Process and device for making air metal intlet of fan

A processing technology and air inlet technology, applied in the field of fan metal air inlet processing technology and its equipment, can solve the problems of cumbersome procedures, poor quality of parts, etc., and achieve the effects of improving work efficiency, convenient operation and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

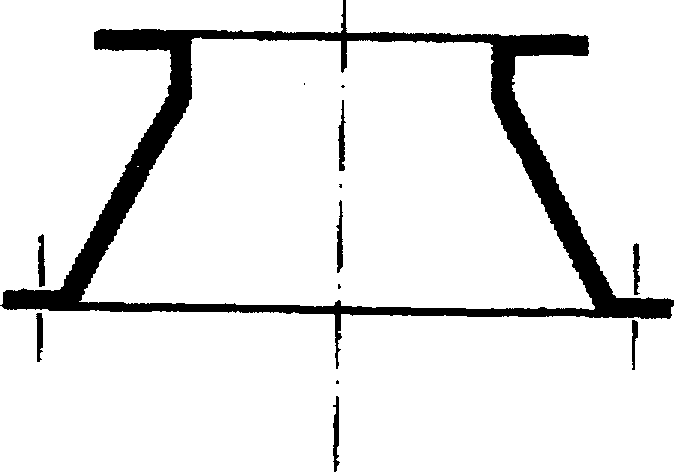

[0027] Such as Figure 6 , which is the shape structure of the metal air inlet of the fan.

[0028] The processing technology is:

[0029] 1. Unloading, according to the size of the air inlet, a circular material plate is unloaded;

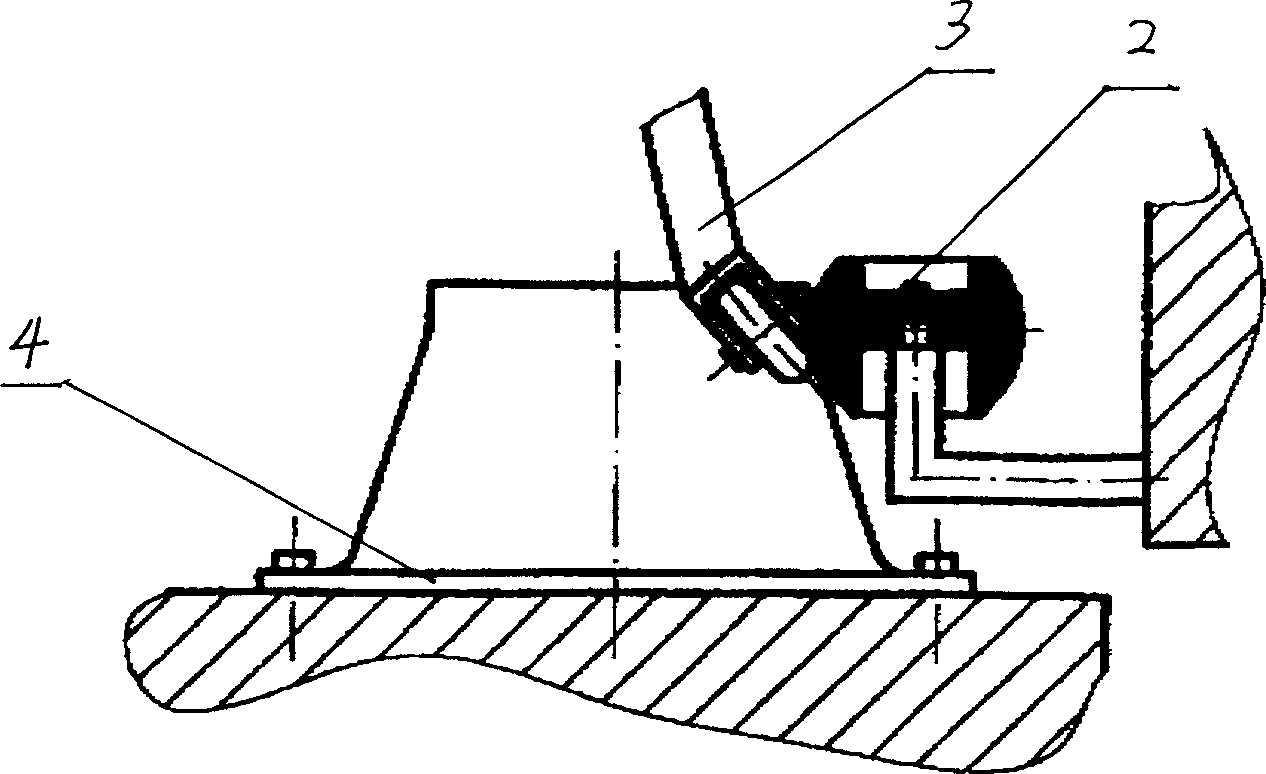

[0030] 2. Fix the material plate on the bottom surface of the fixed mold, drive the fixed mold and the material plate to rotate on the fixed mold fixing lathe, and use the spinning wheel 3 to spin the material plate into a cone-shaped workpiece;

