Method and special apparatus for three-D micro image forming of metal surface scatch

A three-dimensional imaging, metal surface technology, applied in the direction of testing material hardness, optical testing flaws/defects, etc., can solve the problems of inaccurate metal scratches, convenient detection and recording, etc., to achieve the effect of fast shooting and safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

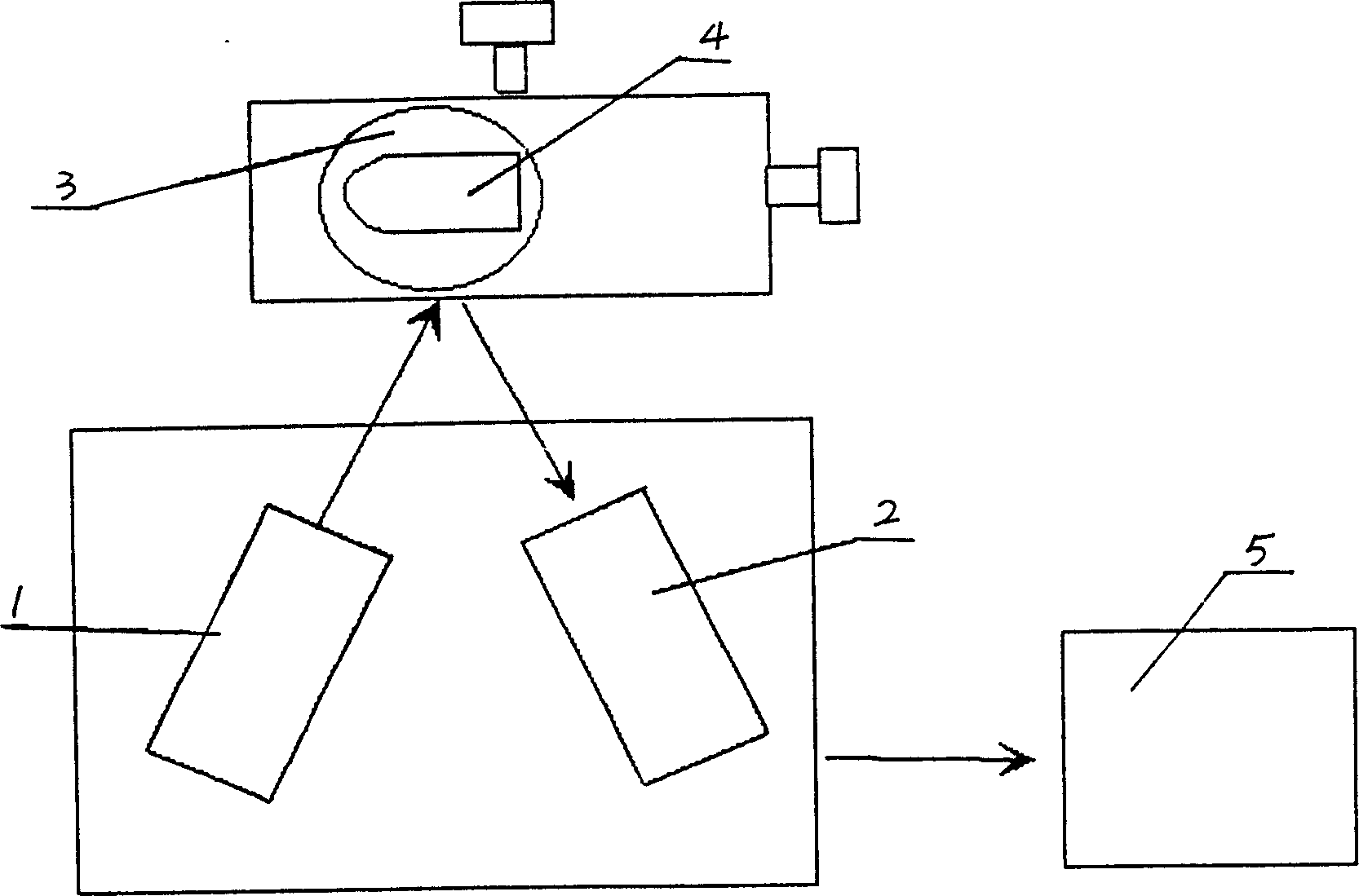

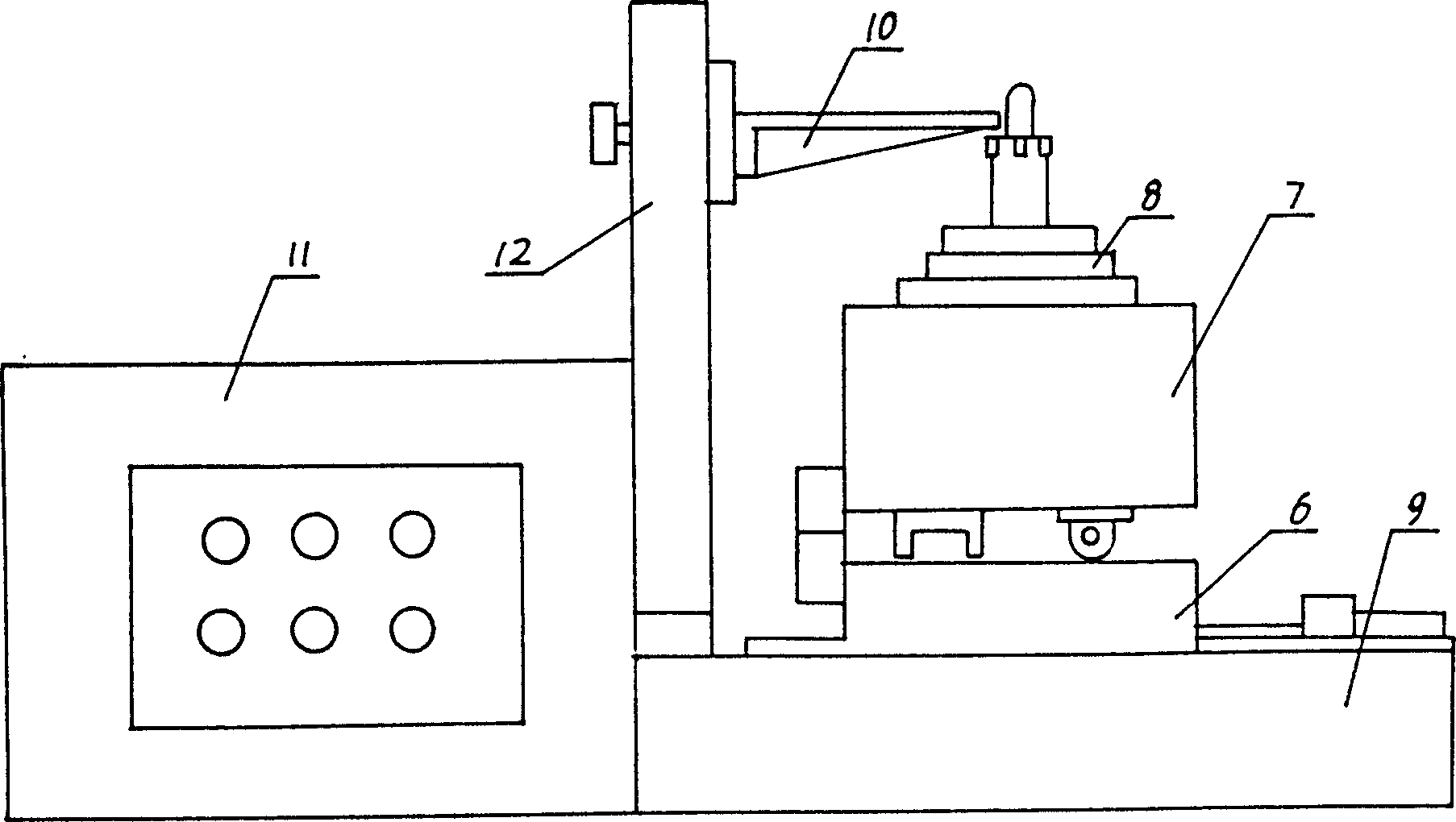

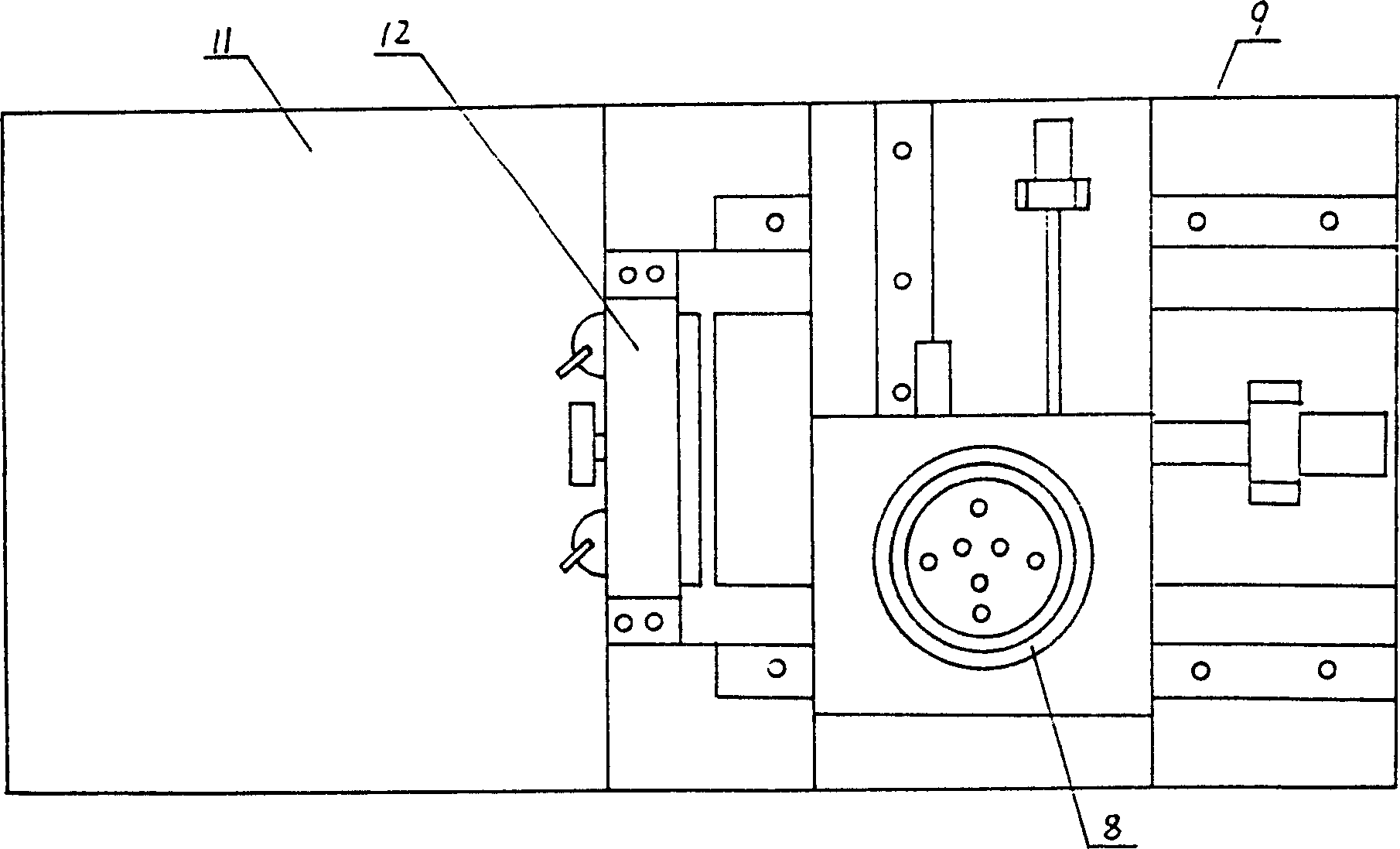

[0028] figure 1 Among them, 1 is the light source projection system, 2 is the shooting system, 3 is the rotating platform, 4 is the metal object to be tested, 5 is the control computer, the light source projection system 1, the shooting system 2, the rotating platform 3 and the metal object 4 to be tested are all set On one bed, it is controlled and measured by a control computer. The method for microscopic three-dimensional imaging of metal surface scratches is characterized in that it comprises the following steps:

[0029] --Design the grating pattern used in this system according to the requirements, and print it into a color film;

[0030] --Fix the metal object to be microscopic three-dimensional imaging on the high-precision rotating platform, the high-precision rotating platform

[0031] And the camera with the microscope lens is connected with the computer control system, and the preset values required for shooting the object are preset to the computer, including ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com