Aperture size mesurer and measuring method

A measuring device and size technology, which is applied in the field of aperture measuring device and its aperture size measurement, can solve the problems of large reading error, poor accuracy, adverse effects of process production, etc., and achieve the effect of simple operation, good working environment and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Accompanying drawing is a specific embodiment of the present invention.

[0017] Below in conjunction with accompanying drawing, content of the present invention will be further described:

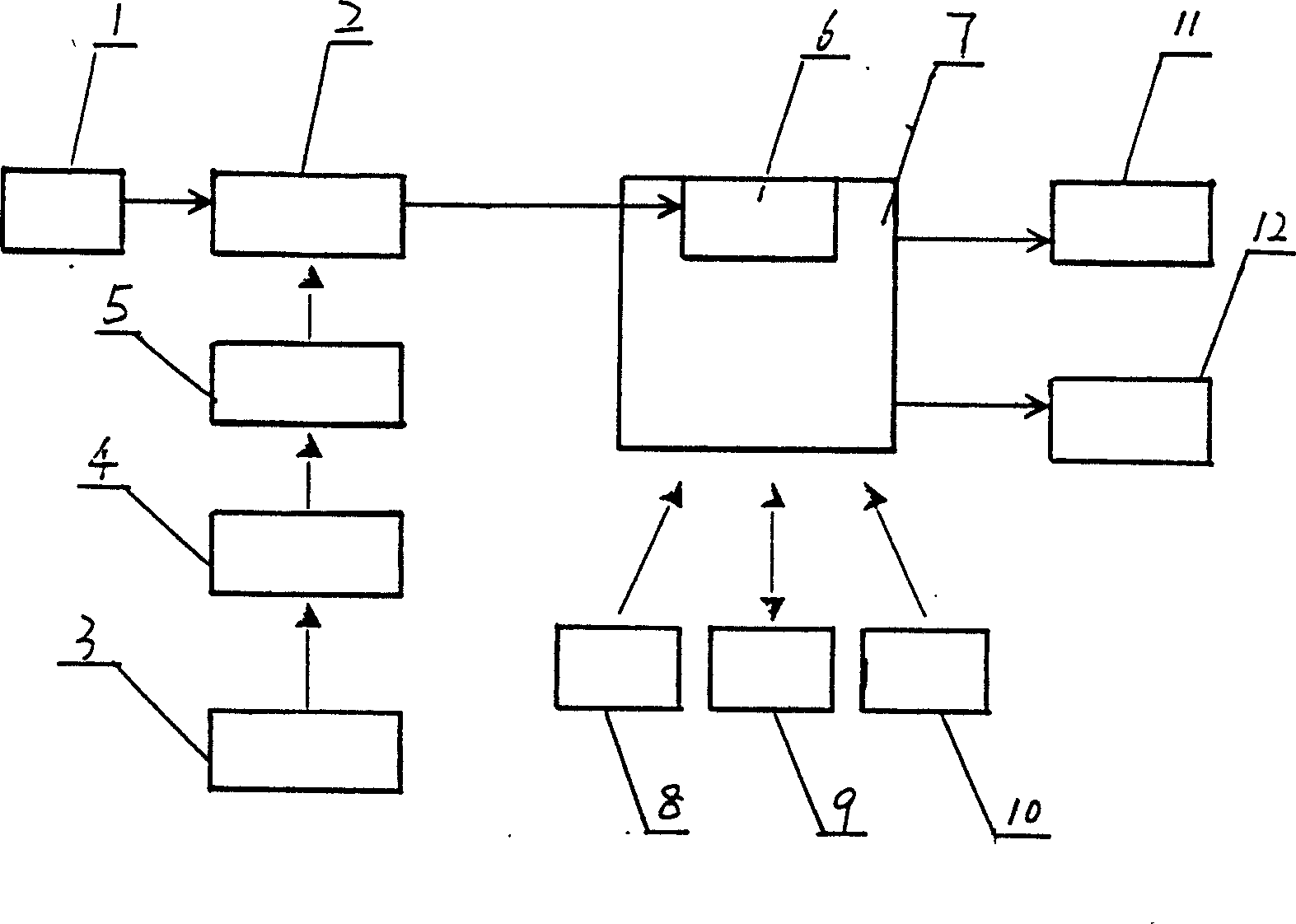

[0018] Referring to Fig. 1, it consists of hardware and software. It is characterized in that the hardware includes a power supply 1 connected to the optical coupling sensor 2, and the output end of the lighting power supply 3 is respectively connected to the shadow mask slot 4, the magnifying glass 5, and the optical coupling sensor 2 in turn. , the optical coupling sensor 2 is connected to the image card 6 and the industrial computer 7, and the industrial computer 7 is respectively connected with a keyboard 8, a hard disk 9, a mouse 10, a display 11, and a printer 12, and a computer software program is installed on the industrial computer 7.

