Active damper for washing machine

An active vibration reduction and washing machine technology, which is applied to washing devices, other washing machines, mechanical vibration control, etc., can solve the problems of complex devices, difficult vibration, and excessive size, and achieve the effect of suppressing fluctuations and reducing amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, provide a best example of the present invention:

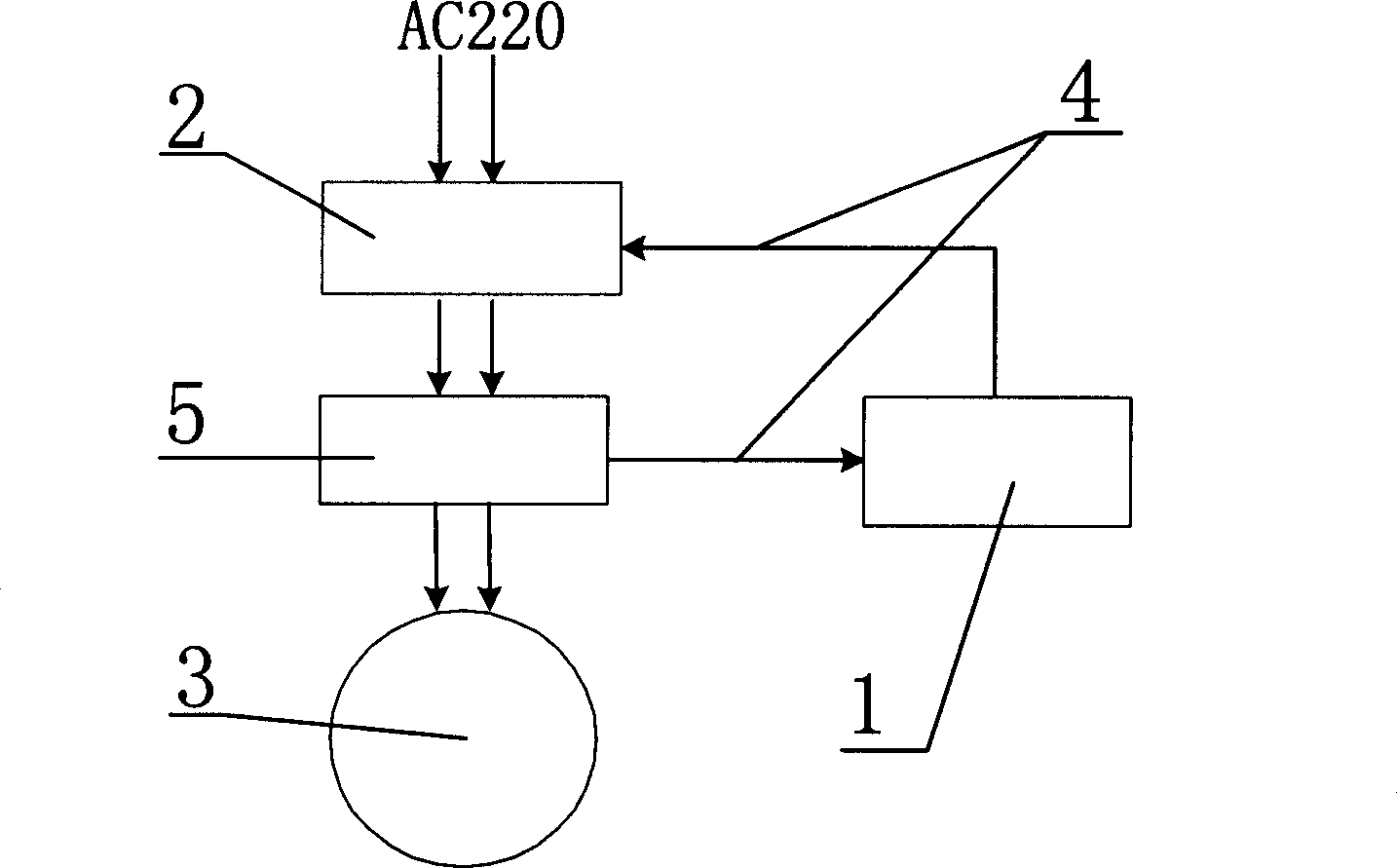

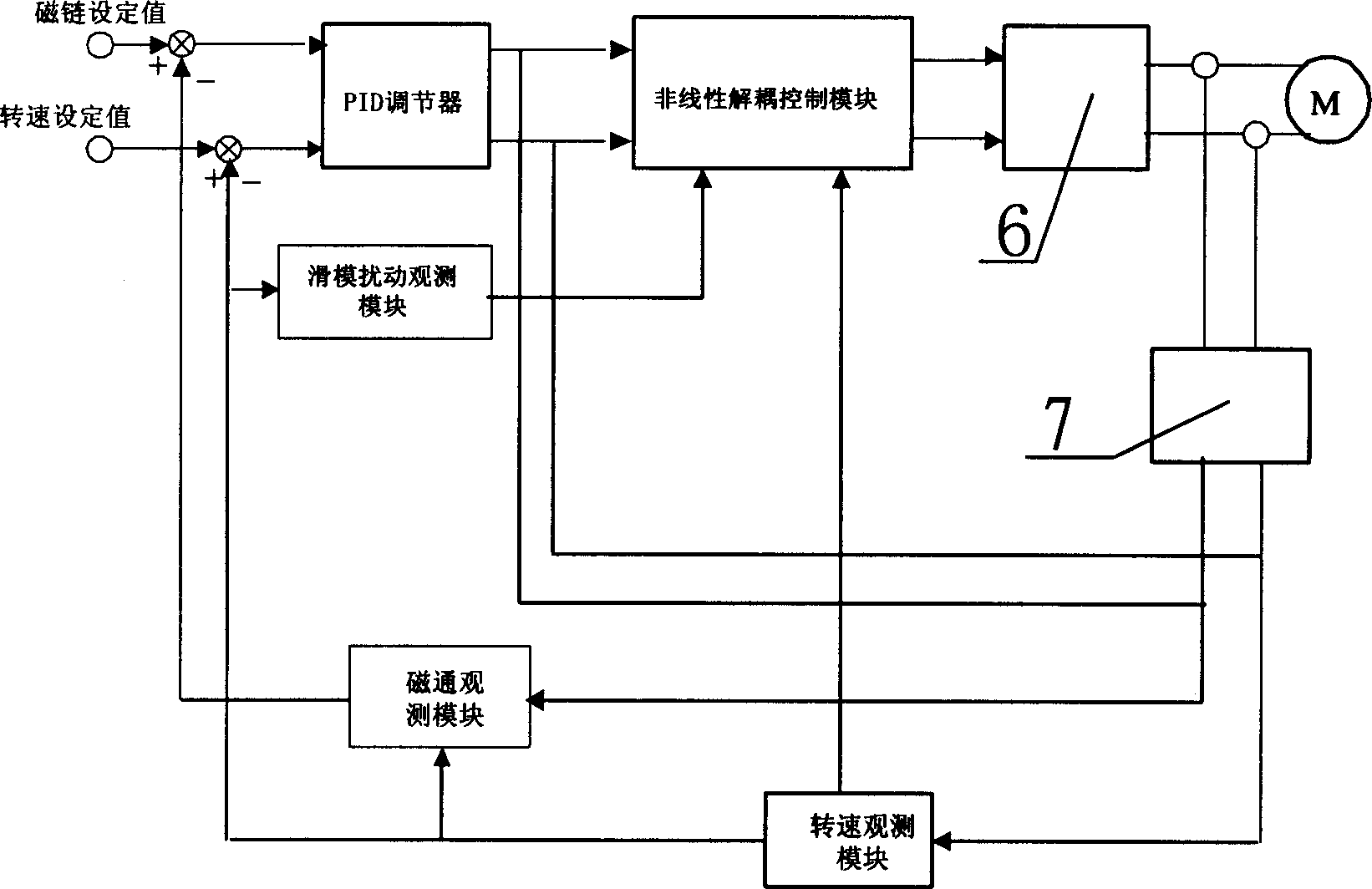

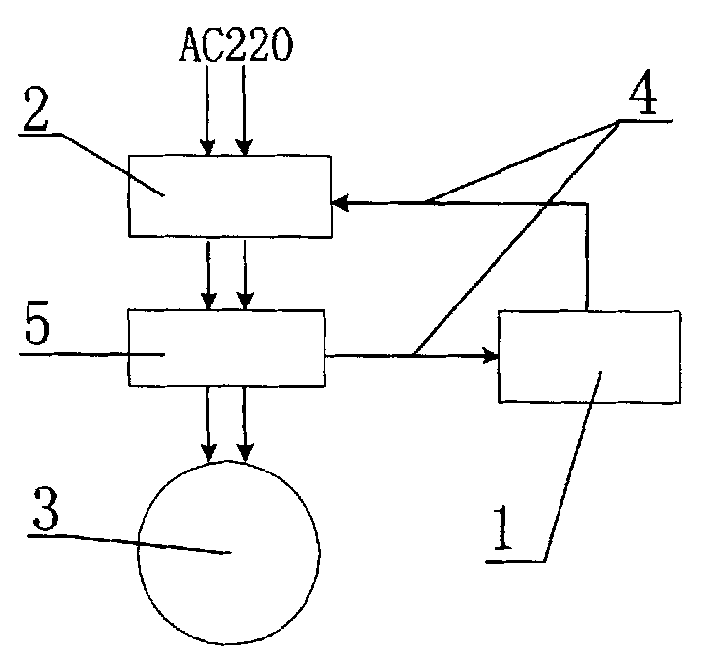

[0012] This example is implemented on the Xiaoya XQG50-166 drum washing machine. The active vibration reduction device consists of a controller 1, a power module 2, a washing machine motor 3, a connecting cable 4 and a current sensor 5. The power supply is connected to the input terminal of the power module 2, and its output terminal is connected to the input terminal of the washing machine motor after passing through the current sensor 5. The washing machine motor is a single-phase asynchronous AC motor (AC220V, 50Hz, 160W, the number of pole pairs is 2), and the controller 1 is respectively connected to the power module 2 and the current sensor 5 through the connecting cable 4.

[0013] The test speed of the washing machine motor is 1500r / min, and the eccentric torque is 2kgm.

[0014] Controller 1 is composed of microprocessor TMS320C240, program memory IS61C1024, inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com