Flame-retardant reinforced polyamide resin composition

A technology of polyamide resin and composition, applied in the field of flame retardant polyamide resin composition, can solve the problems of deterioration of mechanical properties, easy breakage of molded products, and not necessarily satisfying electric and electronic parts and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

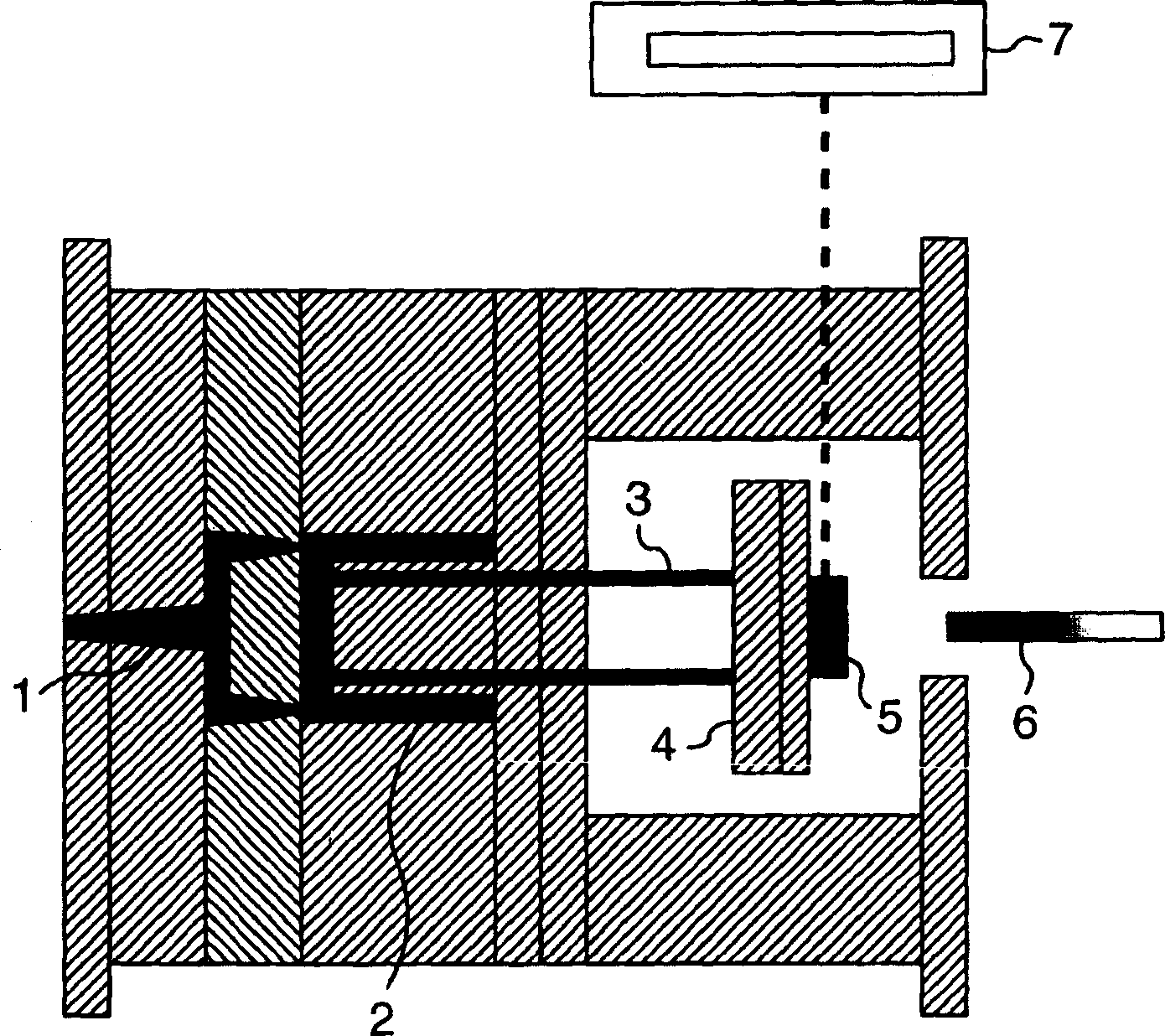

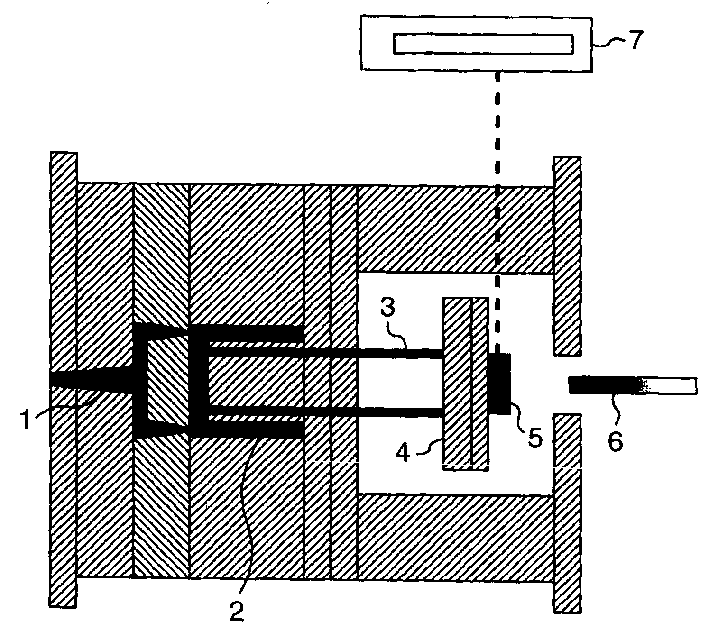

Image

Examples

Embodiment 1

[0123] In order to obtain a composition containing 49% by weight of polyamide resin (a-1), 26% by weight of flame retardant (b-1) and 25% by weight of glass fiber (c-1), polyamide (a-1) and The flame retardant (b-1) was fed from the top, and the glass fiber (c-1) was fed from the side, using a twin-screw extruder (TEM35 manufactured by Toshiba Machine Co., Ltd.) at a preset temperature in the barrel. Under the conditions of 260° C., screw speed of 200 rpm, and output of 30 kg / hour, the above materials were kneaded and extruded in the form of strands. After cooling, the strands were cut into pellets by a shear to obtain pellets of the polyamide resin composition. The obtained pellets were molded into test pieces, and various characteristics were determined by the above-mentioned measurement methods. The results are shown in Table 1. [Example 2]

Embodiment 2

[0124] Pellets were obtained in the same manner as in Example 1 except that (a-2) was used as the polyamide resin. The obtained pellets were processed into samples by molding, and various characteristics were determined by the above-mentioned measurement methods. The results are shown in Table 1. [Example 3]

Embodiment 3

[0125] Pellets were obtained in the same manner as in Example 1 except that (a-3) was used as the polyamide resin. The obtained pellets were processed into samples by molding, and various characteristics were determined by the above-mentioned measurement methods. The results are shown in Table 1. [Comparative Example 1]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap