Piezoelectric resonator and its making process

A technology for piezoelectric resonators and manufacturing methods, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc., capable of Address issues such as few proposals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In the following, specific embodiments of the present invention will be described in detail with reference to the accompanying drawings, so as to deepen the understanding of the present invention.

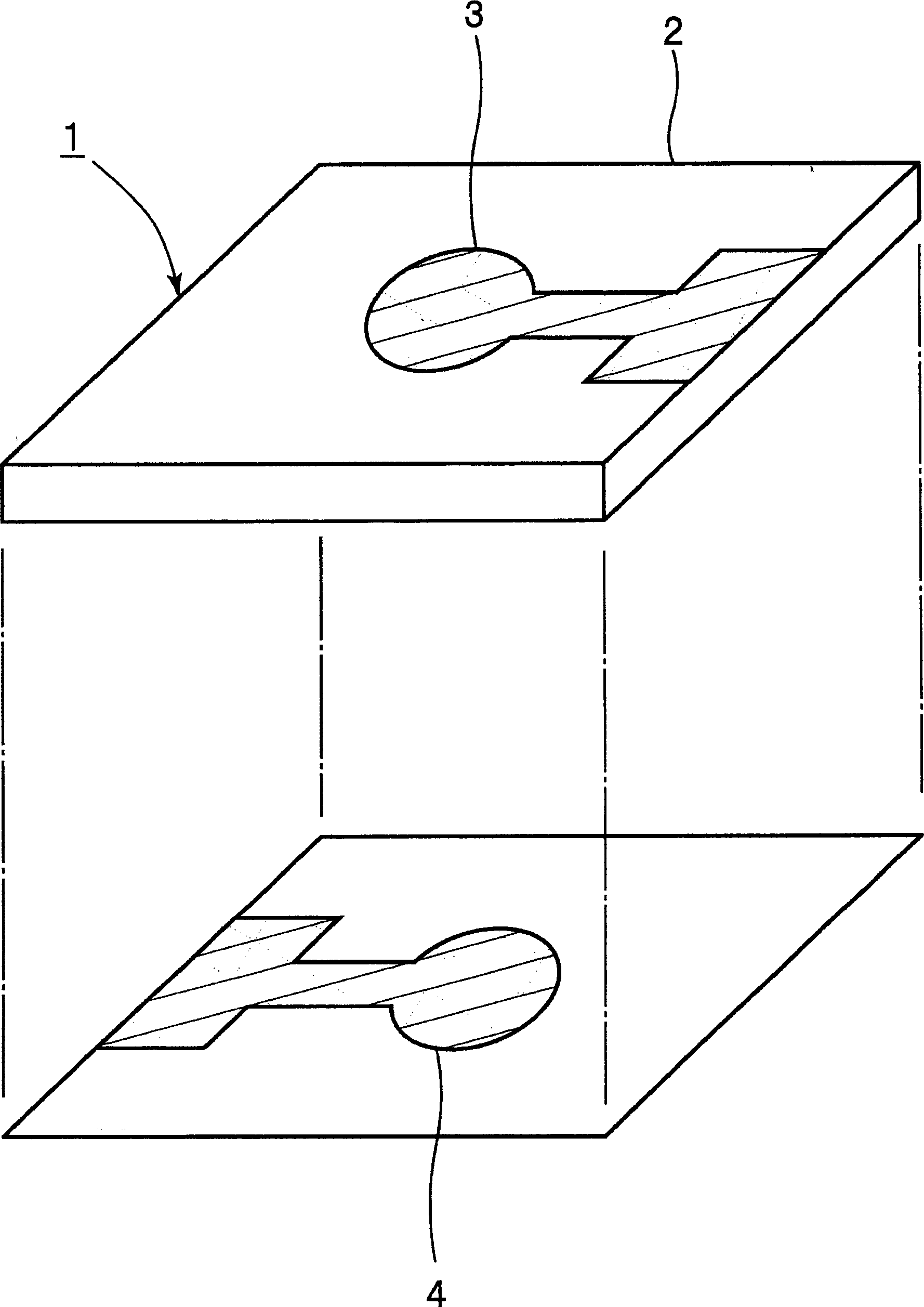

[0023] figure 1 It is a schematic perspective view of a thickness longitudinal piezoelectric resonator for explaining one embodiment of the present invention. The piezoelectric resonator 1 has a plate-shaped piezoelectric body 2 . The piezoelectric body 2 is made of appropriate piezoelectric ceramics such as lead titanate zirconate-based ceramics. Polarization is performed in the thickness direction of the piezoelectric body 2 . Furthermore, first and second vibrating electrodes 3 and 4 are formed on both main surfaces of the piezoelectric body 2 . The first and second vibrating electrodes 3 and 4 face each other via the piezoelectric body 2 , and the first and second vibrating electrodes 3 and 4 are formed on a part of the upper surface and the lower surface of the piezo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com