Control device for zero-voltage conversion step-up power factor correcting circuit

A power factor correction and control device technology, applied in output power conversion devices, high-efficiency power electronic conversion, electrical components, etc., can solve problems such as AC input voltage peak value can not be too high, inductance L has noise, oscillation and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

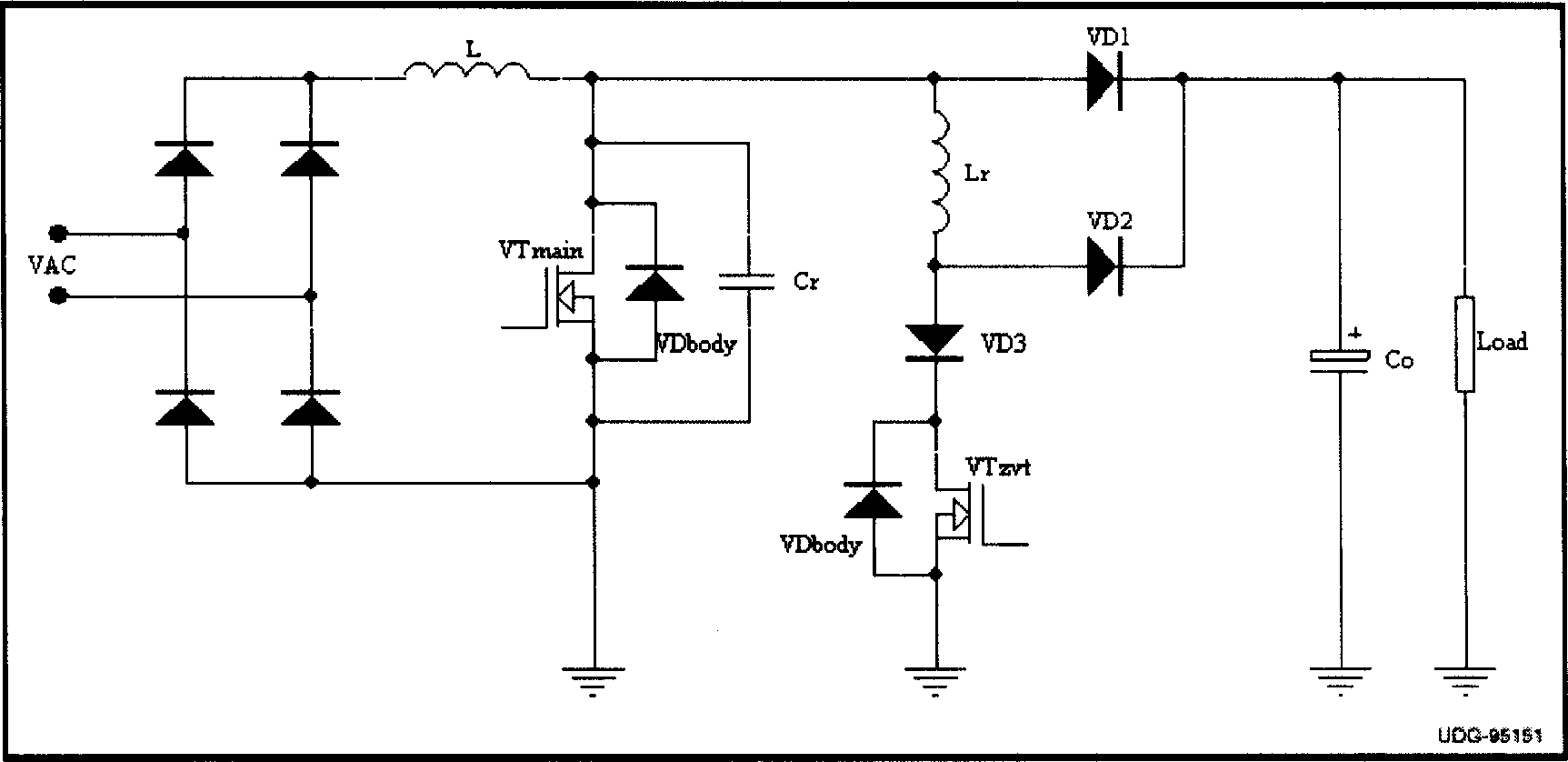

[0024] figure 1 , figure 2 , image 3 Corresponding descriptions have been given in the background art section.

