Method for preparing phosphoric acid rare earth monocrystalline nano-thread

A single crystal nanometer, rare earth phosphate technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., to achieve the effect of strong applicability, high crystallinity, and pure phase state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 Lanthanum phosphate nanowire

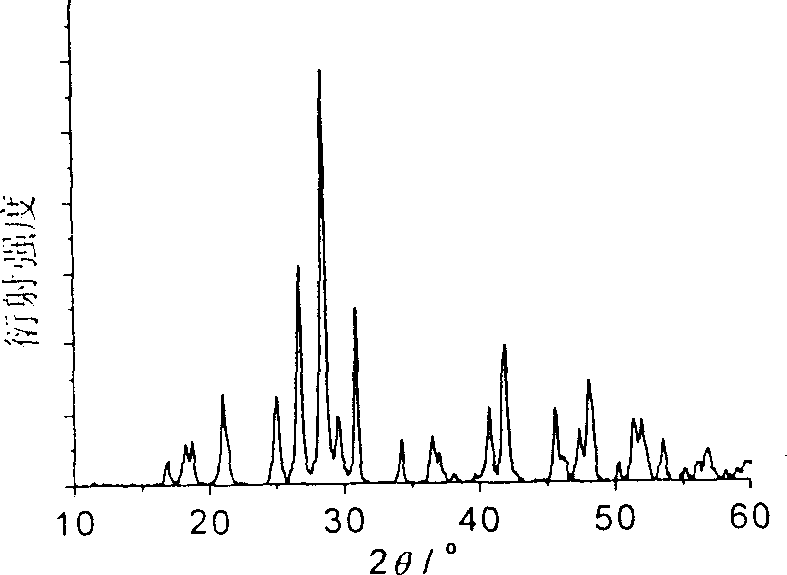

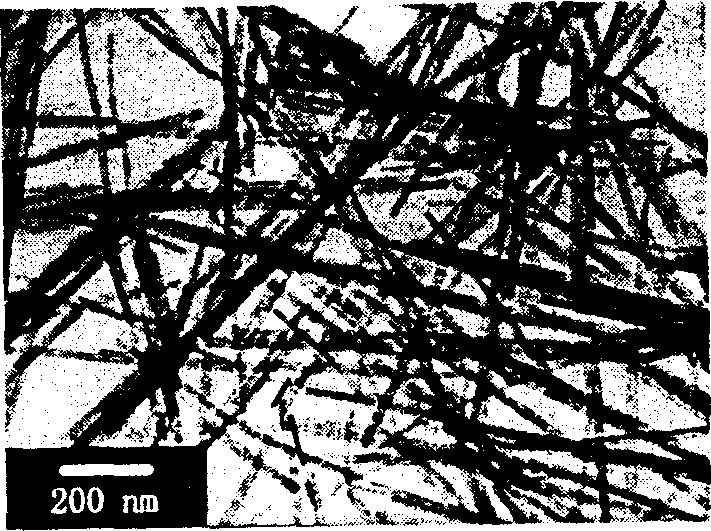

[0025] Add 0.0022 moles of phosphoric acid to 40 milliliters of 0.05 moles of lanthanum nitrate solution. After mixing evenly, the pH is 0.8. The cup-shaped container made of polytetrafluoroethylene containing the above solution is placed in a closed pressure-resistant stainless steel reaction kettle. And react under corresponding autogenous pressure for 17 hours. Then, cool to room temperature, filter, wash and dry at 60°C to obtain a white powder. The product was identified by powder X-ray diffraction as monoclinic lanthanum phosphate ( figure 1 ); Observing this product with a transmission electron microscope is a nanowire, with a length of 1-3 microns and a width of 20-50 nanometers ( figure 2 ). Electron diffraction proved that the lanthanum phosphate nanowires were single crystals.

Embodiment 2

[0026] Embodiment 2 Ceric phosphate rice noodles

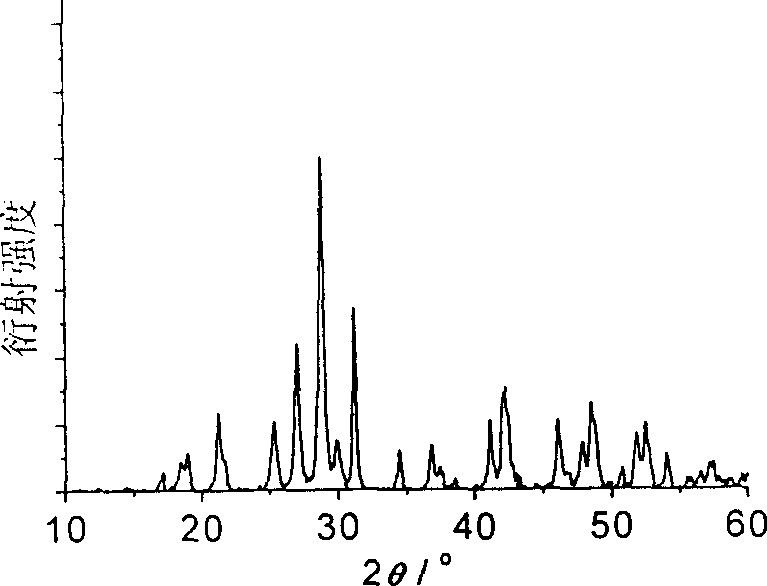

[0027] Add 0.0022 moles of phosphoric acid to 40 milliliters of 0.05 moles of cerous nitrate solution, and after mixing uniformly, the pH is 0.8, and the cup-shaped container made of polytetrafluoroethylene material that fills the above solution is placed in a closed pressure-resistant stainless steel reaction kettle, at 220 ℃ under corresponding autogenous pressure to react for 17 hours. Then, cool to room temperature, filter, wash and dry at 60°C to obtain a white powder. The product was identified by powder X-ray diffraction as monoclinic cerium phosphate ( image 3 ); Observing with transmission electron microscope that this product is a nanowire, the length is 2-5 microns, and the width is 20-100 nanometers ( Figure 4 ). Electron diffraction proves that the cerium phosphate nanowires are single crystals.

Embodiment 3

[0028] Embodiment 3 europium phosphate nanowire

[0029] Add 0.0022 moles of ammonium dihydrogen phosphate to 40 milliliters of 0.05 moles of cerous nitrate solution, and after mixing evenly, the pH is 1. Place the cup-shaped container made of polytetrafluoroethylene containing the above solution in a closed pressure-resistant stainless steel reaction kettle , reacted at 240°C and corresponding autogenous pressure for 24 hours. Then, cool to room temperature, filter, wash and dry at 60°C to obtain a white powder. The product was identified by powder X-ray diffraction as monoclinic europium phosphate ( Figure 5 ); Observing with a transmission electron microscope that the product is a nanowire, the length is 3-10 microns, and the width is 50-200 nanometers ( Image 6 ). Electron diffraction proves that the europium phosphate nanowires are single crystals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap