Process for treating waste water for fumaric acid production

A treatment process and technology for producing wastewater, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of undiscovered wastewater treatment methods, incomplete treatment, and serious air pollution and other issues to achieve quick results, low cost, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

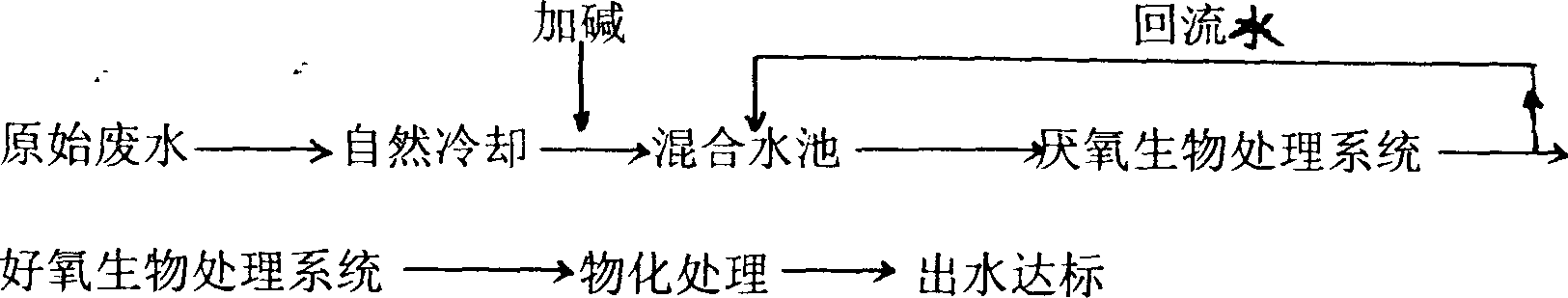

[0018] The CODcr content in the original wastewater is 100000mg / l, after natural cooling, the CODcr content in the wastewater is 72000mg / l, the pH value is adjusted to 4.0 by adding sodium hydroxide, and the water volume is adjusted in the mixing pool, so that the adjusted CODcr in the water is 12000mg / l l, PH=6.5, there is a heating device in the mixing tank to raise the water temperature to 30-40°C, and then enter the anaerobic biological treatment system.

[0019] The anaerobic biological treatment system adopts the UASB+AF method. The water distribution at the bottom is uniform, and there is sludge inside. The upper part of the structure has a water collection device and a biogas collection device. The wastewater stays in the anaerobic stage for 15 days, and the effluent enters the sedimentation tank. After precipitation, part of the supernatant flows back into the mixing tank with a reflux ratio of 3:1 (reflux water: original wastewater), and the other part flows into the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap