Polymeric phosphorus-containing flame retardant with DOPO as lateral group and preparation method thereof

A phosphorus flame retardant, polymeric technology, applied in the field of polymeric phosphorus-containing flame retardants and its preparation, can solve the problems of large environmental pollution, leaching, poor compatibility of polymer matrix, etc., and achieve good flame retardant effect , Overcoming the effect of low thermal decomposition temperature and good expansion into charcoal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

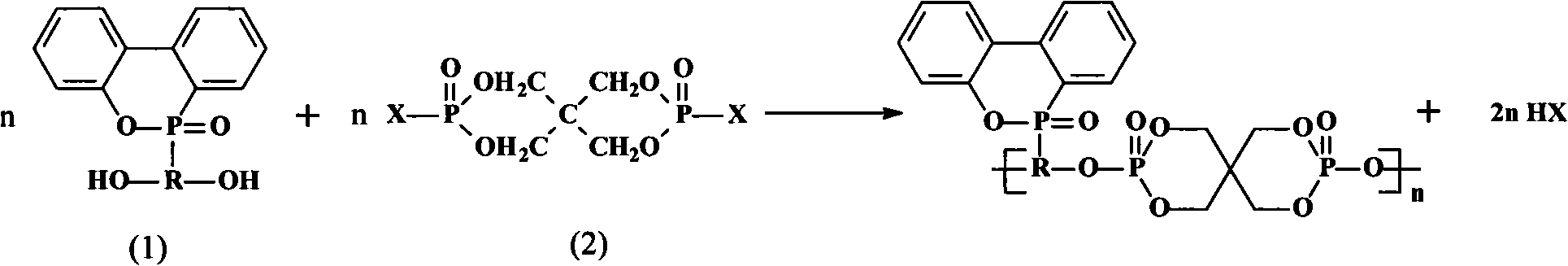

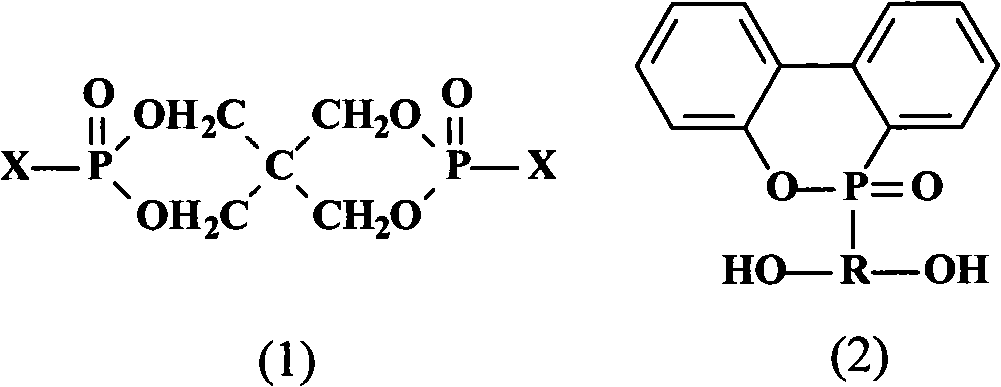

Method used

Image

Examples

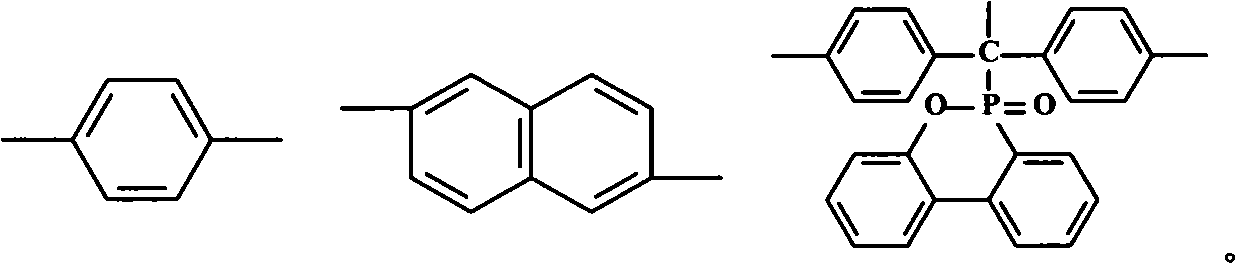

Embodiment 1

[0025] Add 29.7g (0.10mol) of pentaerythritol diphosphate diphosphoryl chloride, 150ml of anhydrous acetonitrile and 32.4g (0.10mol) of 9,10-dihydro -9-oxa-10-phosphaphenanthrene-10-oxide-hydroquinone, heat up to 80°C, react under continuous stirring until no HCl gas is released, cool to room temperature, remove the solvent under reduced pressure, and obtain pink Colored solid product. The yield is 95%, and the melting point is 220°C.

[0026] Infrared analysis is carried out to the obtained product, in pentaerythritol diphosphate diphosphoryl chloride, 583-541cm -1 The characteristic peak of P-Cl bond disappears at 929, 1189cm -1 P-O-Ph characteristic peak at 1442cm -1 P-Ph characteristic peak appears. It can be seen that the product of this example is a polymeric phosphorus-containing flame retardant with side groups of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide.

[0027] Take 6.6 grams of the polymeric phosphorus-containing flame retardant whose side group is ...

Embodiment 2

[0030] Add 29.7g (0.10mol) of pentaerythritol diphosphate diphosphoryl chloride, 150ml of anhydrous acetonitrile and 39.8g (0.10mol) of 9,10-dihydro -9-Oxa-10-phosphaphenanthrene-10-oxide-p-naphthalenediol, heated to 80°C, reacted under continuous stirring until no HCl gas was released, cooled to room temperature, and removed the solvent under reduced pressure to obtain a pink solid product. The yield was 92%, and the melting point was 235°C.

[0031] Infrared analysis is carried out to the obtained product, in pentaerythritol diphosphate diphosphoryl chloride, 583-541cm -1 The characteristic peak of P-Cl bond disappears at 929, 1189cm -1 P-O-Ph characteristic peak at 1442cm -1 P-Ph characteristic peak appears. It can be seen that the product of this example is a polymeric phosphorus-containing flame retardant with side groups of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide.

[0032] Take 6.6 grams of the polymeric phosphorus-containing flame retardant prepared in ...

Embodiment 3

[0035] Add 29.7g (0.10mol) of pentaerythritol diphosphate diphosphoryl chloride, 150ml of anhydrous acetonitrile and 39.8g (0.10mol) of 9,10-dihydro -9-Oxa-10-phosphaphenanthrene-10-oxide-bisphenol A, heated to 80°C, reacted under continuous stirring until no HCl gas was released, cooled to room temperature, and removed the solvent under reduced pressure to obtain a red solid product. The yield was 85%, and the melting point was 240°C.

[0036] Infrared analysis is carried out to the obtained product, in pentaerythritol diphosphate diphosphoryl chloride, 583-541cm -1 The characteristic peak of P-Cl bond disappears at 929, 1189cm -1 P-O-Ph characteristic peak at 1442cm -1 P-Ph characteristic peak appears. It can be seen that the product obtained in this example is a polymeric phosphorus-containing flame retardant with side groups of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide.

[0037] Get 6.6 grams of the polymeric phosphorus-containing flame retardant whose side g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal decomposition temperature | aaaaa | aaaaa |

| Maximum thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com