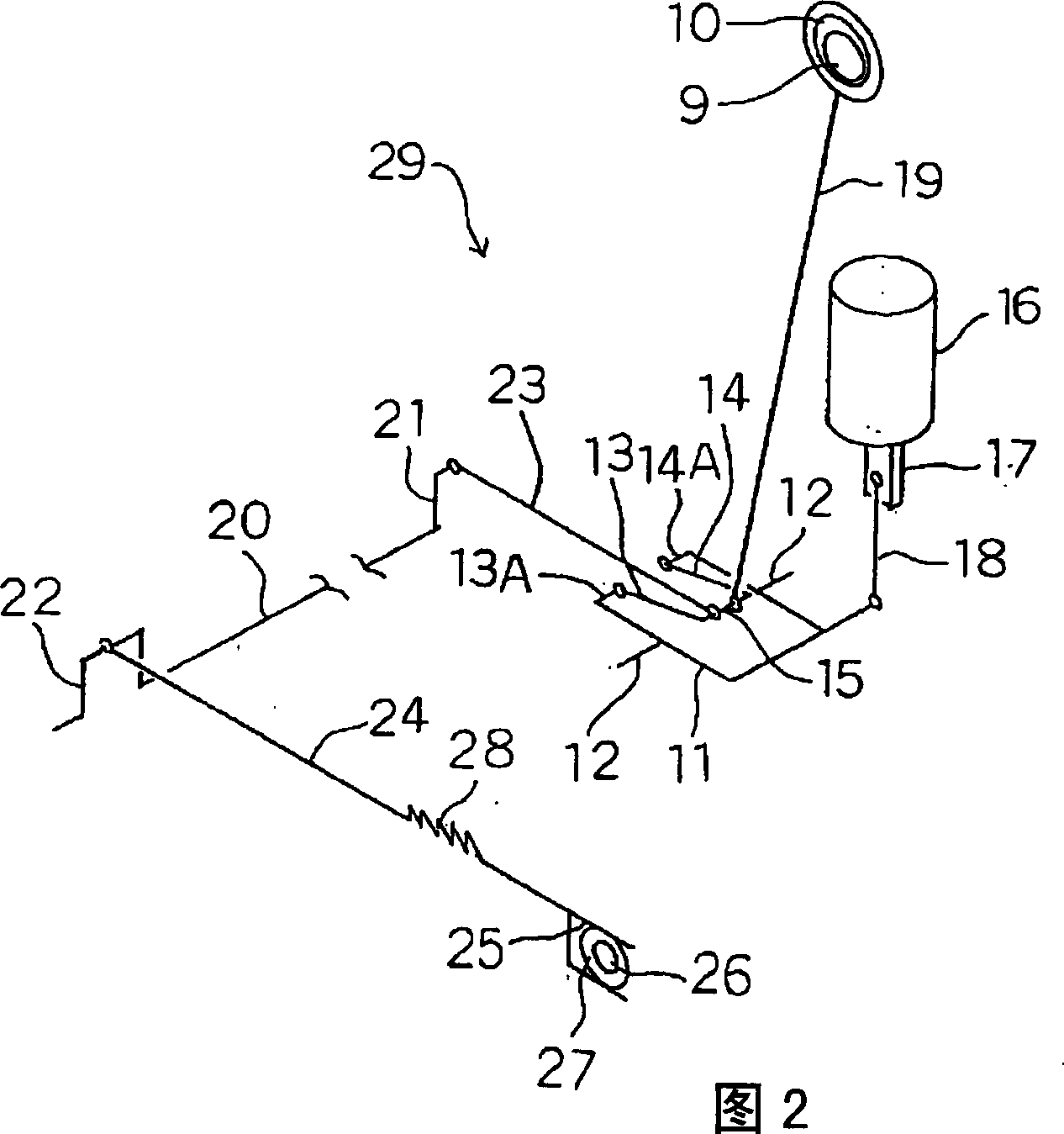

[0040] Below, combine Figure 1 to Figure 5 , Embodiment 1 of the present invention will be described.

[0041] The cloth feeding device 29 shown in FIG. 2 has the same structure as the cloth feeding mechanism of conventionally known sewing machines in principle. 9 is the main shaft of the sewing machine, and 10 is an eccentric cam arranged on the main shaft 9.

