Adhesive material for touch screens

A technology for bonding materials and touch screens, applied in adhesives, thin material handling, instruments, etc., can solve the problems of insufficient dry thickness, easy foaming, low solid content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

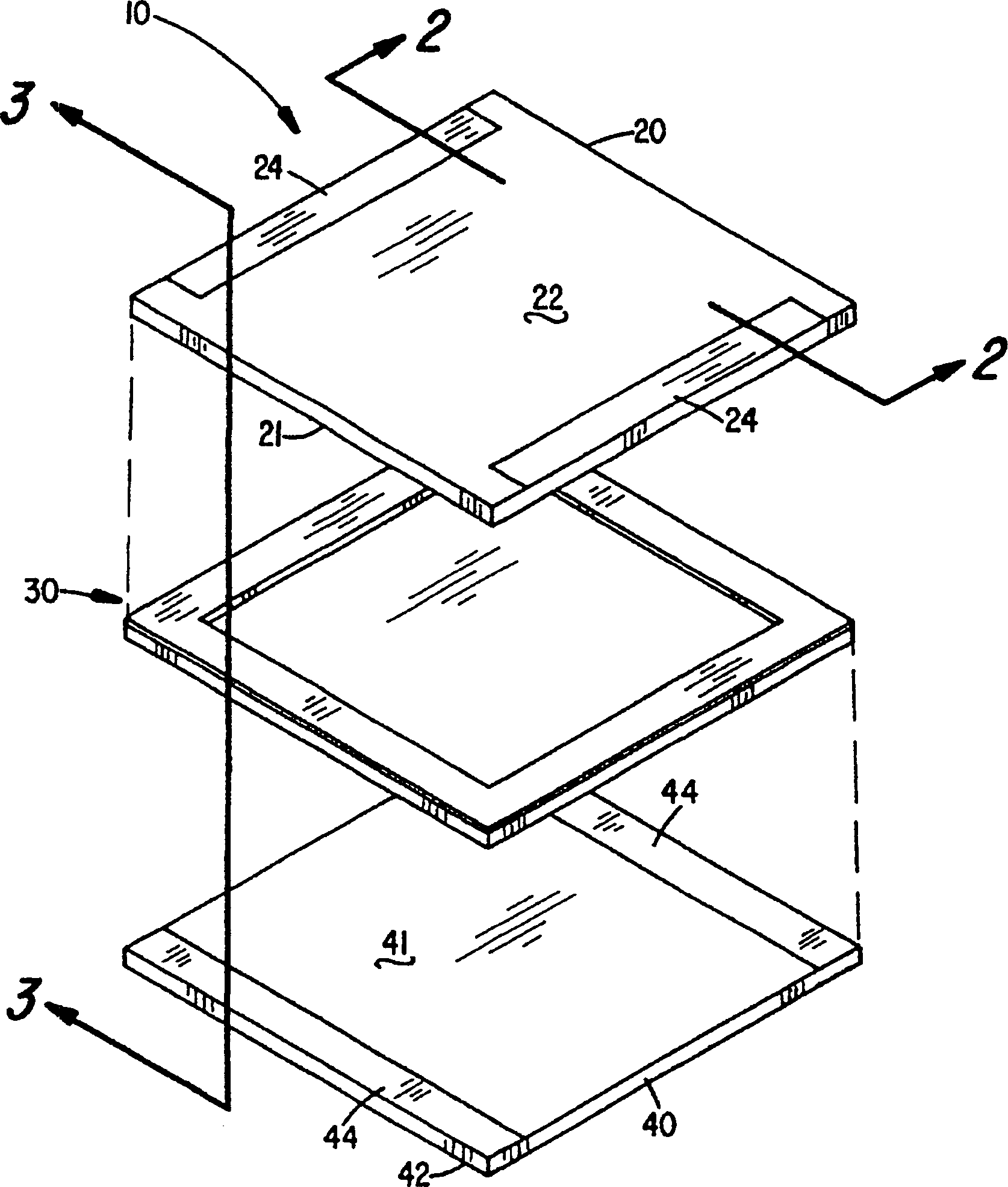

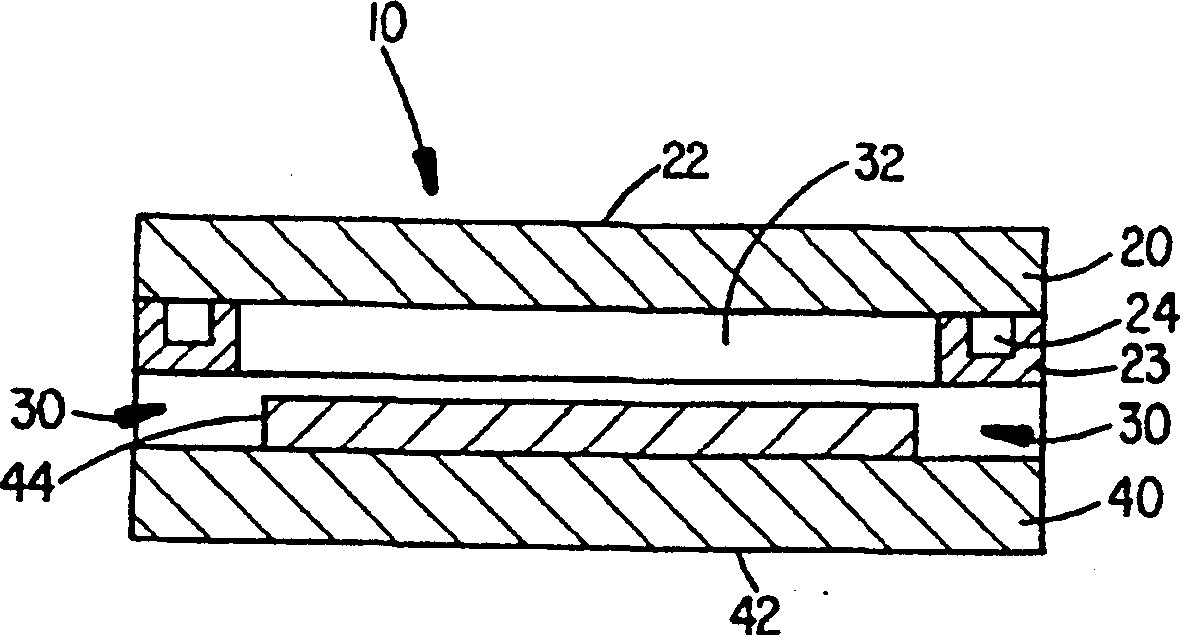

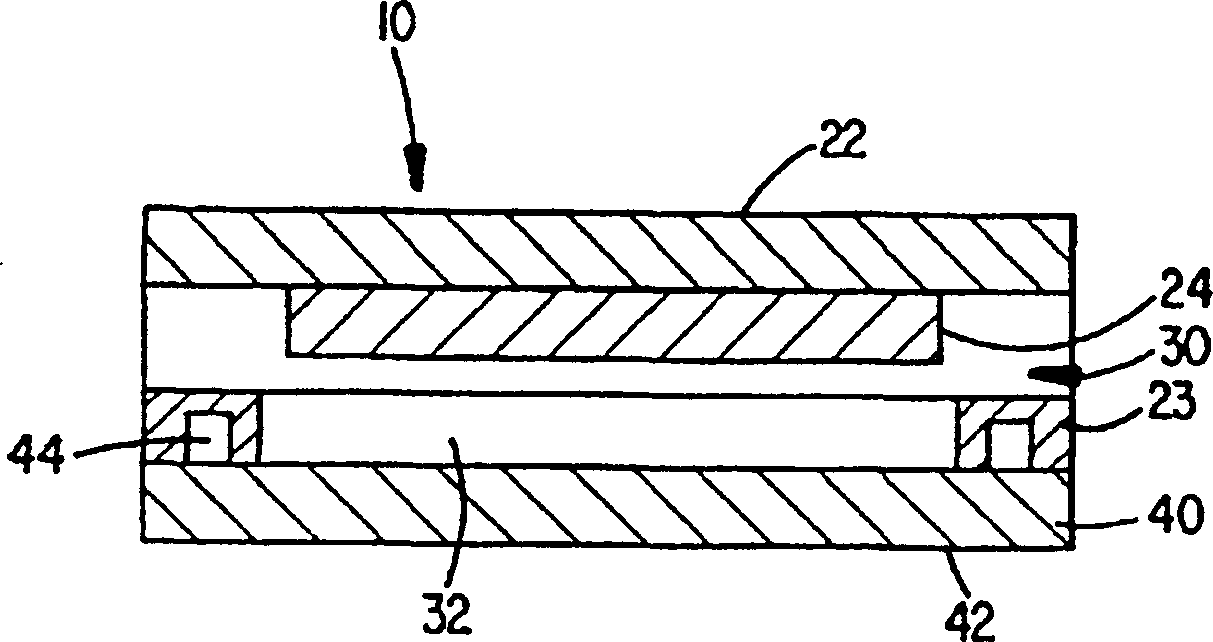

Image

Examples

Embodiment 1

[0050] Dow Corning 7502 Adhesive 100gm

[0051] Butyl CELLOSOLVE Acetate 50gm

[0052] GE SR1000 MQ resin (polytrimethylhydrogenated formaldehyde

[0053] silyl silicate) 7.5gm

[0054] Akzo Nobel Chemicals PERKADOX 50S

[0055] -ps-a, 2,4-dichlorobenzoyl peroxide 0.75gm

Embodiment 2

[0057] Dow Corning 7502 Adhesive 100gm

[0058] COMSOLVE 150 TM 50gm

[0059] GE SR1000 MQ resin (polytrimethylhydrogenated formaldehyde

[0060] silyl silicate) 7.5gm

[0061] Akzo Nobel Chemicals PERKADOX 50S

[0062] -ps-a, 2,4-dichlorobenzoyl peroxide 0.75gm

Embodiment 3

[0064] Dow Corning 7502 Adhesive 100gm

[0065] Butyl CELLOSOLVE Acetate 50gm

[0066] GE SR1000 MQ resin (polytrimethylhydrogenated formaldehyde

[0067] silyl silicate) 7.5gm

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap