Backwater control system of water cut-off machine

A technology of water return control and water cutting machine, which is applied in the direction of manufacturing tools, used abrasive processing devices, abrasives, etc., and can solve problems such as leakage of high-pressure water switch valves, poor working performance and stability, and easy damage to valve core components. , to achieve the effect of solving the backwater problem, reducing the suction force and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

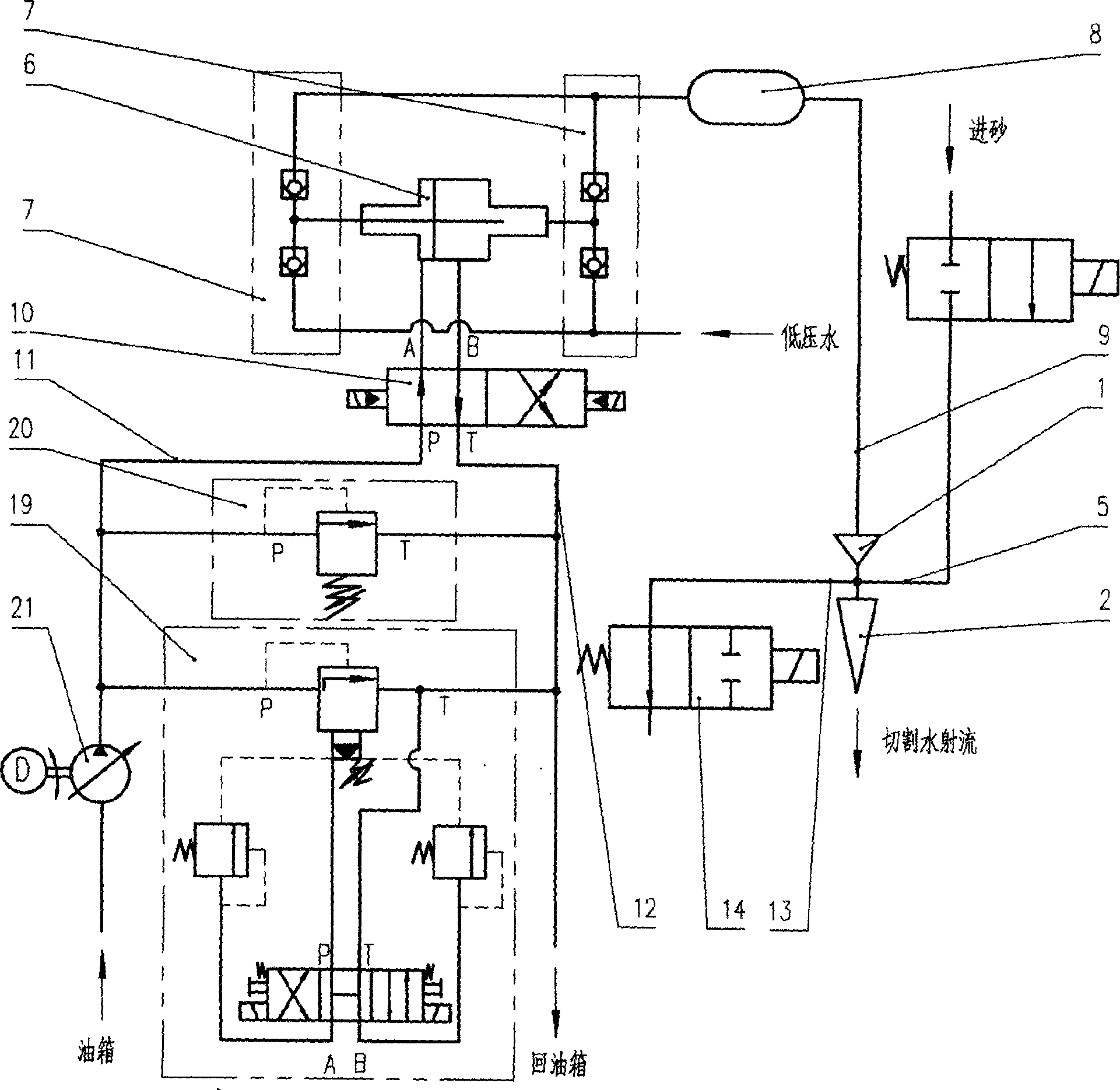

