Large power generator stator winding terminal part vibration on line monitoring method

A generator stator and winding end technology, applied in the direction of instruments, etc., can solve problems such as unfavorable computer analysis records, complicated receiving equipment, and failure to obtain the direction of vibration, etc., achieve large market application prospects, solve economic losses, and simple design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

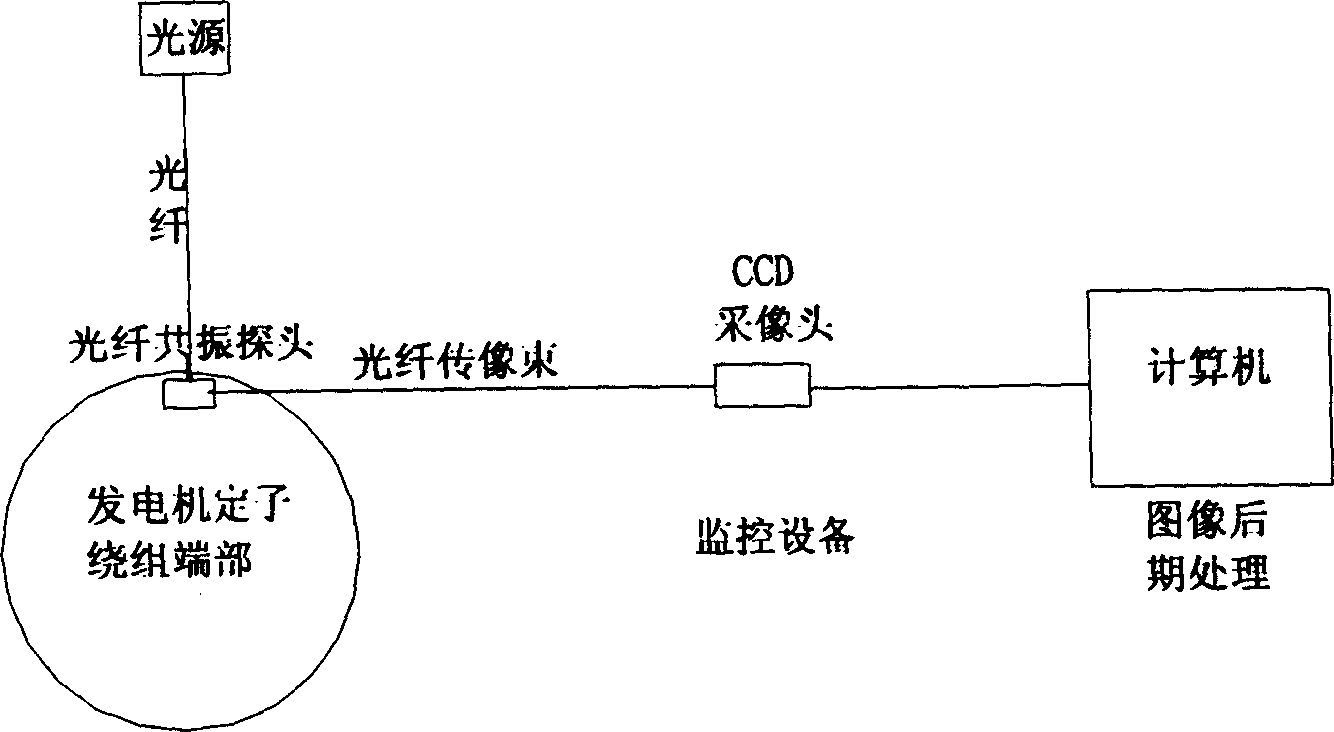

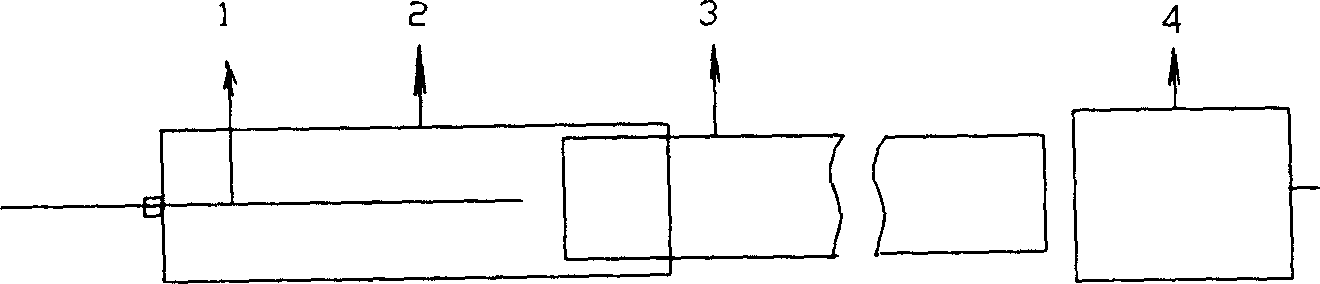

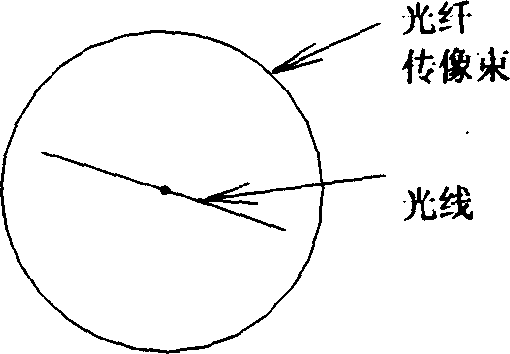

[0017] The present invention uses the method of optical fiber resonance to monitor the vibration state of the generator stator winding end on-line. The process is as follows: figure 1 Shown. An optical fiber resonance probe is installed at the end of the generator stator winding. The structure and transmission principle of the optical fiber resonance probe are as follows figure 2 Shown. In the optical fiber resonance probe, the fixed end of the vibrating fiber 1 is connected to an external light source, and the circular fiber image transmission bundle 3 is placed at a distance from the free end of the vibrating fiber. The resonance probe protective sleeve 2 transmits the images of the resonant fiber 1 and the optical fiber image bundle 3 The receiving ends are fixed together. The optical fiber image transmission bundle 3 is connected to an exter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com