Plug socket for pin grid array plug-in board

A pin array and socket technology, applied in the field of sockets, can solve the problems of inability to align electronic plug-ins of different sizes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

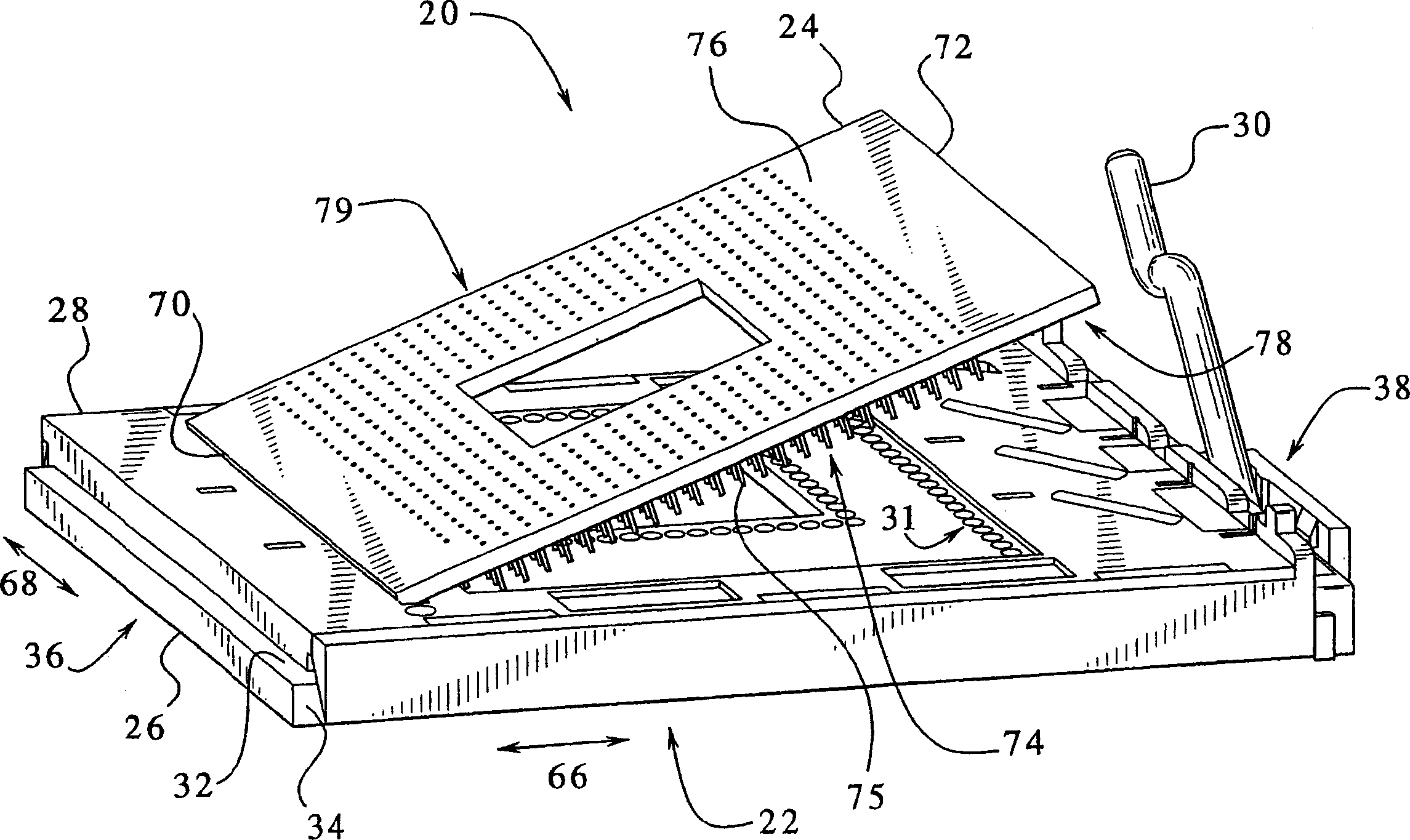

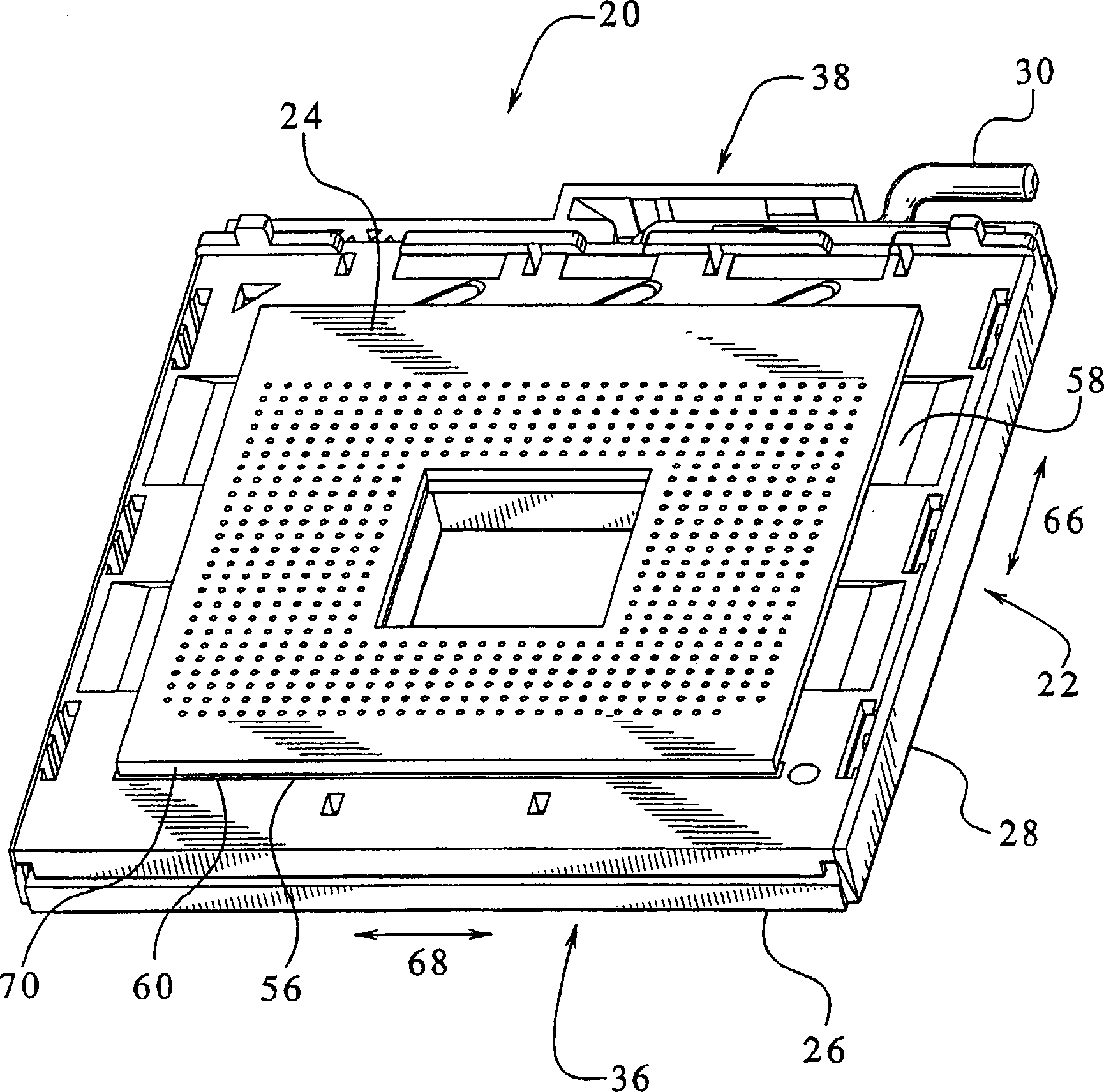

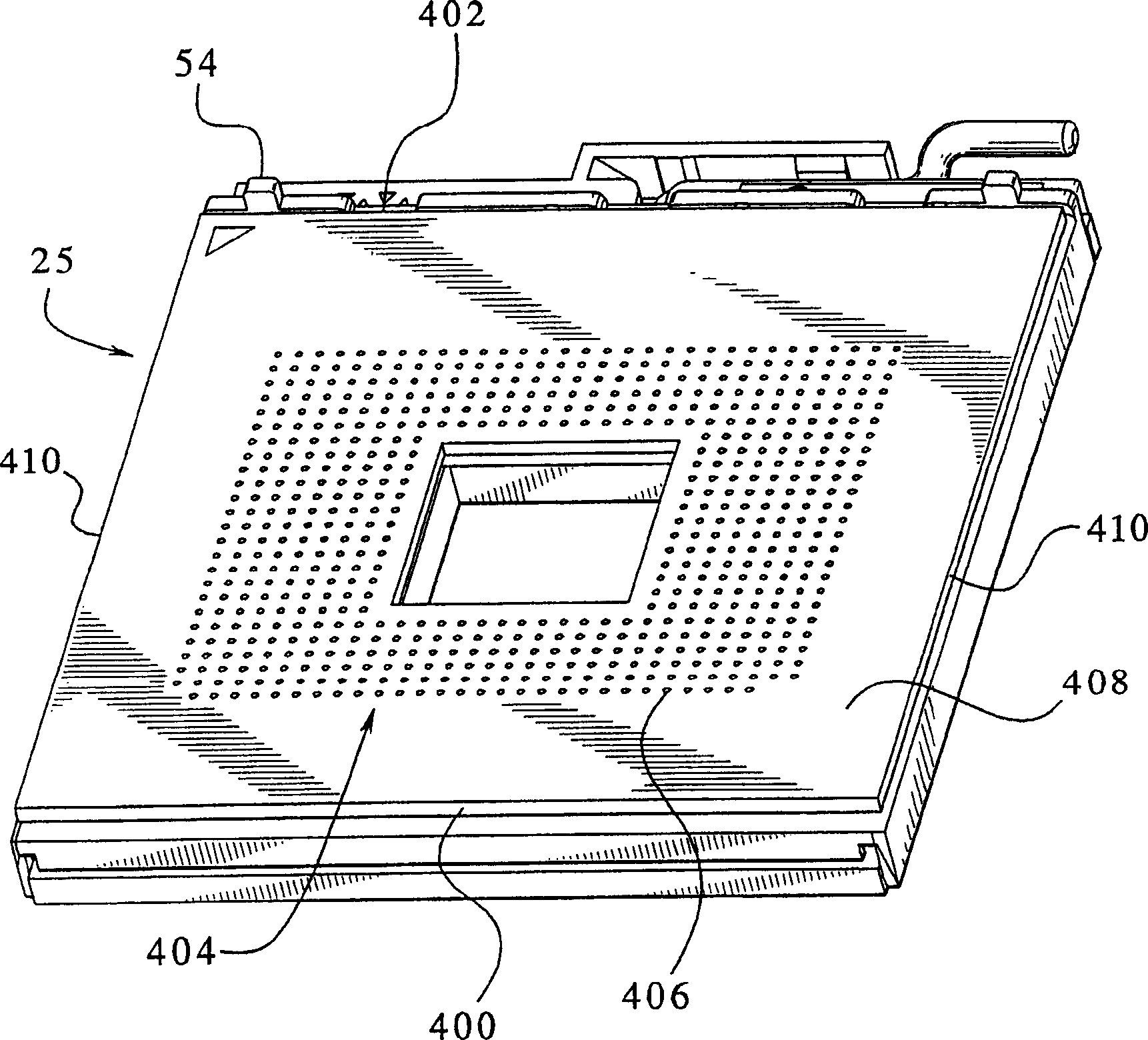

[0024] figure 1 An embodiment of the PGA component 20 when the first electronic package 24 is mated with the socket 22 is shown, figure 2 A fully mated PGA component 20 is illustrated. The receptacle 22 includes a base housing 26 , a cover 28 and a handle 30 . Cover 28 is slidably engaged with base housing 26 . The handle 30 is rotatable between open and closed positions and is used to manipulate the sliding movement of the cover 28 over the base housing 26 using a cam mechanism (not shown). figure 1 , the handle 30 is in the open position. figure 2 , the handle 30 is in the closed position. Before mating, the handle 30 is in the open position. Then, the first electronic package 24 is placed on the cover 28 such that the holes of the cover 28 accept the pins of the first electronic package 24 . With the handle 30 in the open position and the first electronics package 24 assembled on the cover 28 , the needles of the first electronics package 24 extend through the cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com