Method for constructing steel bar concrete bottom pillars for space mining process for middle thick mine body

A technology of reinforced concrete and mining methods, which is applied in ground mining, underground mining, special mining, etc. It can solve the problems of narrow underground construction sites, inability to mechanize construction, and complicated reinforced concrete construction processes, so as to reduce mining losses and reduce Dilution of mining loss, improvement of ore grade and the effect of enterprise benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

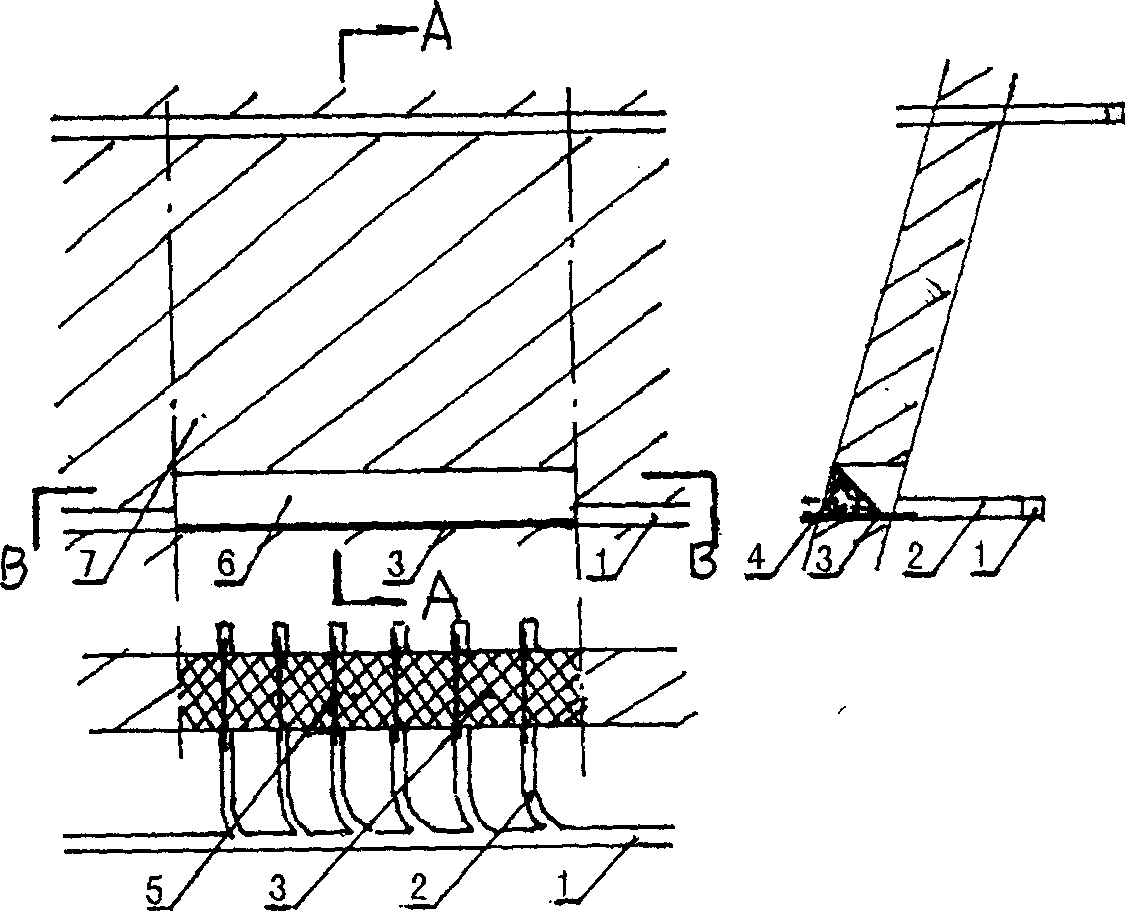

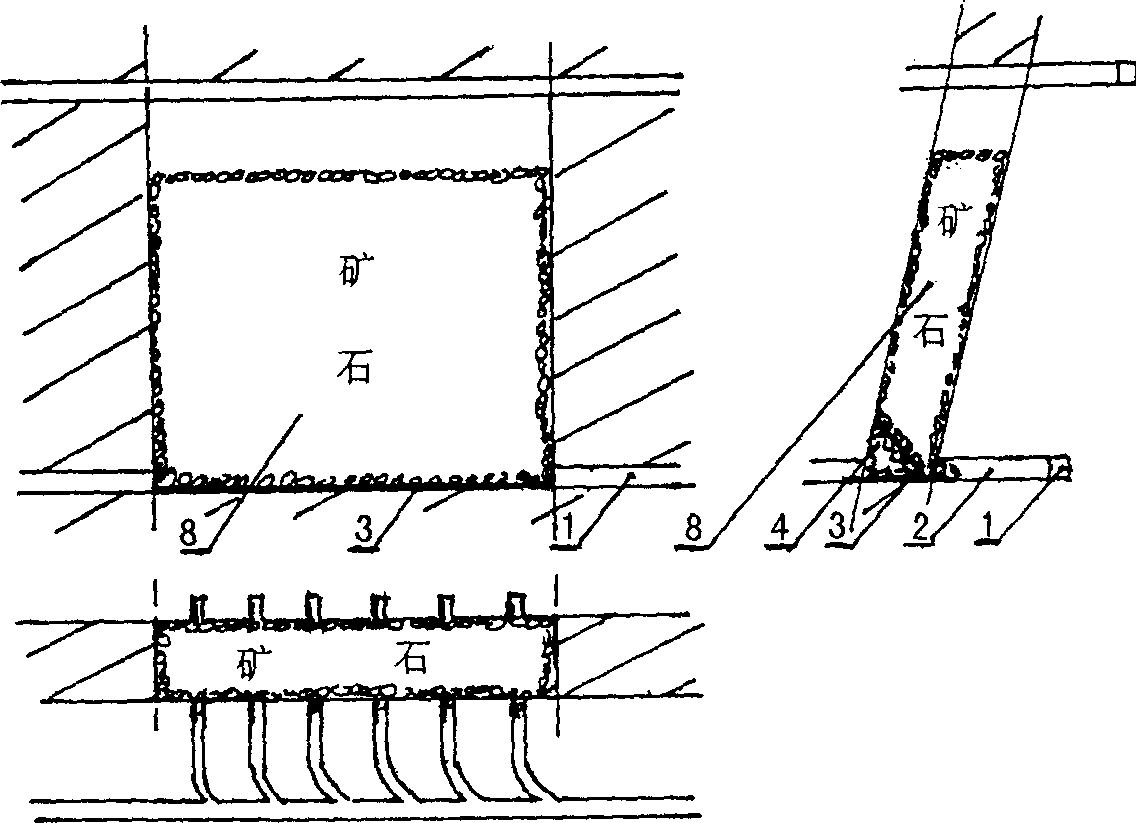

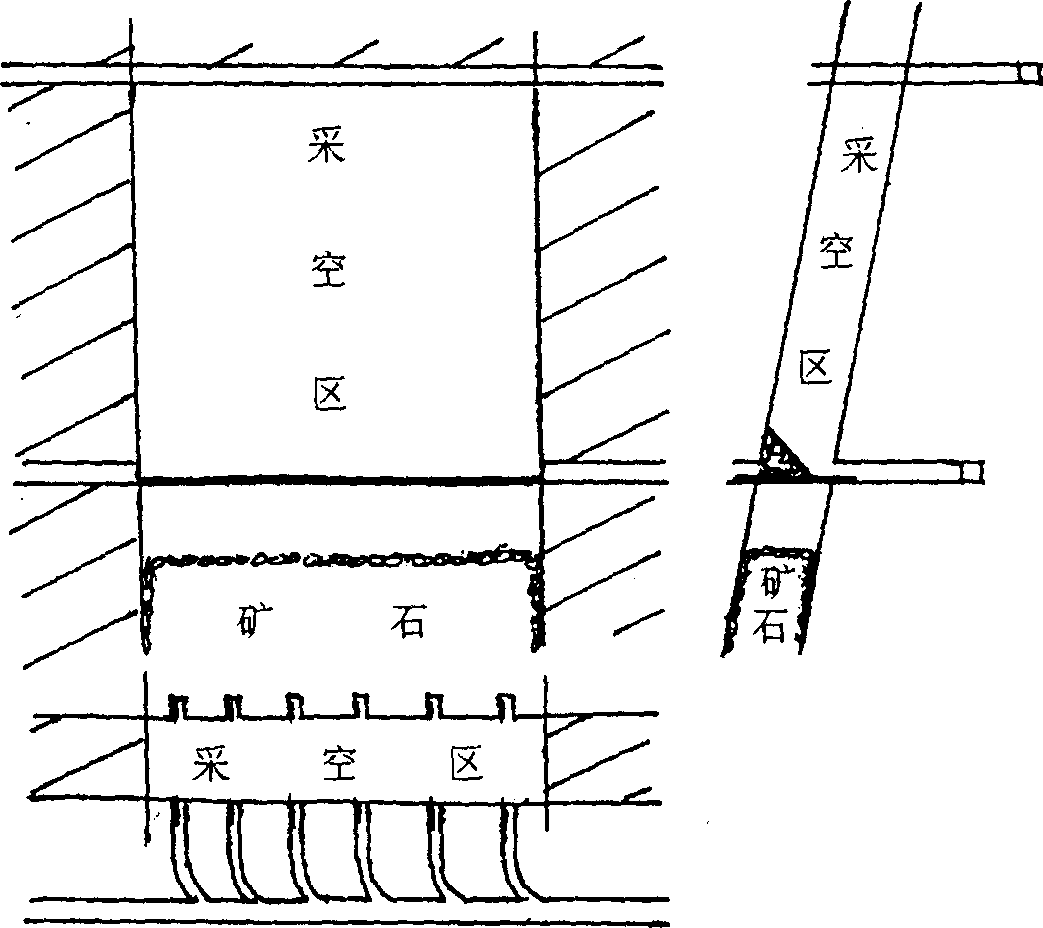

[0010] In the 3741 stope of the middle section of 110 in the Yunxi mining area of Gaoyao Hetai Gold Mine in Guangdong Province, there is a section of about 20m long rich ore bag with an average grade of 25.72g / t. The implementation steps are shown in the figure: (1) Stope cutting and construction artificial bottom pillar; 2) Mining in this stope; (3) The end of mining in this stope and the end of top column mining in the corresponding lower stope. Constructing a 5m×40m artificial bottom column requires about 60-120m of concrete 3 , average per m 3 The cost is 350-550 yuan, and it generally takes about 10-20 days to lay anchor rods, lay steel bars and pour concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com