Burner suitable for oil-burning cremator and its usage

A burner and cremation machine technology, applied in the direction of burners, lighting and heating equipment, etc., can solve the problems of insufficient fuel combustion, poor fuel atomization effect, and reduced work efficiency, so as to improve rigidity, save energy, and improve work efficiency. efficiency effect

Inactive Publication Date: 2003-07-30

王清波

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The main disadvantages are that the fuel atomization effect is poor and the rigidity of the flame is weak, resulting in insufficient fuel combustion, which not only wastes fuel, reduces work efficiency, but also pollutes the environment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

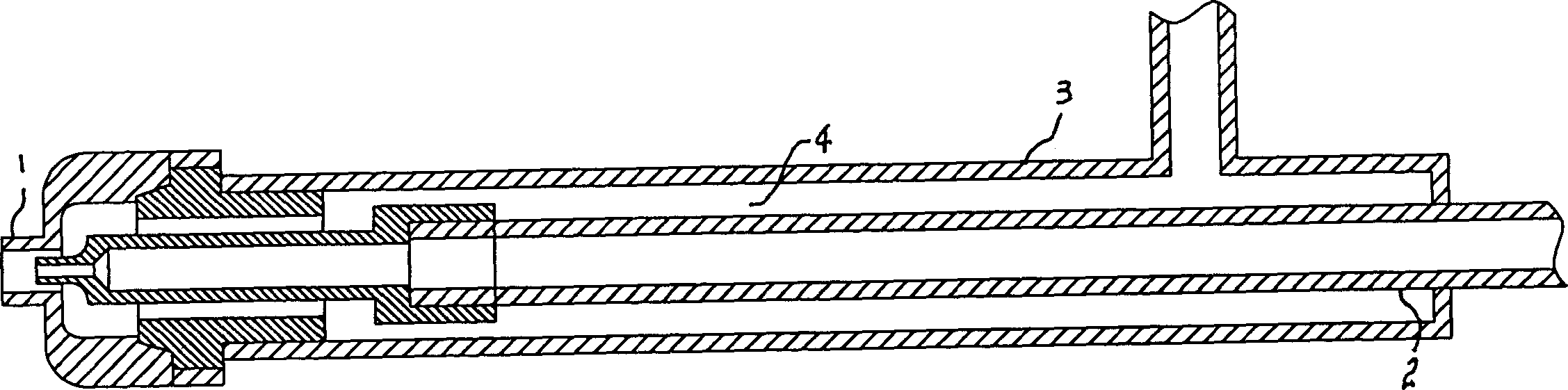

[0012] As shown in the figure, the present invention includes an oil pipe 2 and an air pipe 3 with a nozzle 1, the oil pipe 2 is set inside the air pipe 3, and there is a gap between the outer wall of the oil pipe 2 and the inner wall of the air pipe 3 to form an air passage 4 ; The oil pipe 2 is connected with fuel oil, and the air pipe 3 is connected with compressed air, the pressure of the compressed air is 0.2MPa-2Mpa, and the cross section of the nozzle 1 is rectangular.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

The burner suitable for oil burning cremator includes oil pipe and air pipe with nozzle, and the oil pipe is set in the air pipe with interval as air channel in between. The oil pipe is for fuel oil to flow and the air pipe is for compressed air of 0.2-2 MPa pressure to flow. The present invention has the advantage that when compressed air is led into the air pipe, the fuel oil at the nozzle is jetted by the negative pressure produced by the compressed air from the nozzle and atomized instantaneously into extremely small oil drops and this results in high burning efficiency, flame temperatureas high as 1500 deg.c, less exhaust of fume, SO2, H2S, NOx, NH3 and CO, raised flame rigidity and shorted corpse cremating time to 30-45 min.

Description

technical field [0001] The invention relates to a burner and its use method, in particular to a burner suitable for fuel cremation machines and its use method. Background technique [0002] Most of the burners of the used fuel oil cremation machines at home and abroad are single oil pipe and the nozzle that is arranged on this oil pipe outlet at present. When in use, fuel is supplied to the oil pipe through the oil pump, and the fuel oil with pressure supplied by the oil pump is sprayed through the nozzle of the oil pipe to be atomized naturally, and at the same time, air is supplied to the atomized fuel to help combustion. Using this burner to incinerate a corpse in this way consumes an average of 30 kilograms of fuel oil, and the burning time takes about 45--80 minutes. The main disadvantages are that the fuel atomization effect is poor and the rigidity of the flame is weak, resulting in insufficient fuel combustion, which not only wastes fuel, reduces work efficiency, bu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): F23D11/14

Inventor 王清波

Owner 王清波

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap