Dry type transprinted ceramic adhering pattern paper

A technology for decals and ceramics, applied in decorative arts, processes for producing decorative surface effects, etc., and can solve problems such as residues, incomplete combustion, poor thermoplasticity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

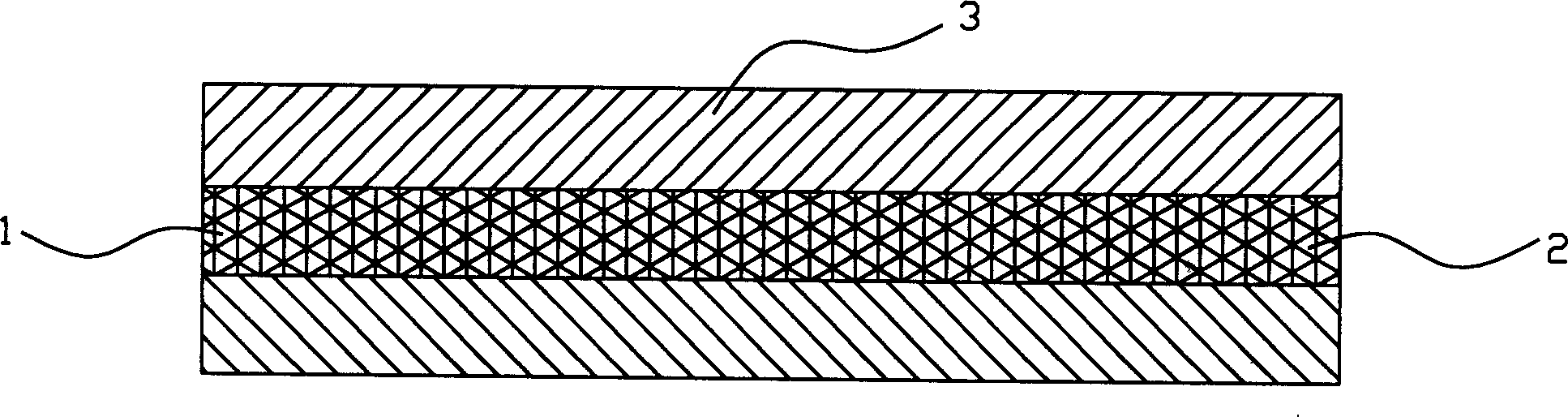

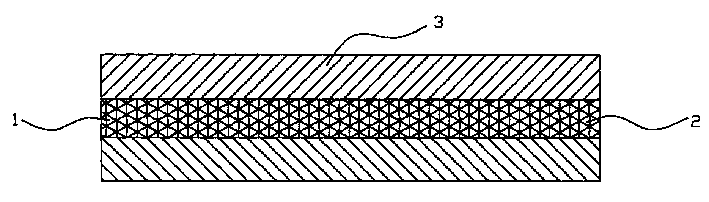

Image

Examples

example 1~10

[0028] Tables 1 and 2 describe the composition of the protective coating and print media. The materials were produced by mixing the raw materials through a dissolver for 30 minutes without cooling.

[0029] protective coating

[0030] colored glue

example 16

[0032] Use 100T polyester screen to apply colored glue on the special release paper by indirect screen printing (Example 11). After complete drying, the varnish was applied by indirect screen printing using a 18T polyester screen (Example 8). Once the decal is dry, it can be removed by hand from the paper and submerged in water for 1 minute. Then apply the isolation glue with a Shore hardness of 65 on the porcelain plate to remove the water stains below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com