[0031] 3. Unload the cone-shaped workpiece from the fixed mold, install it on the bottom plate 4, and anneal the cylindrical part of the upper mouth;

[0032] 4. If image 3 , put the cylindrical part of the cone-shaped upper mouth against the movable mold 2, and also use the spinning wheel 3 to flang the part;

[0033] 5. After the flanging is completed, the edge trimming is carried out, the movable mold leaves the workpiece, and the unloaded workpiece is the air inlet.

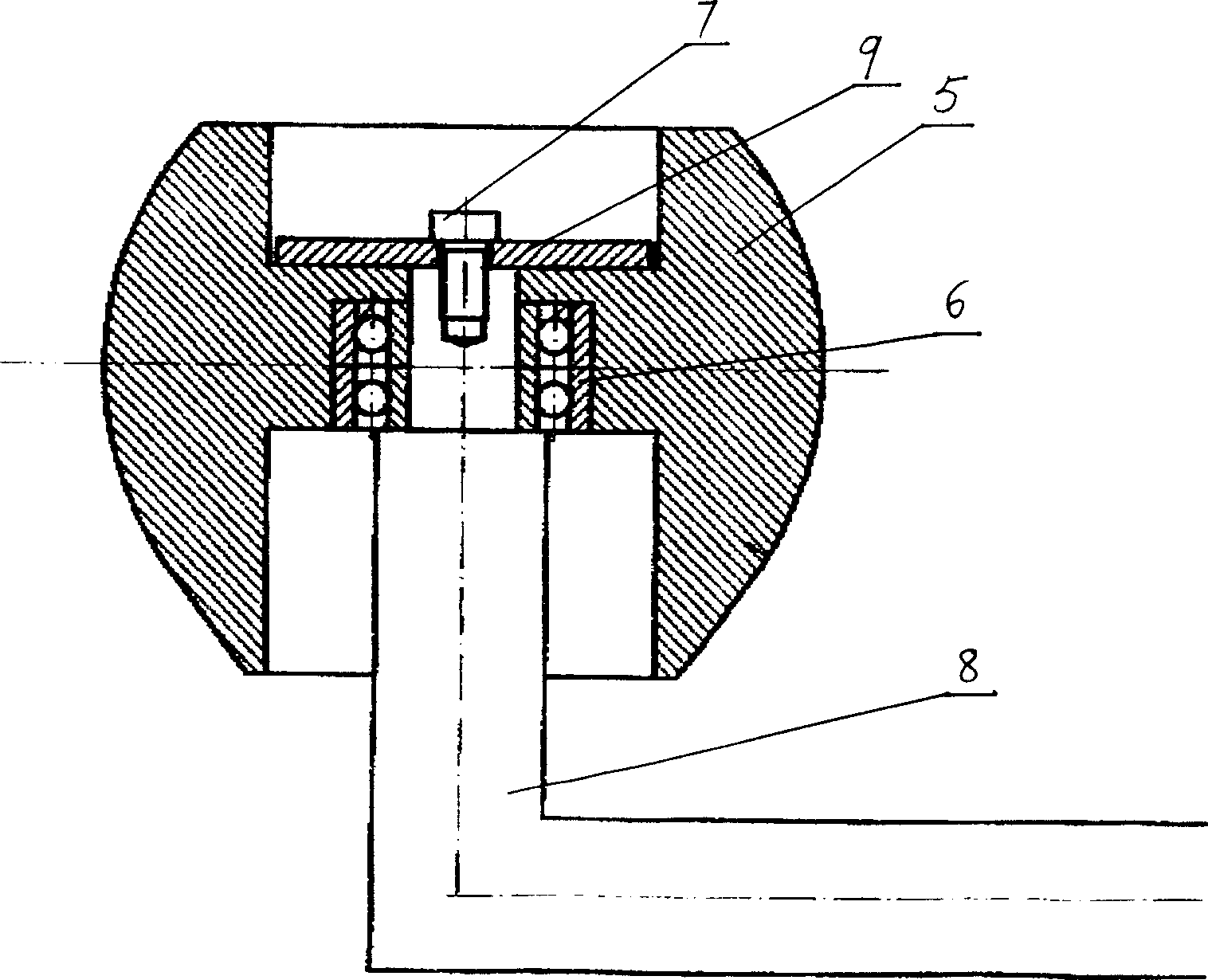

[0034] The shape of the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com