Method of producing thiourea using acidic waste gas discharged from oil refinery

An acid waste gas, refinery technology, applied in organic chemistry and other directions, can solve the problems of high cost of thiourea and environmental pollution by barium sulfide residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

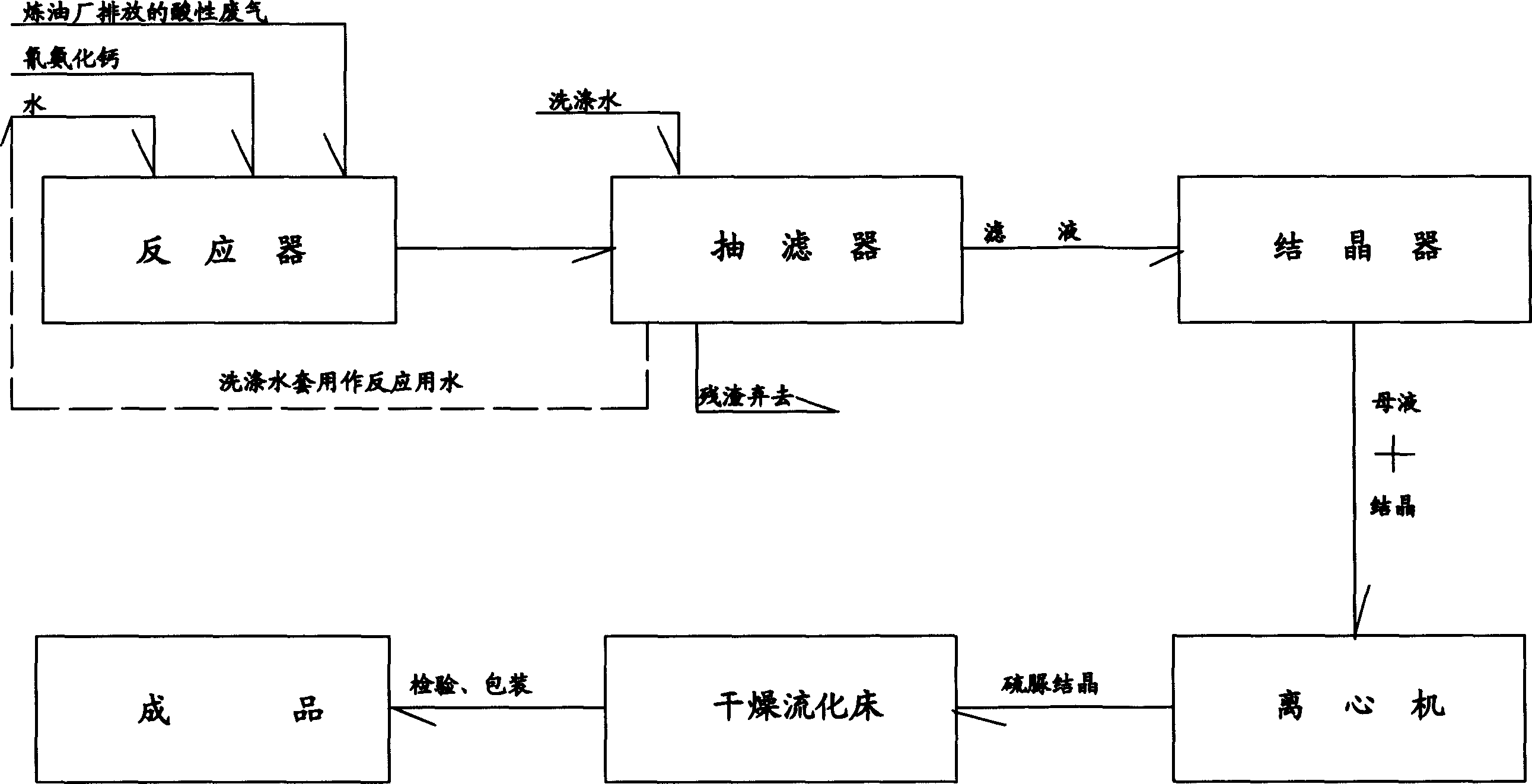

Method used

Image

Examples

Embodiment 1

[0025] Directly use the acid waste gas discharged from the refinery and calcium cyanamide to produce thiourea; the composition of the acid waste gas discharged from the refinery in this batch is: hydrogen sulfide 60±5%, air 10±3%, carbon dioxide 3±0.5%, Ethane 2±0.5%, Methane 0.2±0.05%, Propylene 0.2±0.05%, Propane 0.09±0.02%, Ethylene 0.05±0.02%, Carbon Monoxide 0.09~±0.03%, The balance is trace butene, anti-butene, normal Butane and isobutane;

[0026] The specifications of calcium cyanamide are: effective nitrogen content 17.35%, calcium carbide content 1.0%, aperture 850μm sieve residue ≤ 3%, appearance black powder.

[0027] In the above method, its production process is divided into calcium hydrosulfide process, thiourea synthesis process and post-treatment process, wherein:

[0028] (1) Calcium Hydrosulfide Process

[0029] Raw material weight ratio calcium cyanamide: water = 550kg: 8000kg; put in water first, add calcium cyanamide under stirring, add to the generated...

Embodiment 2

[0045] Directly use the acid waste gas discharged from the refinery and calcium cyanamide to produce thiourea; the composition of the acid waste gas discharged from the refinery in this batch is: hydrogen sulfide 80±5%, air 20±2%, carbon dioxide 10±1%, Ethane 8±1%, Methane 0.5±0.1%, Propylene 0.4±0.05%, Propane 0.2±0.02%, Ethylene 0.2±0.01%, Carbon Monoxide 0.15±0.05%, The balance is trace butene, anti-butene, n-butene alkanes and isobutanes;

[0046] The specifications of calcium cyanamide are: effective nitrogen content ≥ 20%, calcium carbide content ≤ 0.2%, sieve residue ≤ 3% with aperture 850μm, appearance of black powder.

[0047] (1) Calcium Hydrosulfide Process

[0048] Raw material weight ratio calcium cyanamide: water / thiourea synthesis process lotion = 650kg: 8000kg; the acid waste gas discharged from the refinery is passed into the acid waste gas discharged from the refinery under stirring at 70-80°C, and the calcium hydrosulfide content in the reaction solution re...

Embodiment 3

[0053] Directly use the acid waste gas discharged from the refinery and calcium cyanamide to produce thiourea; the effective nitrogen content of calcium cyanamide is ≥19%, the content of calcium carbide is ≤0.5%, and the sieve residue with an aperture of 850 μm is ≤3%; calcium cyanamide: Thiourea synthesis process lotion = 600kg: 8000kg; 80 ~ 90 ° C under stirring to produce calcium hydrosulfide; thiourea synthesis calcium hydrosulfide: calcium cyanamide = 1: 1.1 (molecular ratio); Stir at 80 ~ 90 ° C Next, react for 3h to synthesize thiourea; the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com