Refuelable electrochemical power source capable of maintaining in constantly full and method of using same

A supplementary fuel and electrochemical technology, applied in the field of electrochemical power supply, can solve the problems of long charging time, inability to mechanically seal dendrites, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

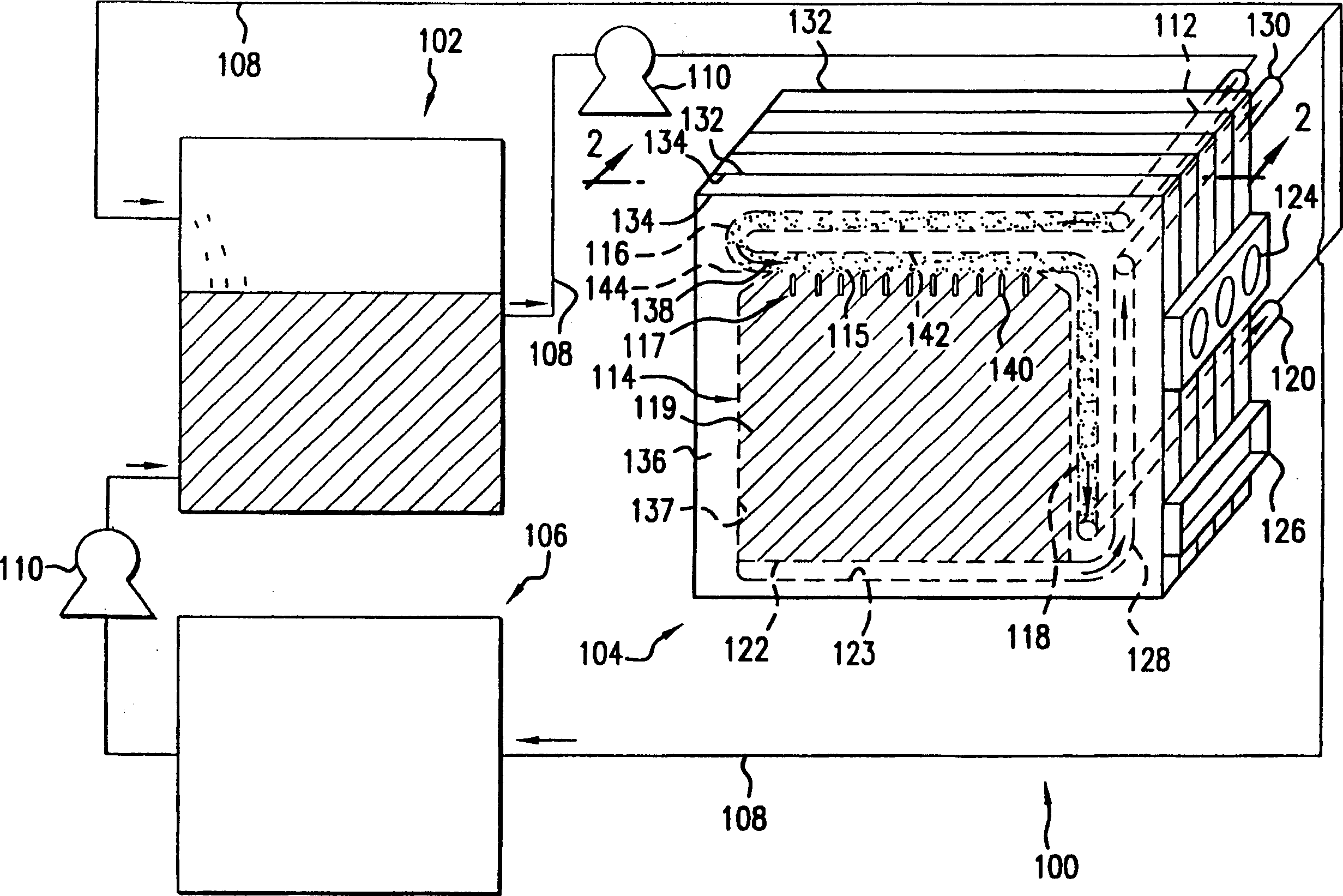

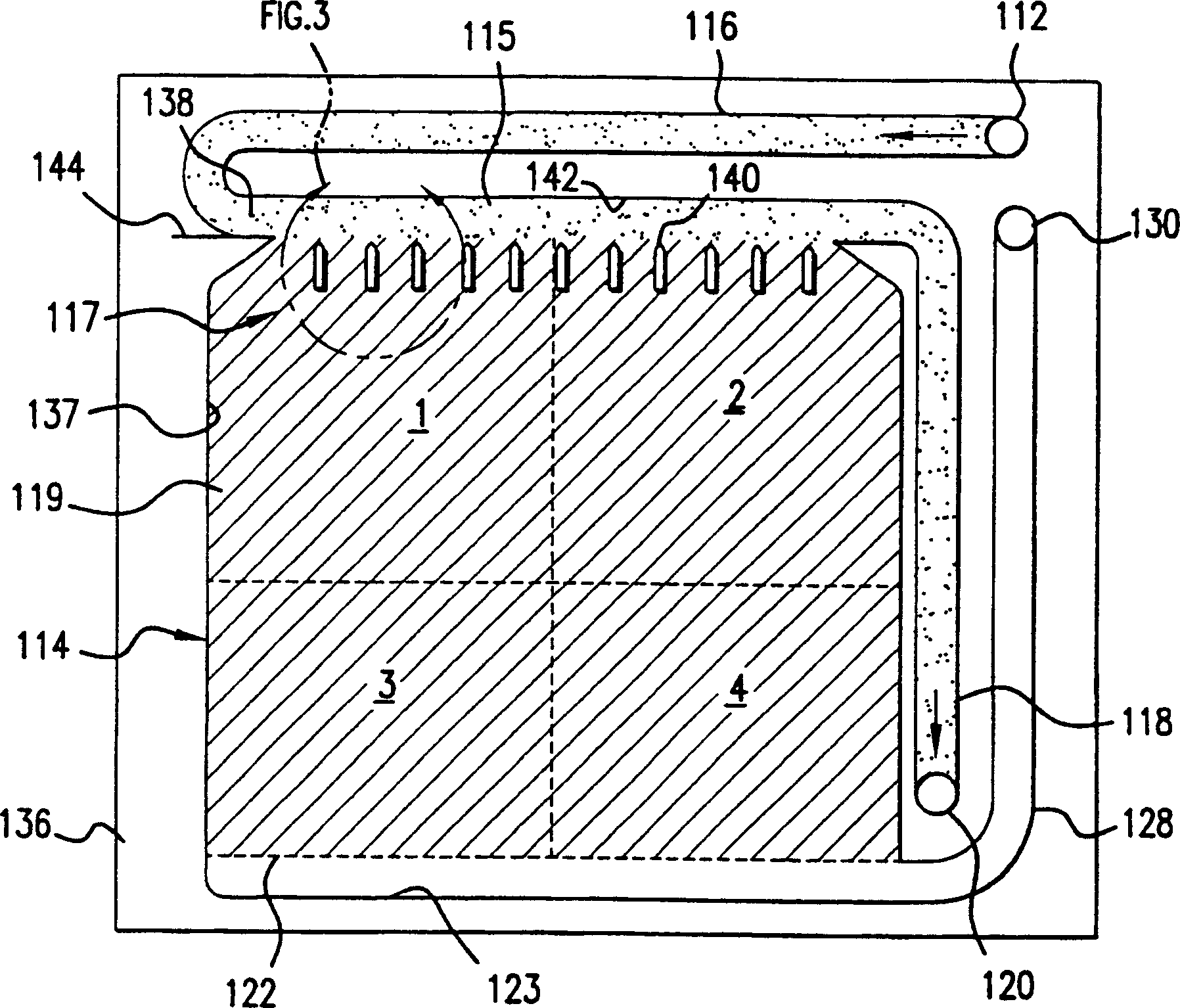

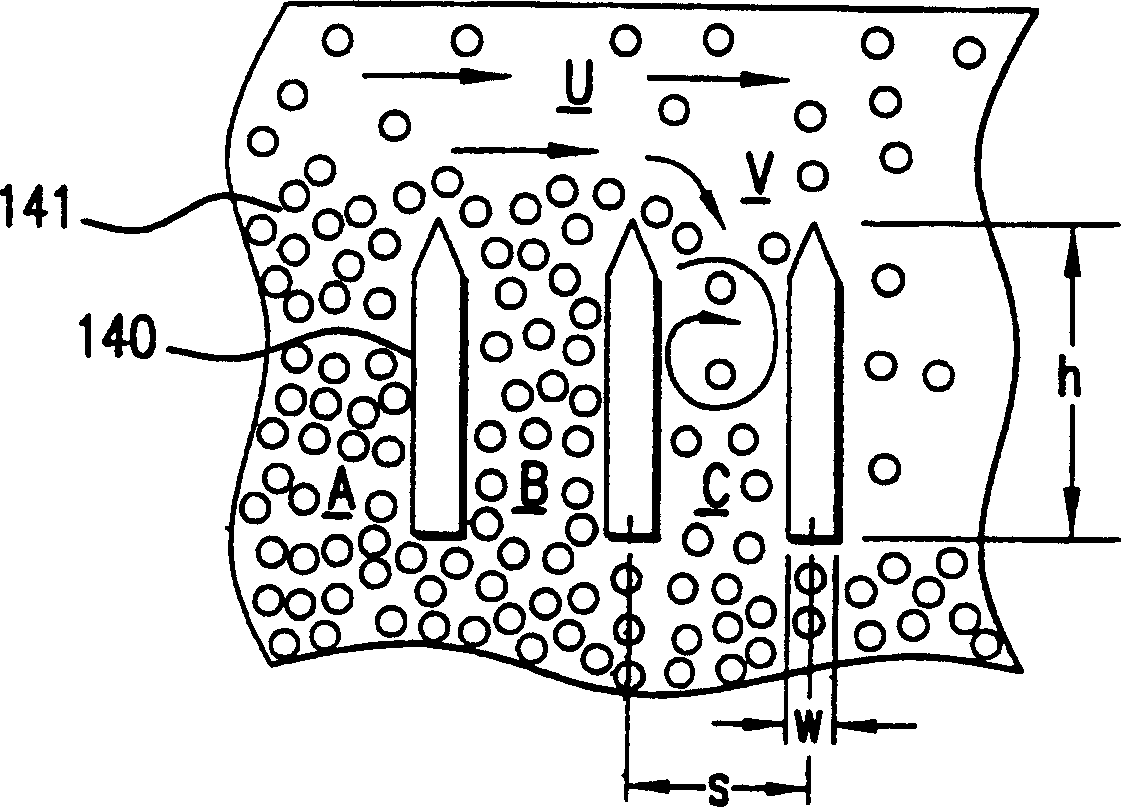

[0036] All examples of the invention presented here relate to zinc / air fuel cells and systems. It is important to note, however, that the invention can be applied to other types of power sources, fuel cells and / or batteries. For example, the present invention can be applied to other metal / air fuel cells, such as aluminum / air fuel cells, lithium / air fuel cells or iron / air fuel cells, but is not limited thereto. More generally, the invention may be applied to any electrochemical device employing solid particulate matter as an oxidant or reductant, or to systems employing oxidants other than air, such as oxygen, hydrogen peroxide, bromine or capable of carrying soluble oxidants of liquid. The invention can also be applied to metal recovery systems. An example of a metal recovery system is one that uses electricity to recover zinc from an aqueous solution. Therefore, the examples used herein to describe zinc / air fuel cells should not be construed as limiting the scope and bread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com