Polar armature

A technology of pole electricity and current, applied in the field of pole armature, can solve the problems of large footprint and insufficient cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

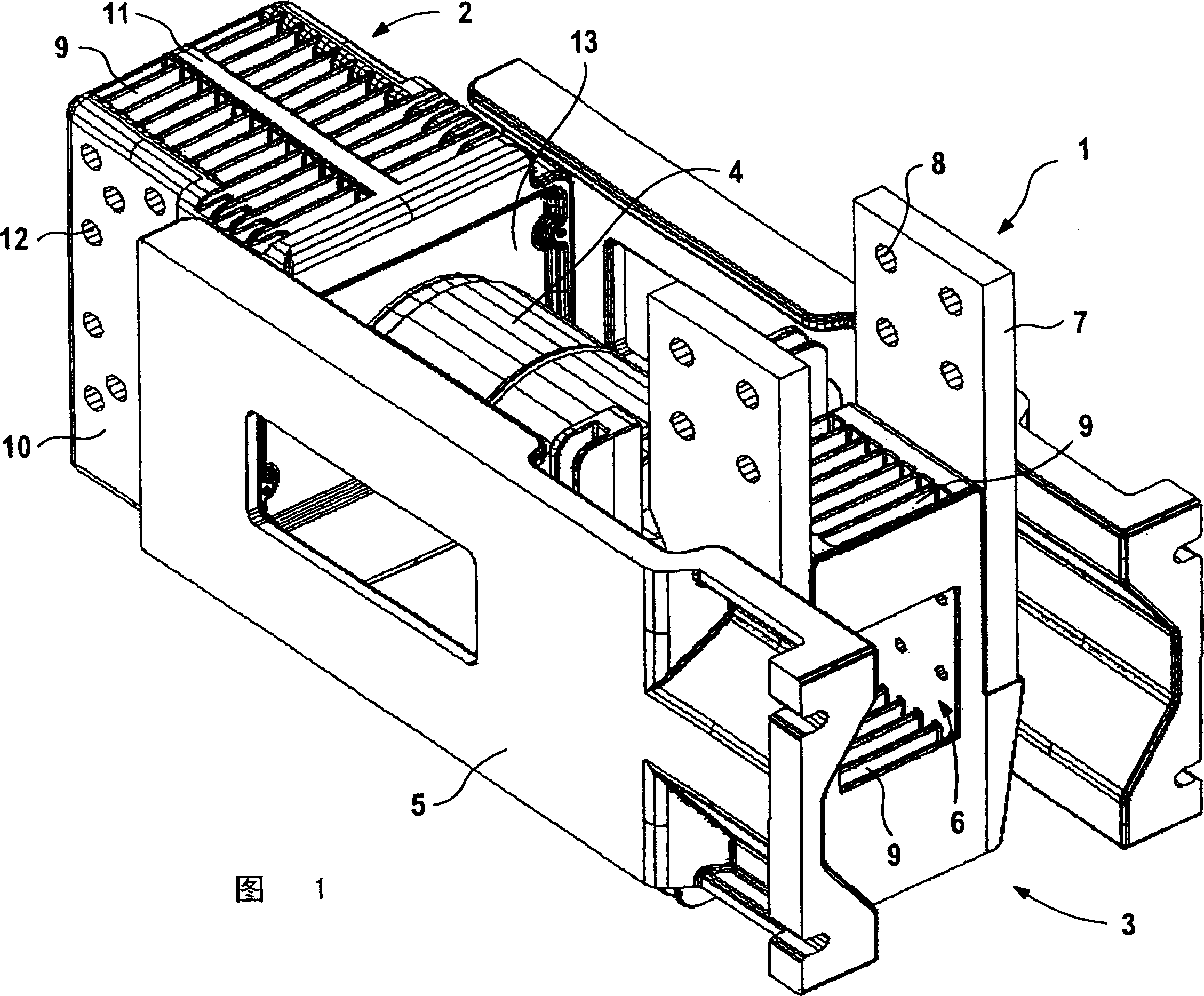

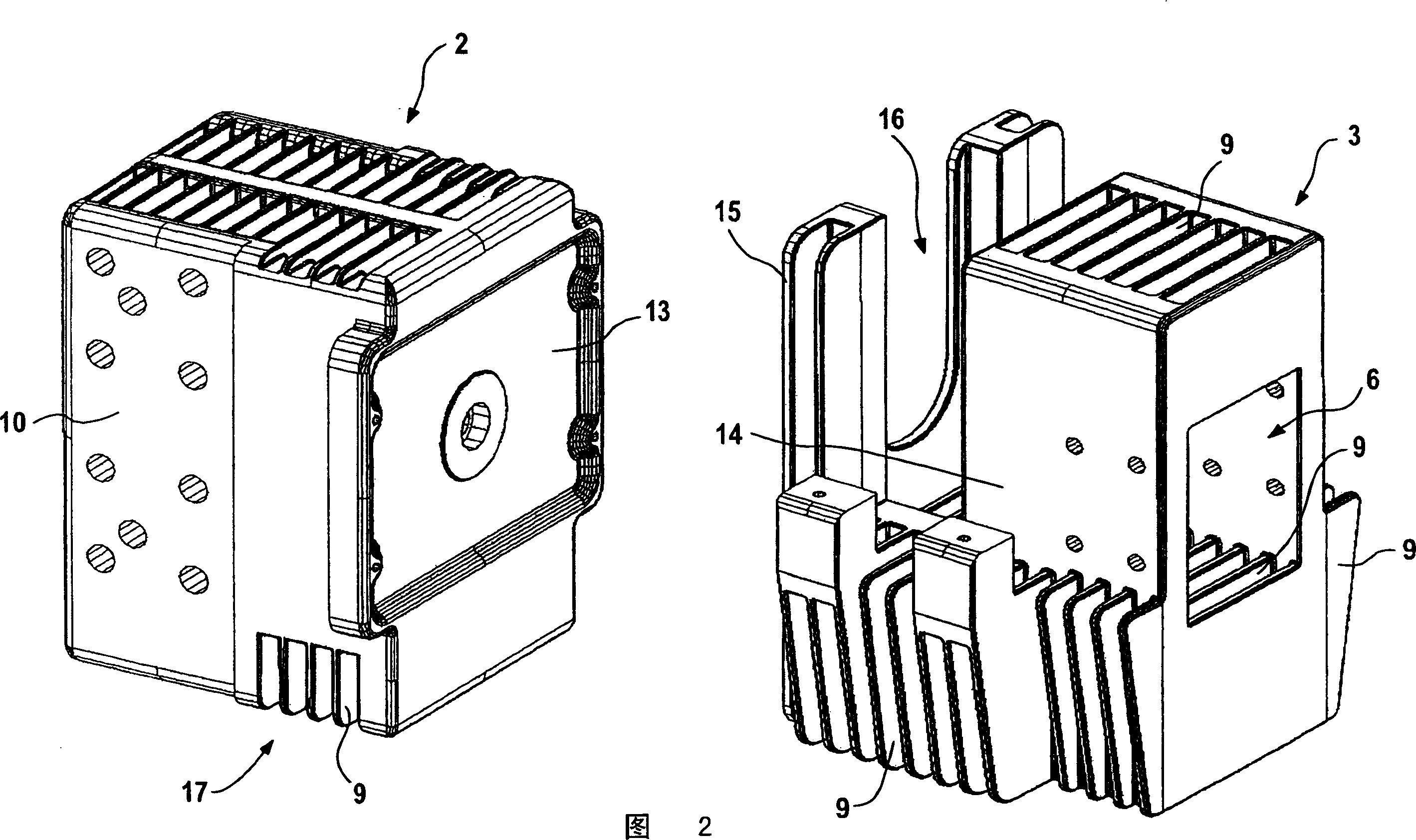

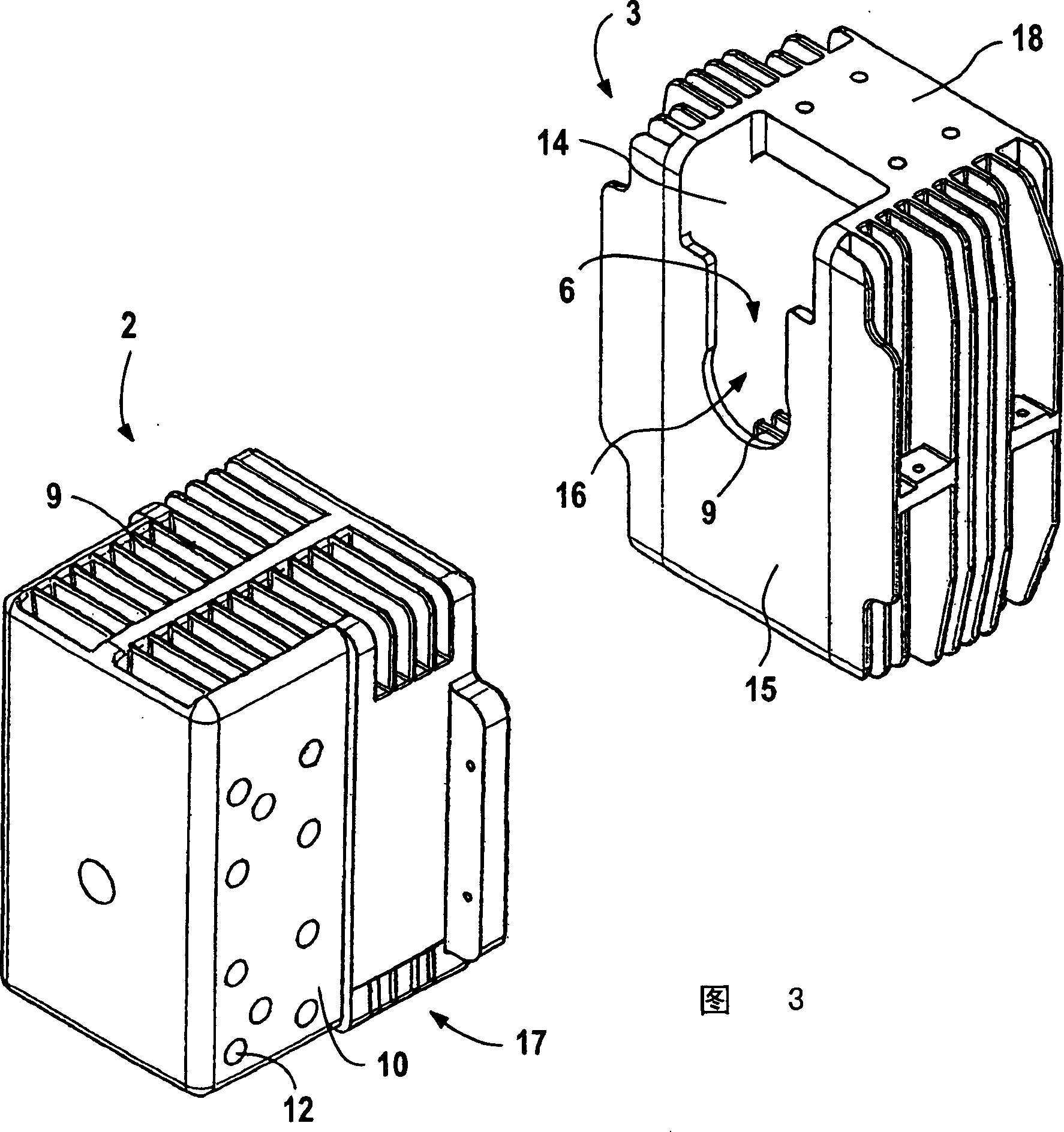

[0030] FIG. 1 shows a switching pole of a circuit breaker 1 with an embodiment of a pole armature according to the invention, which consists of a pole head 2 and a pole carrier 3 . Arranged between the pole head 2 and the pole carrier 3 is an arc quenching unit 4 which, in the exemplary embodiment shown, is a vacuum switch. For the mechanical connection and support of the pole armature, a pole shell 5 made of non-conductive insulating material is provided, which extends to both sides of the vacuum switch 4 and connects to the pole head 2 and the pole head 2 at the connection point provided for this purpose. Connect with pole support 3.

[0031] The pole support 3 has an orifice 6 through which the operating rod or other parts of the operating mechanism can pass in the direction of the vacuum switch 4 in order to push the moving contact of the vacuum switch 4 into the contact position or in the non-contact position Break the current.

[0032] Furthermore, two busbars 7 with h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com