[0019] A method for measuring aperture size, comprising the steps of:

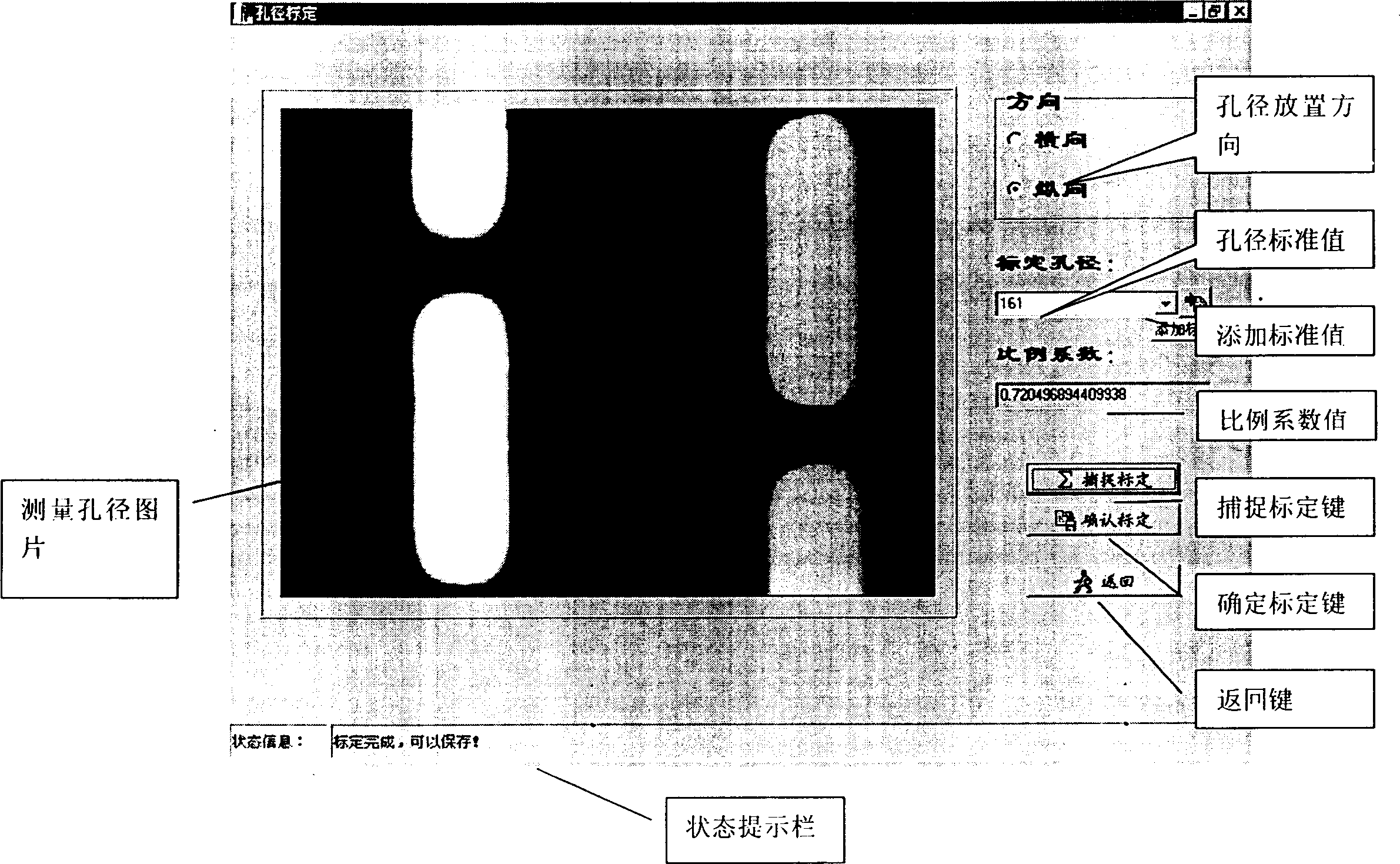

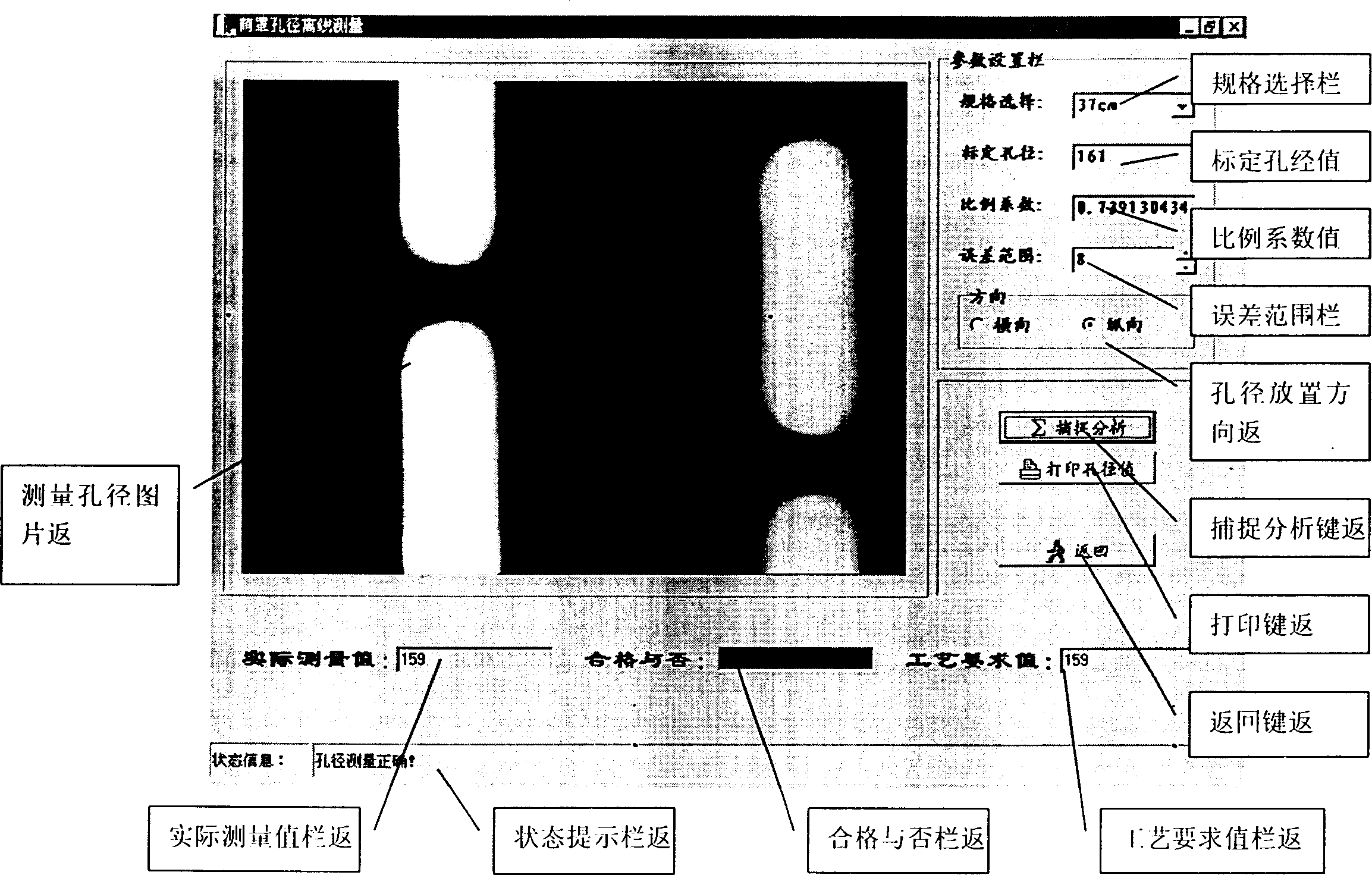

[0020] a. Calibration: Use the optical coupling sensor 2 to collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com