Method for reducing noise of equipments based on control of fan rotate speed

A noise reduction and fan speed technology, applied in pump control, mechanical equipment, non-variable pumps, etc., can solve the problems of fan speed control, unsatisfactory effect of equipment noise, and low accuracy of fan speed control. The effect of safe heat dissipation and reducing equipment noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

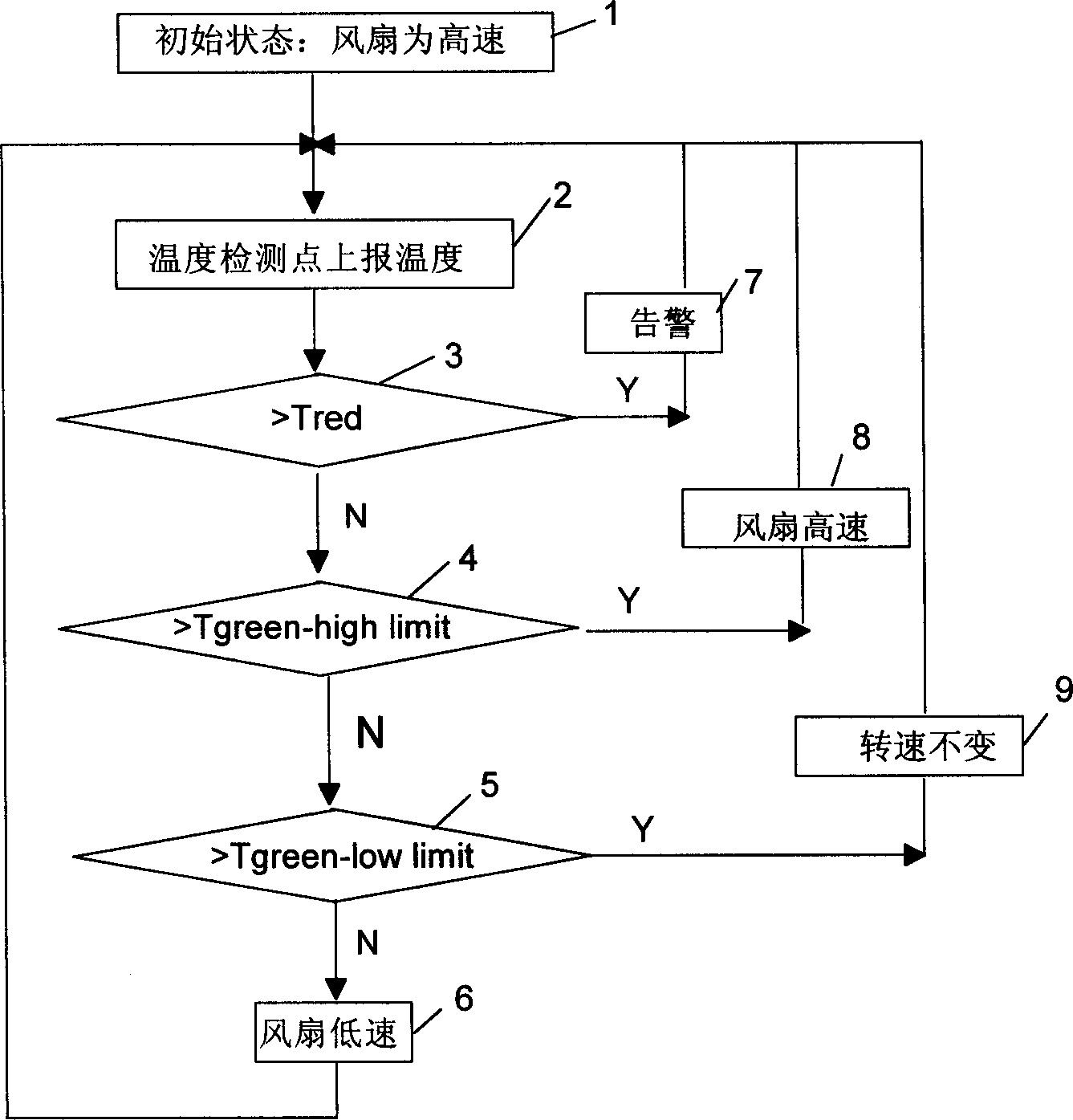

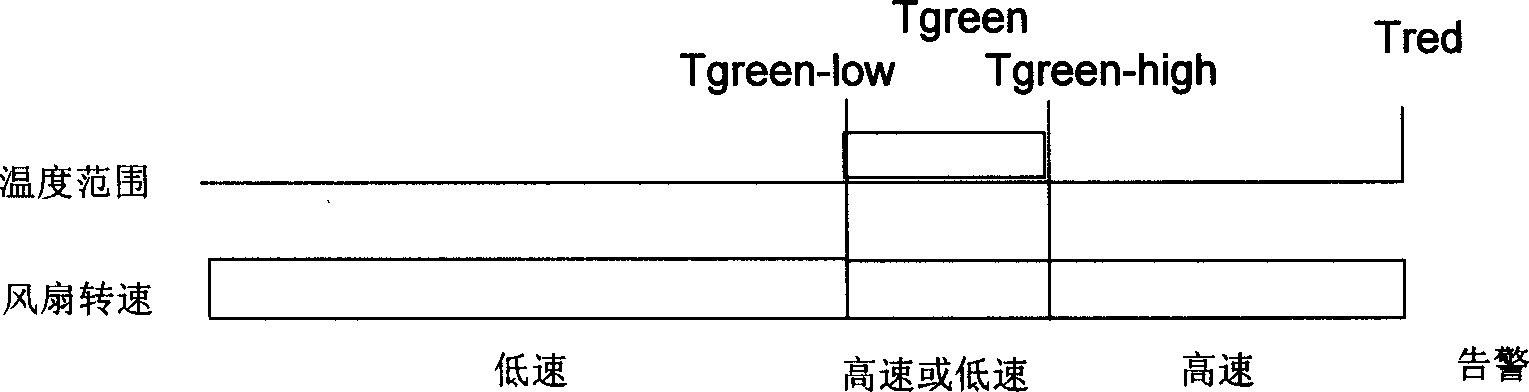

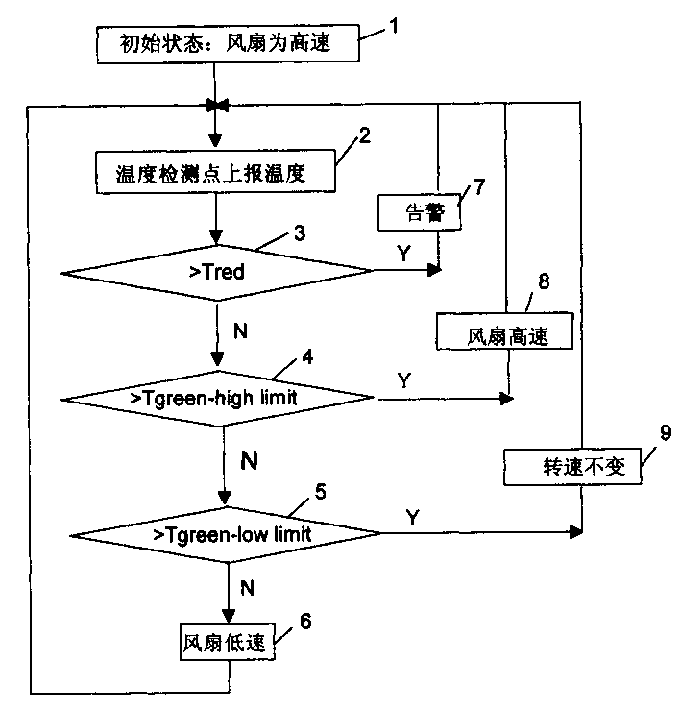

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0016] In the actual application of electronic and electrical equipment, the working environment of the equipment changes, so the fan of the equipment can adjust the speed while ensuring the effective heat dissipation of the equipment according to the change of the application environment of the equipment, thereby reducing the noise of the equipment. Lower fan speed can be reduced. Generally speaking, the speed, flow, and wind pressure of the fan change with the change of the fan voltage. Therefore, the fan speed, air flow, and wind pressure can be controlled by controlling the fan voltage, thereby controlling the noise of the device. In the process of removing heat from the equipment, the cooling air passes over the hot surface of the device or circuit board, and the two exchange heat. The temperature of the cold air is raised by heating, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com