In-situ trimming method for shaping abrasive wheel

A form grinding and grinding wheel correction technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, abrasive surface adjustment devices, etc., can solve the problem of affecting processing accuracy, difficulty in accurately grasping the time of grinding wheel dressing, long processing time, etc. problem, achieve the effect of improving grinding accuracy and reducing invalid processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

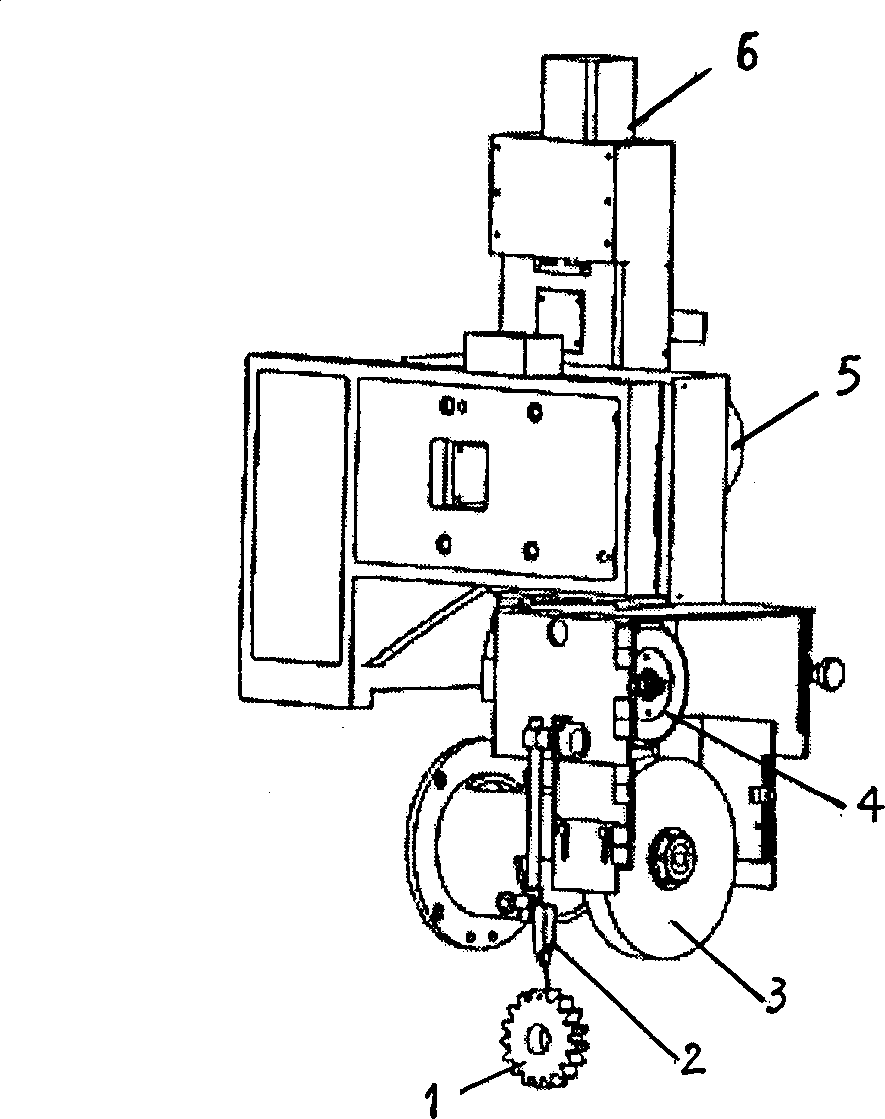

[0023] Depend on figure 1 As shown, the grinding wheel online dresser for grinding machine includes an online measuring head 2 for the processed curve shape of the workpiece and a measurement data processor. The measuring head 2 and the diamond roller 4 are connected to the X-axis servo motor 5 and the Z-axis servo motor 6 respectively. The measuring head adopts a lever-type inductive probe head.

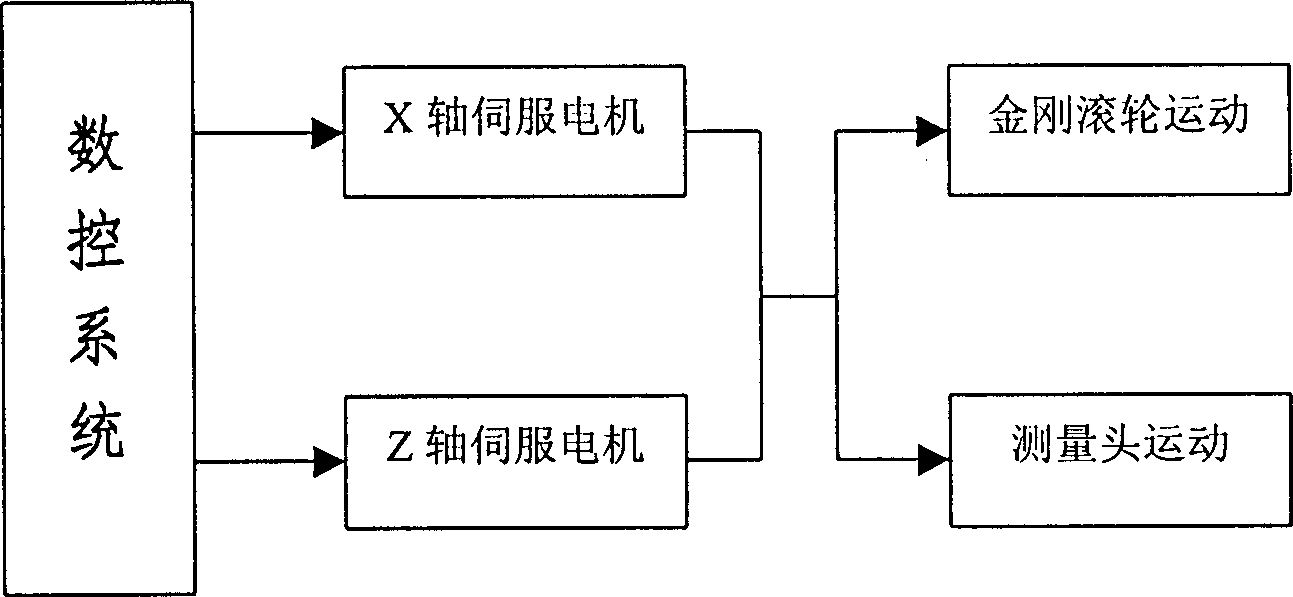

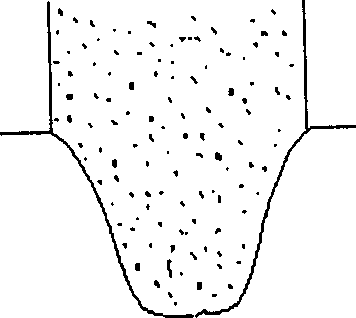

[0024] figure 1 The gear 1 in the figure is the processing workpiece, and the grinding wheel 3 is the forming grinding wheel on the grinding machine. When the grinding wheel needs to be trimmed, such as figure 2 As shown, the grinding wheel dresser controls the movement of the X-axis (longitudinal) servo motor and the Z-axis (up and down direction) servo motor through the numerical control system to realize the curved movement of the diamond roller, thereby completing the dressing of the curved surface of the grinding wheel. In order to measure the tooth shape error of the proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com