Base-board conveying device

A technology for conveying devices and substrates, which is applied in the direction of support structure installation, rack/frame structure, electrical components, etc., and can solve the problems of low efficiency and difficult operation during operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

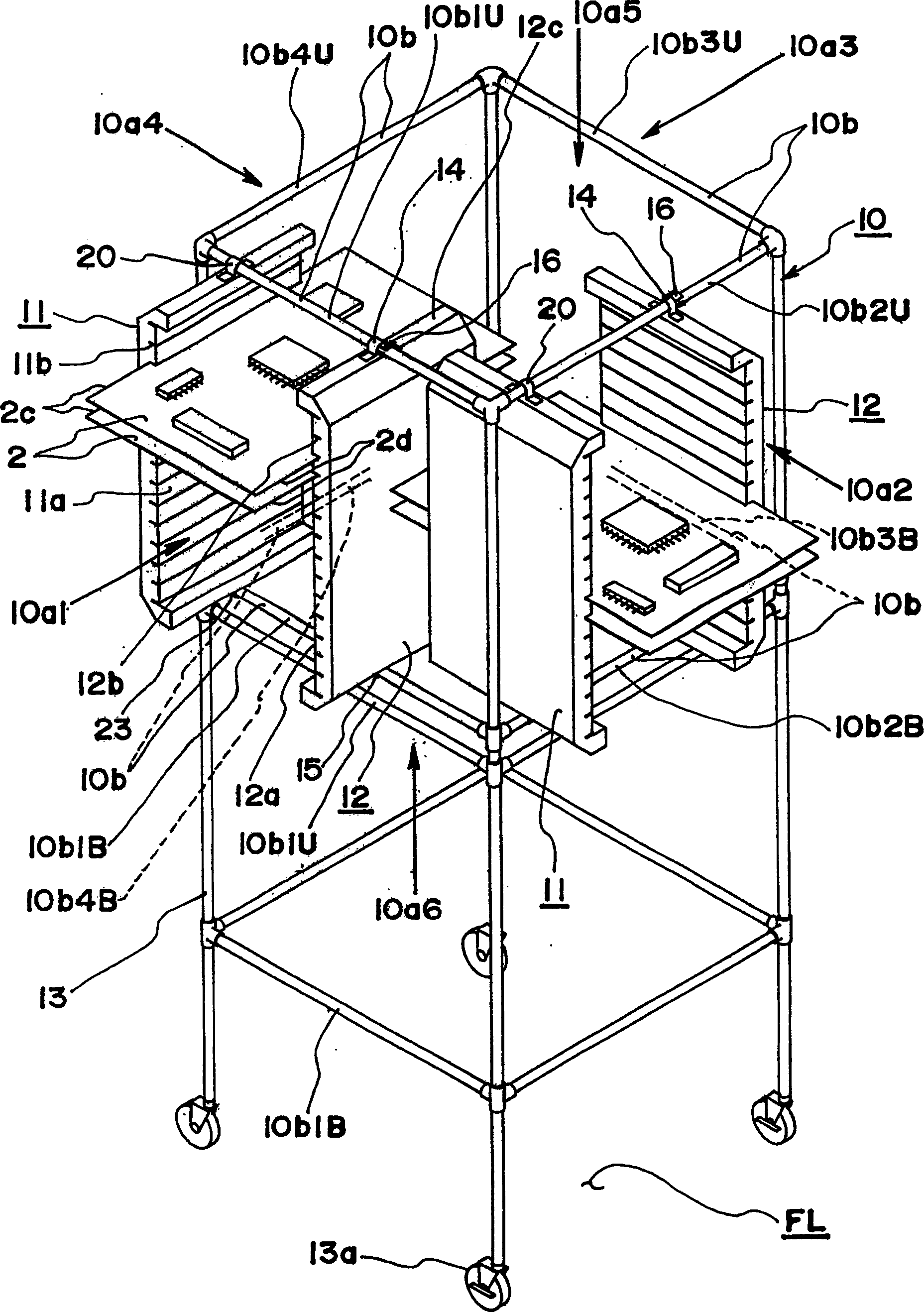

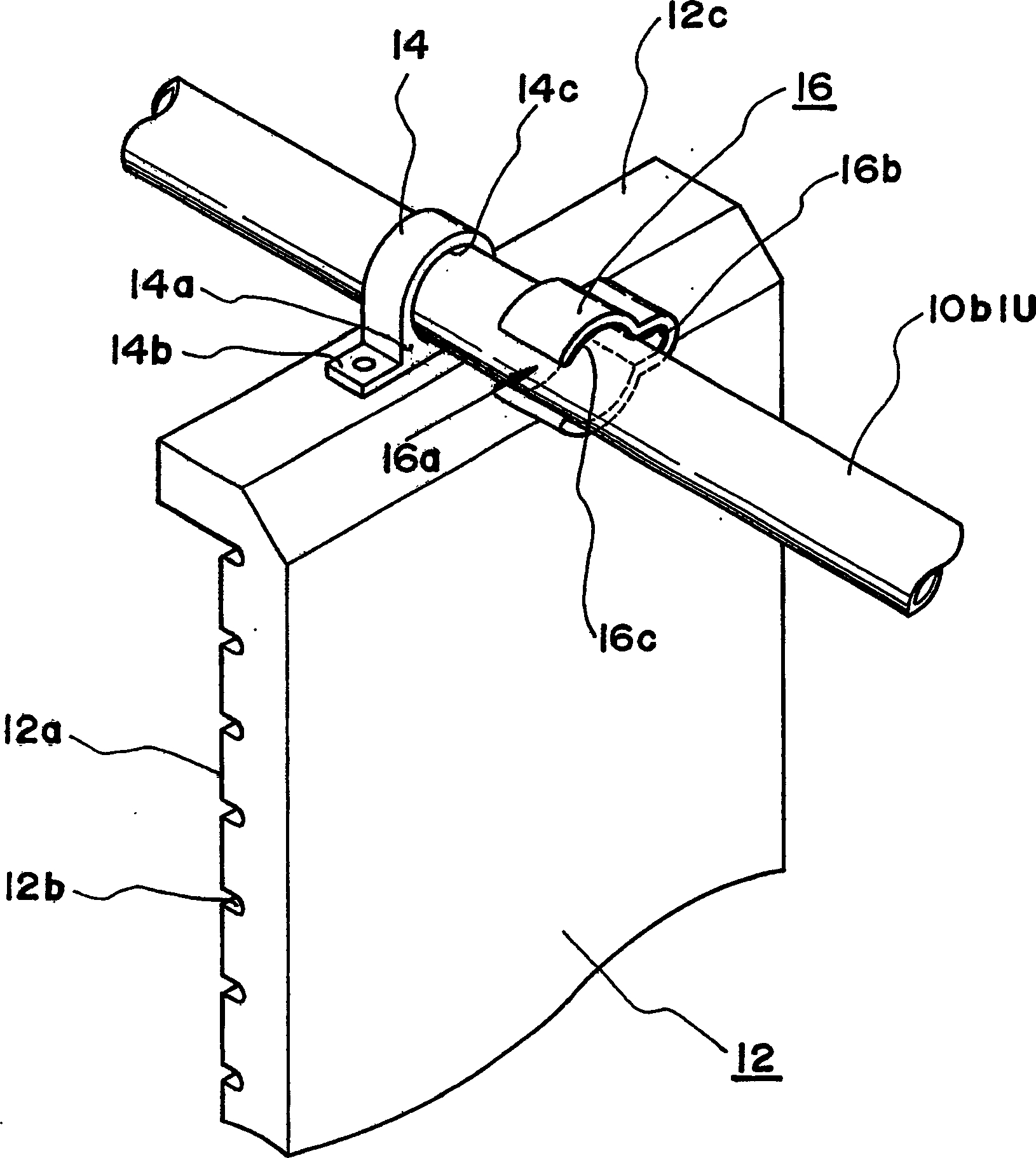

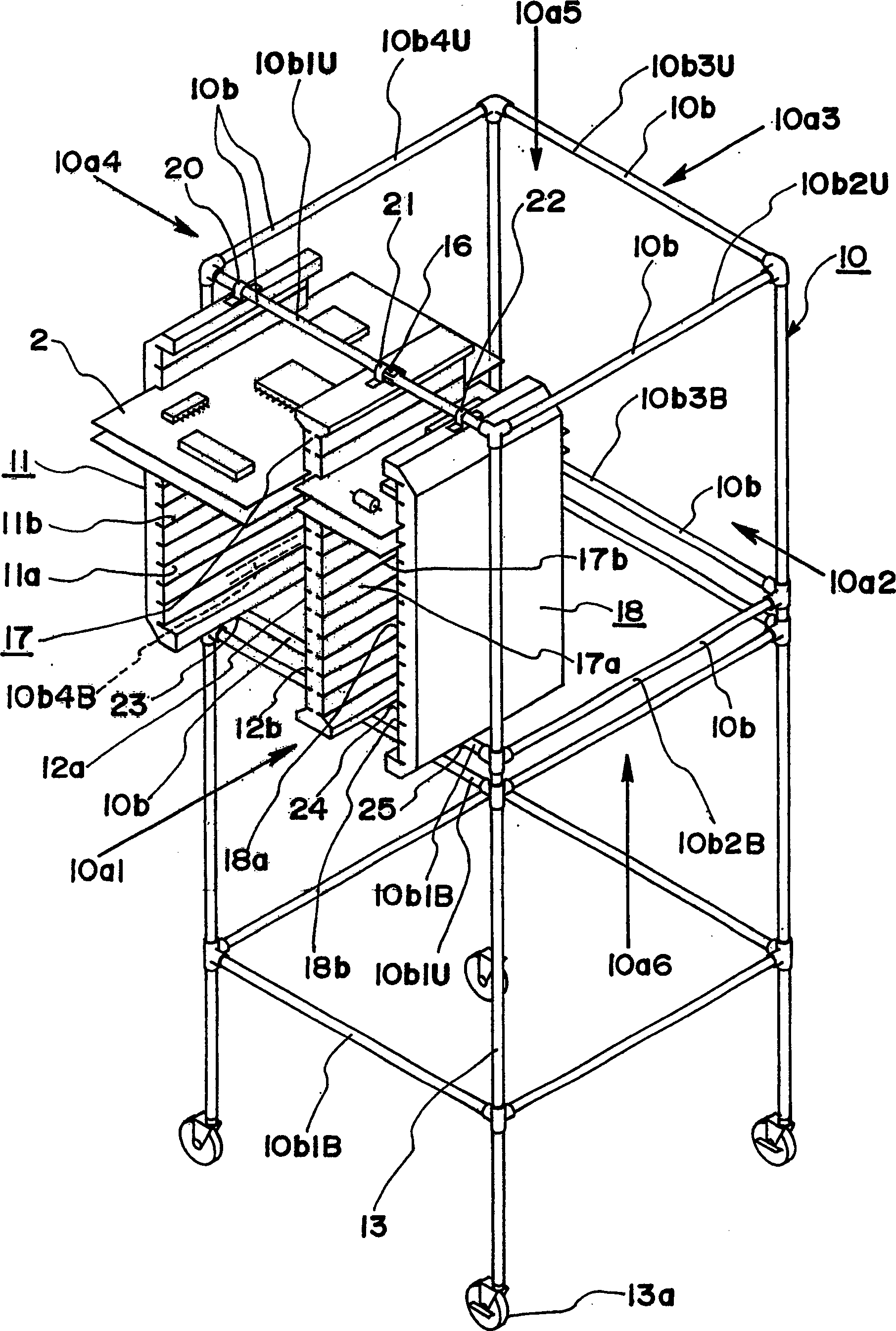

[0017] Refer below Figure 1 ~ Figure 4, to describe preferred embodiments for realizing the present invention. For example, in such a manner that six open faces 10a1, 10a2, 10a3, 10a4, 10a5, and 10a6 corresponding to the six faces of a dice, which are one of the hexahedrons, are formed, aluminum alloys extending along the ridgelines of the six faces are formed. Support rods 10b formed of plastic, resin pipes, etc. are assembled into the support frame 10. Among the above-mentioned support rods 10b, the support rods 10b extending along the upper ridgelines of the four adjacent open surfaces 10a, 10a2, 10a3, and 10a4 in the horizontal direction constitute the upper support rods 10b1U, 10b2U, 10b3U, and 10b4U. . Similarly, the lower support bars 10b1B, 10b2B, 10b3B, and 10b4B are constituted by the support bars 10b extending along the lower ridgelines of the four open surfaces 10a1, 10a2, 10a3, and 10a4 among the above-mentioned support bars 10b. In a vertical posture bridging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com