Laminated iron core fixing structure of reciprocating movement motor

A technology of laminated iron core and reciprocating motion, applied in the direction of magnetic circuit shape/style/structure, electrical components, electromechanical devices, etc., can solve the problems of incorrect air cover size, hindering the movement of the rotor 40, and unable to combine the fixed ring 50, etc. , to achieve the effect of easy and simple fixing process, accurate assembly size and prevention of mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of the present invention will be described in detail as follows.

[0044] 100. Coil 200. Coil barrel

[0045] 300. Terminal part 400. First laminated iron core

[0046] 500. Second laminated iron core 600. Rotor

[0047] 610. Permanent magnet 620. Magnet holder

[0048] 700. Fixed ring 710. Inflow part

[0049] 720. Support part P. Silicon steel sheet

[0050] A. Insertion groove a. Square shape groove

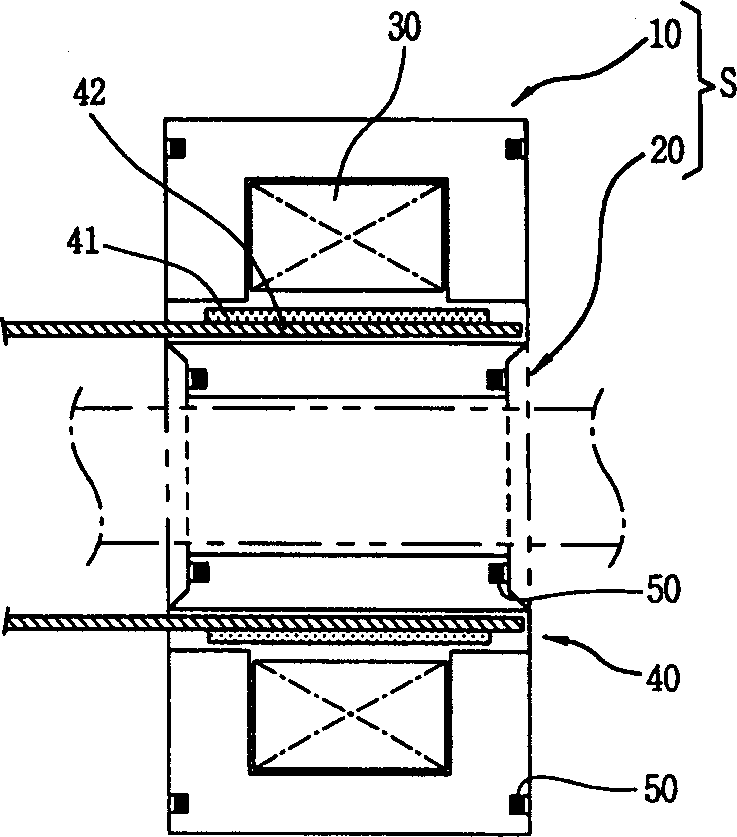

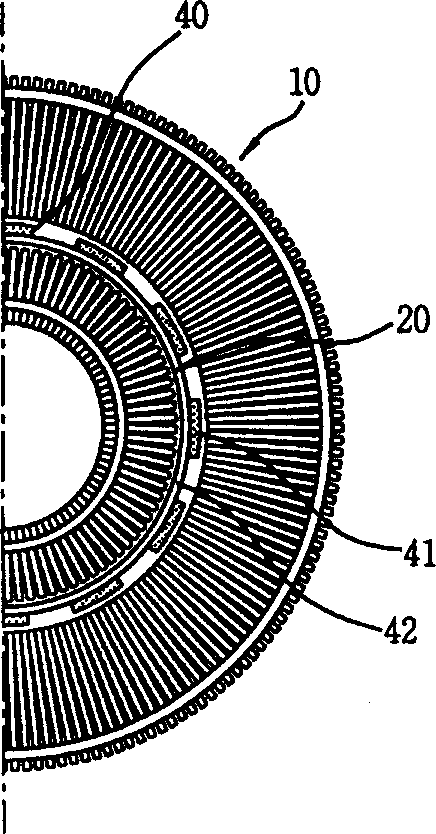

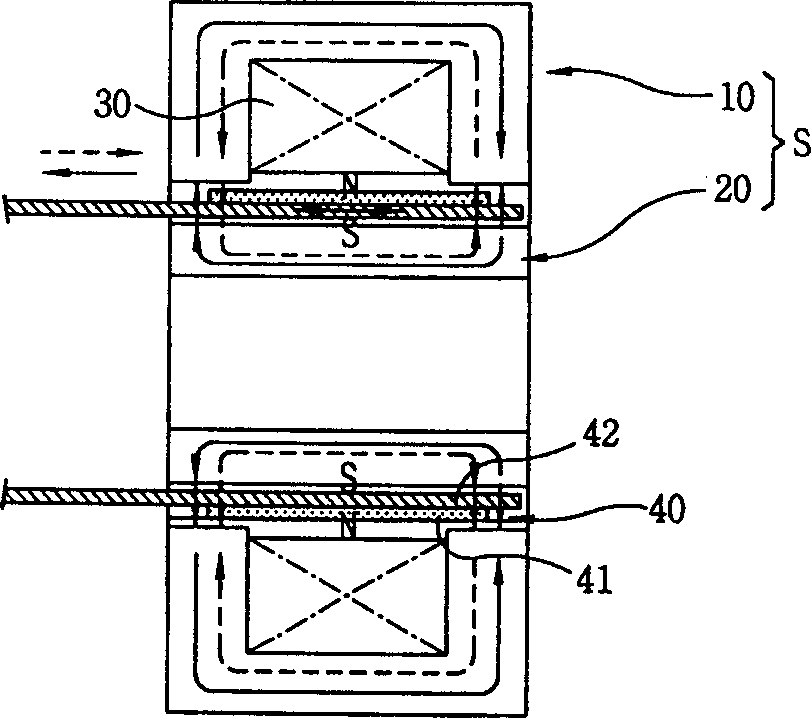

[0051] see Figure 5 , Image 6 As shown, the laminated iron core fixing structure of the reciprocating motor of the present invention consists of the following structures: a coil barrel 200 , a terminal portion 300 , a first laminated iron core 400 and a second laminated iron core 500 . The coil barrel 200 is wound with the coil 100 inside the ring; the terminal part 300 is arranged on one side of the coil barrel 200, and tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com