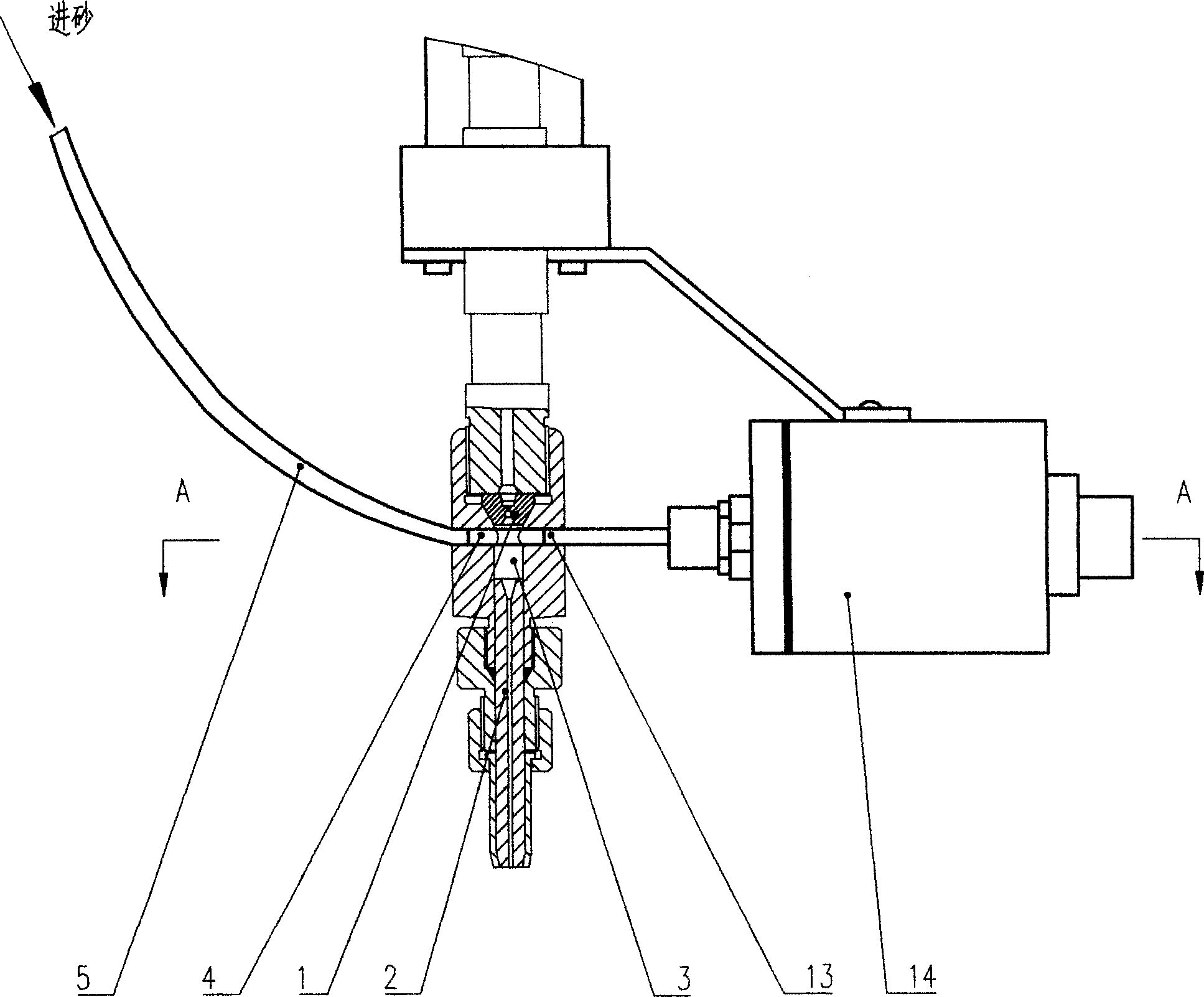

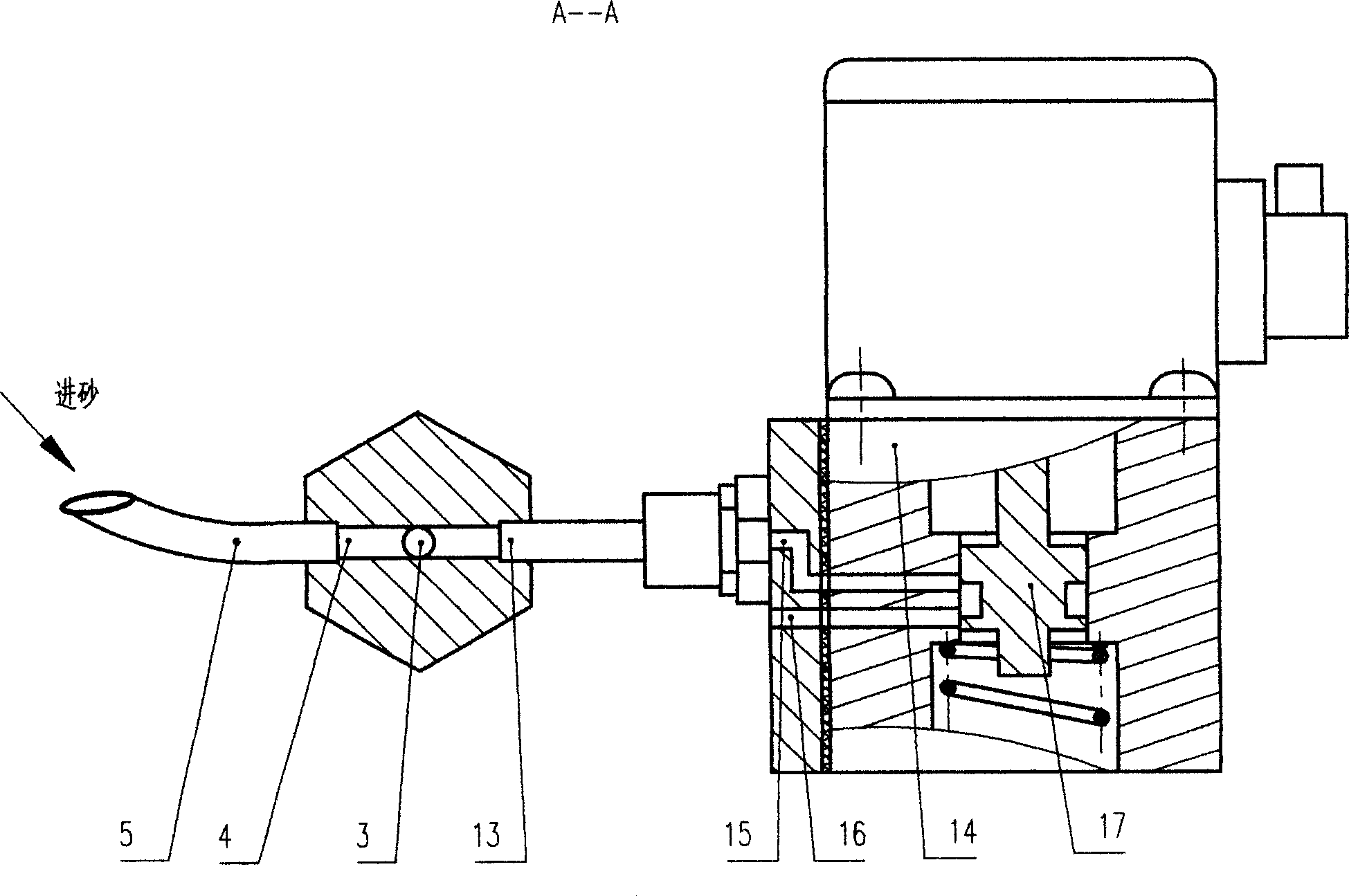

[0011] see also figure 1 , figure 2 and image 3 , the return water control system of the water cutting machine includes a water nozzle 1 and a sand nozzle 2 connected in series along the water flow direction, and a sand inlet 4 is opened in the mixing chamber 3 between the water nozzle 1 and the sand nozzle 2, and the sand inlet 4 is connected to Sand delivery pipe 5 is arranged. The water inlet of the water nozzle 1 is connected to an ultra-high pressure water generation system, which includes a supercharger 6, and the high-pressure water output port of the supercharger 6 is connected to a high-pressure water accumulator 8 through a combined check valve 7, and the high-pressure The water accumulator 8 is connected to the water nozzle 1 through the water delivery pipe 9, the two oil inlet and outlet ports of the supercharger cylinder are respectively connected to the execution output port of the reversing valve 10, and the high-pressure oil input port and the oil return po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com