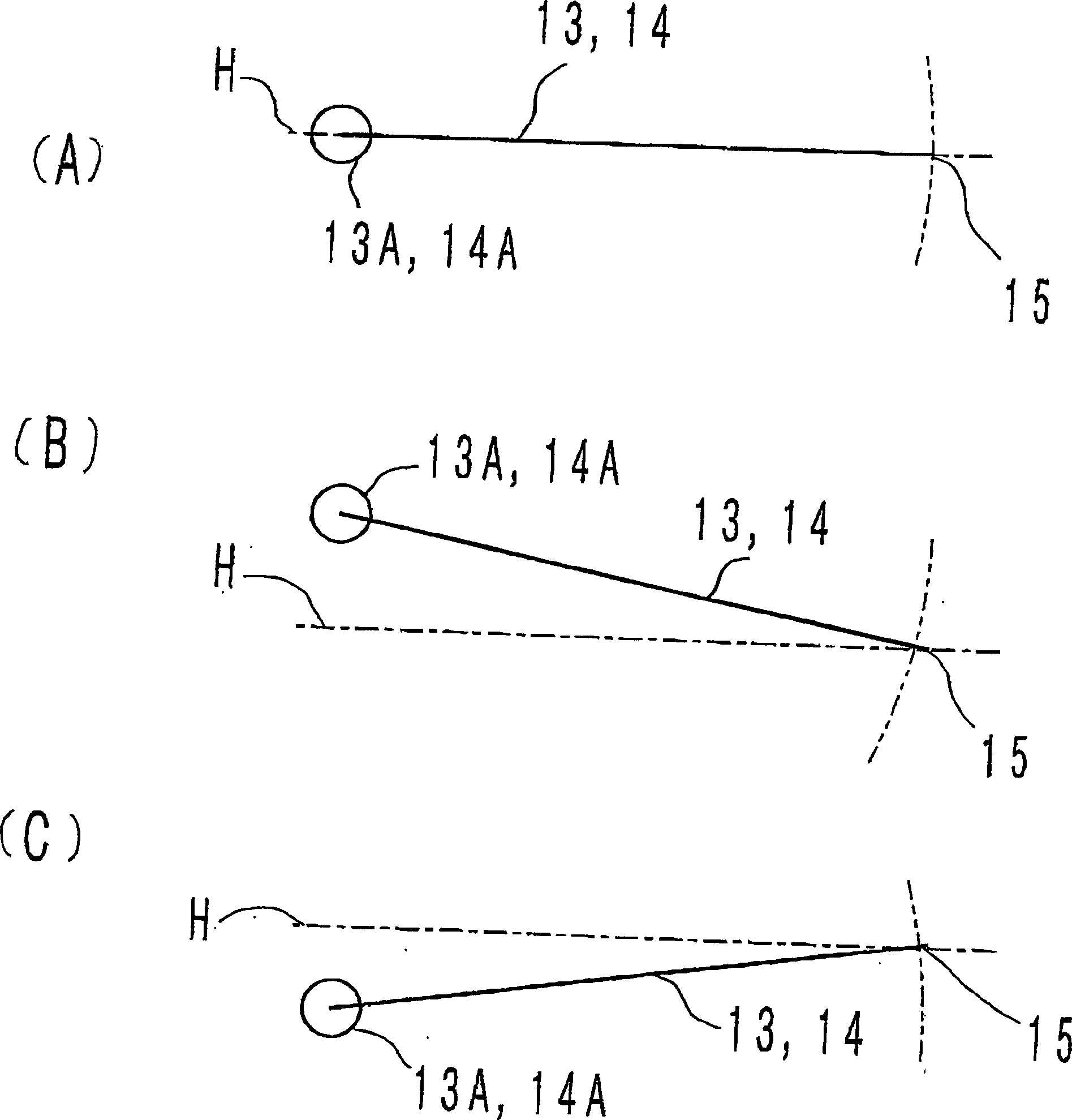

[0042] 11 is a feed amount changer, the central part of which is rotatably supported by a not-shown sewing machine bed via a shaft 12 . At the left end of the feed amount changer 11, the roots of the two connecting rods 13 and 14 of equal length are rotatably supported on the coaxial shafts 13A and 14A, and the front ends of the two connecting rods 13 and 14 are connected to a common on axis 15. The cloth feeding adjustment mechanism is composed of the cloth feeding amount converter 11, connecting rods 13, 14, shafts 12, 14, etc.

[0043] 16 is a direct drive motor fixed on the sewing machine frame not shown, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com