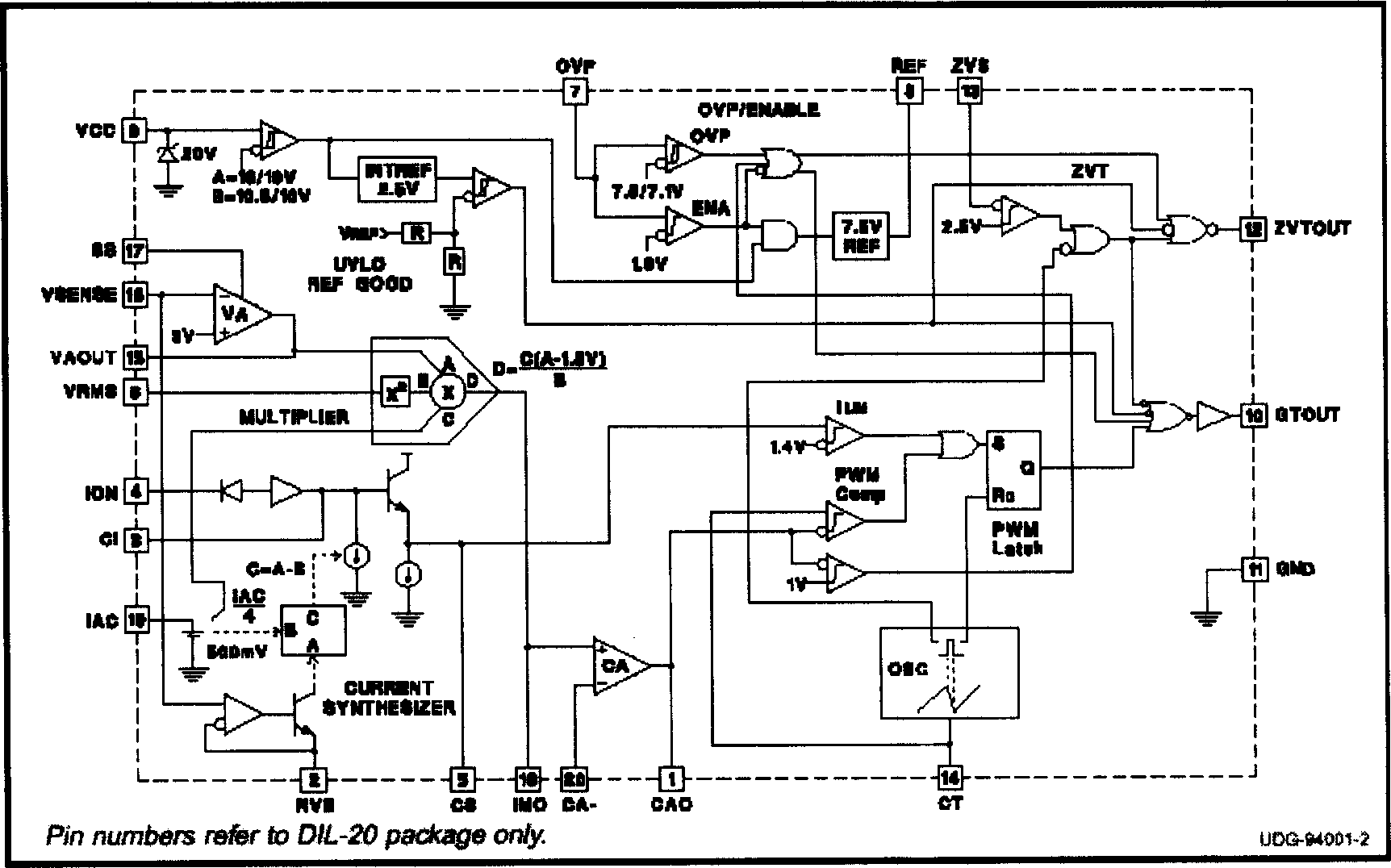

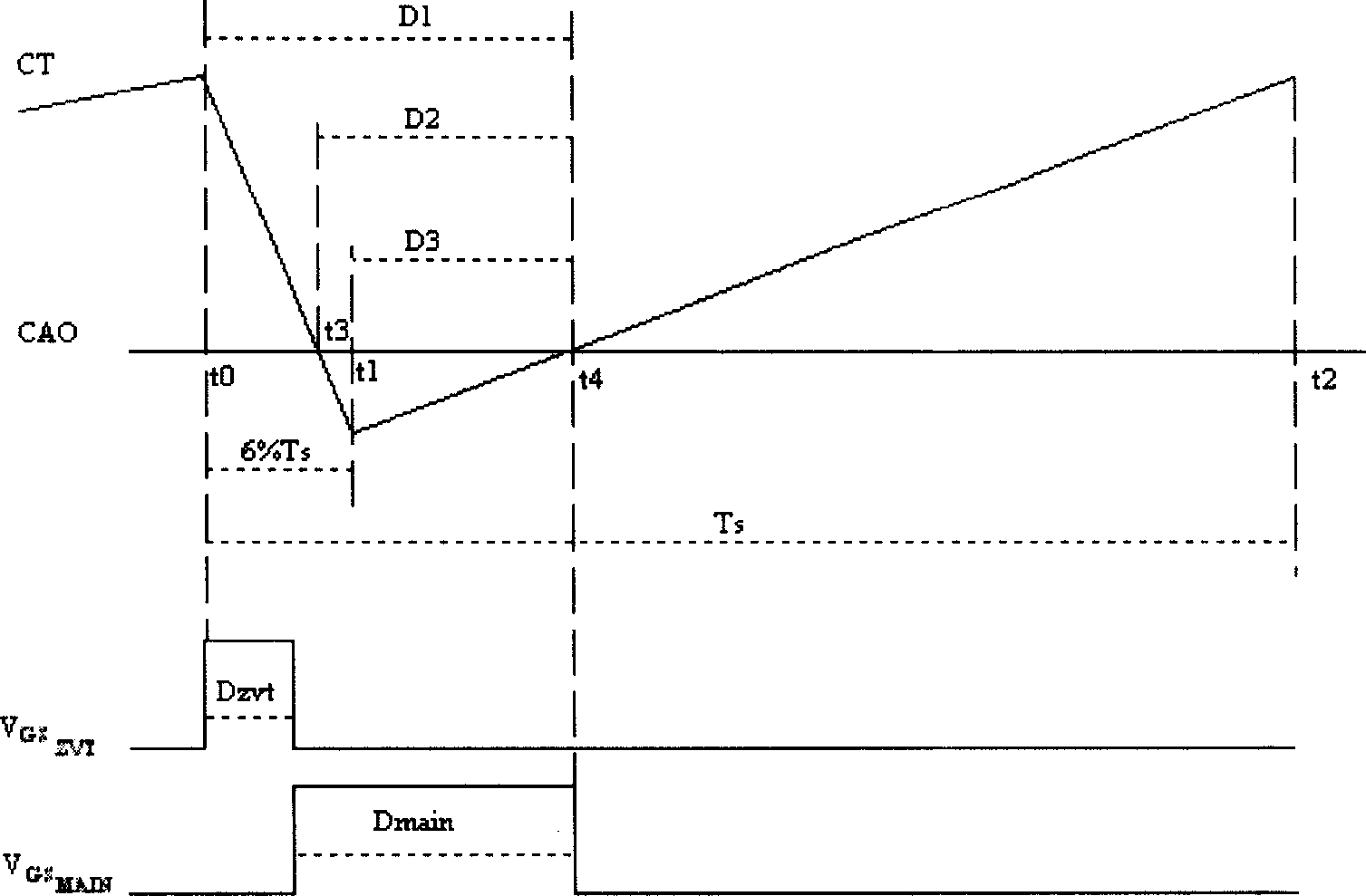

[0025] Figure 4 For realizing the functional block diagram of the present invention: supervisory drain-source terminal voltage detection circuit 101, V DS MAIN is the main drain-source terminal voltage, ZVS is its detection signal, when V DS MAIN When it is low, ZVS is low level, otherwise it is high level, and the conversion value of high and low levels is determined by the logic circuit characteristics in the main and auxiliary pipe drive pulse distribution circuit 103; the PWM comparator circuit 102 generates a DRV with a duty cycle of D2 Signal; the main and auxiliary pipe drive pulse distribution circuit 103 is a circuit for realizing the construction of the auxiliary pipe drive signal VTzvt and the main pipe drive signal VTmain from the DRV, and satisfies the following three conditions:

[0026] 1. Auxiliary pipe drive signal: V GSZVT =DRV·ZVS,

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com