Fluorescent resin board for bowling alley

A technology of fluorescent resin and bowling balls, applied in bowling balls, ski bindings, sports accessories, etc., can solve problems affecting performance improvement, affecting business, and increasing owner costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

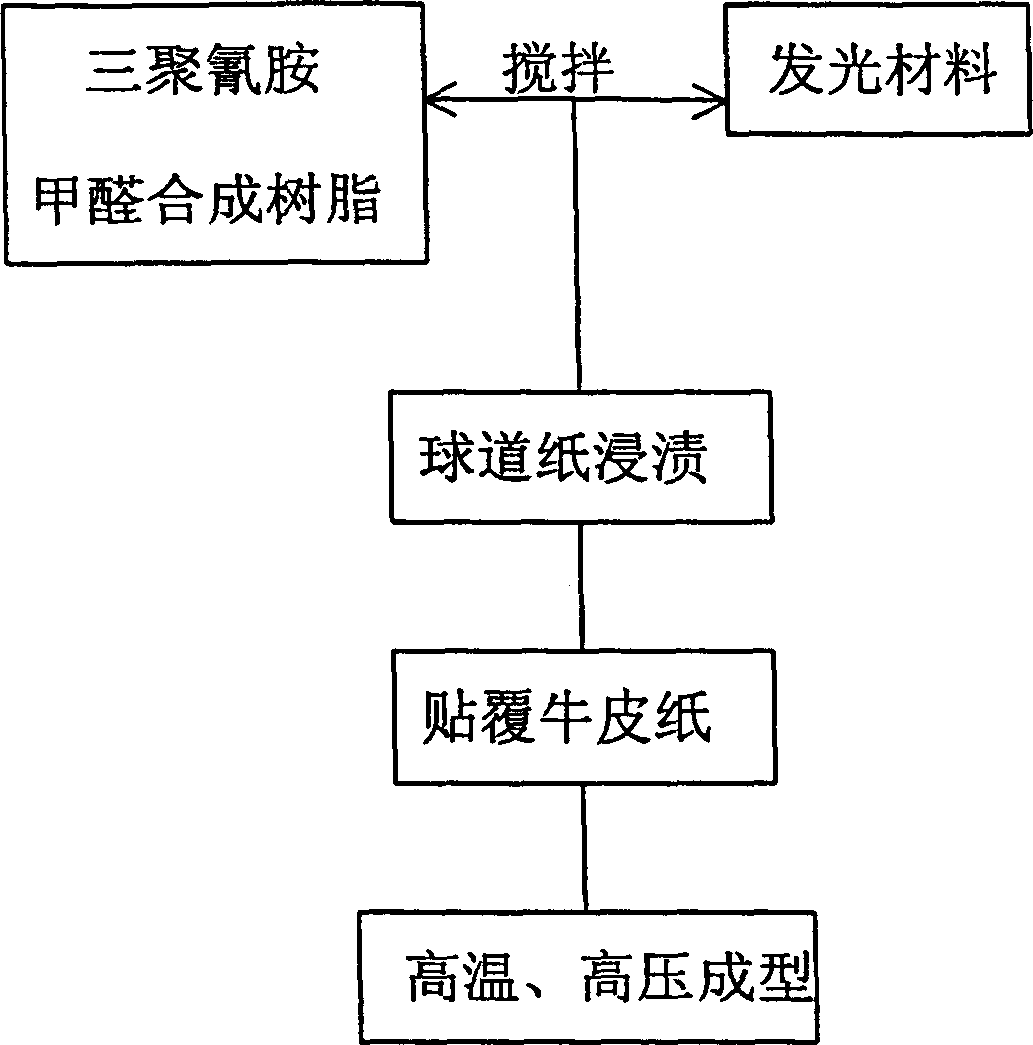

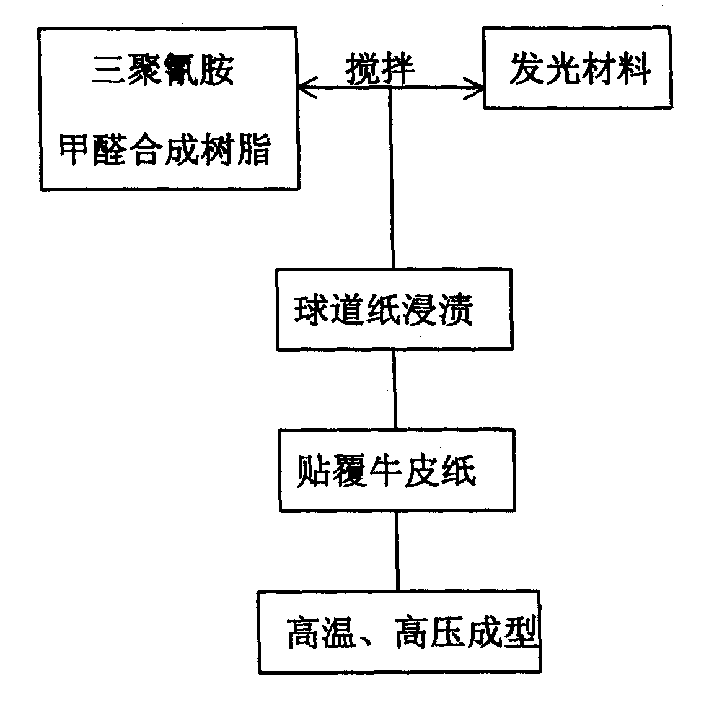

[0006] As shown in the figure, the production process of the present invention is realized in this way. First, a certain amount of fluorescent powder or luminous powder is added to the synthesis of melamine formaldehyde resin. The abrasive paper is soaked in melamine formaldehyde resin mixed with fluorescent powder or luminous powder, and after a period of impregnation, the fairway paper or wear-resistant paper has been soaked with melamine formaldehyde resin containing fluorescent powder or luminous powder. At this time, the lane mark is made into the lane paper, and the lane paper printed with the mark is pasted with the kraft paper and pressed to form by high-temperature pressure, and the fluorescent resin plate of the bowling lane is formed.

[0007] In summary, compared with the prior art, the product of the present invention has the advantage that luminescent materials are added at one time during the synthesis process of the product, and it becomes a permanent bowling la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com