Side plate fixing structure and integrated window air conditioner

A technology of fixing structure and side plate, applied in heating mode, household heating, heating and ventilation hood/cover, etc., can solve the problems such as oxidation and blackening of the bell mouth, deformation and blackening of the side plate, and the side plate cannot be too wide, etc. To reduce difficulty, facilitate assembly, and improve assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

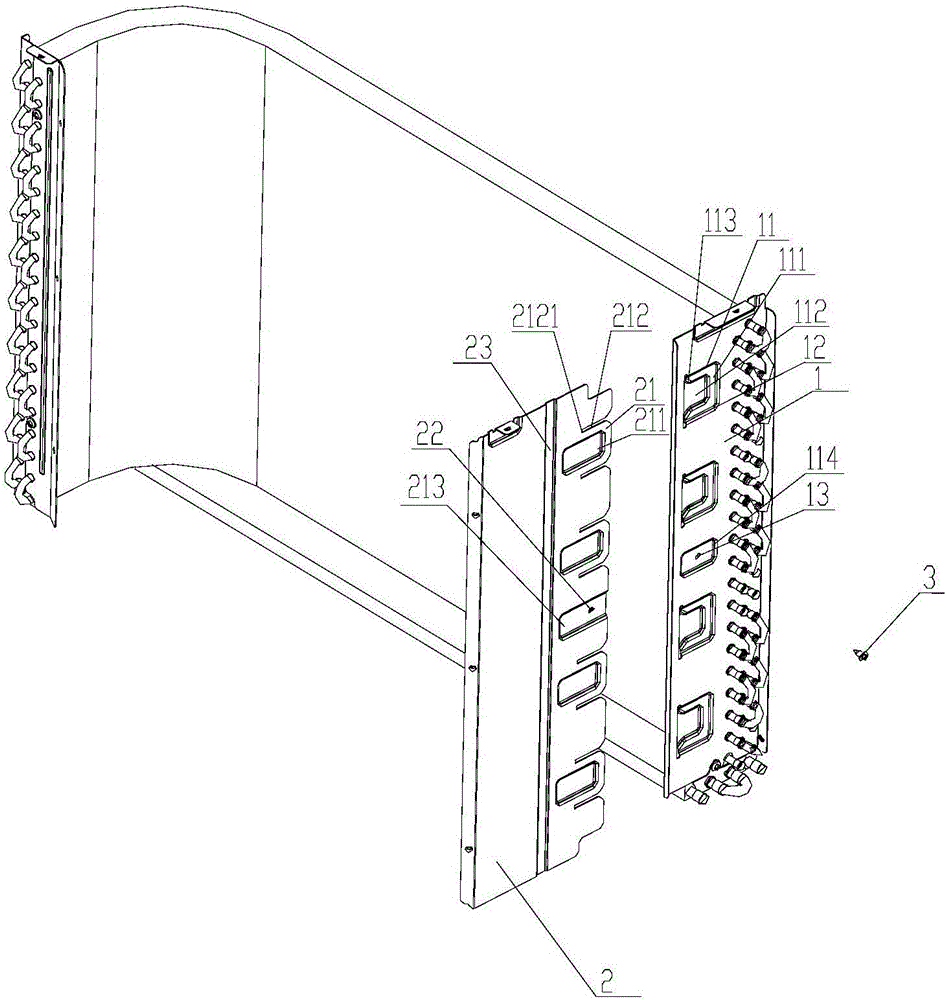

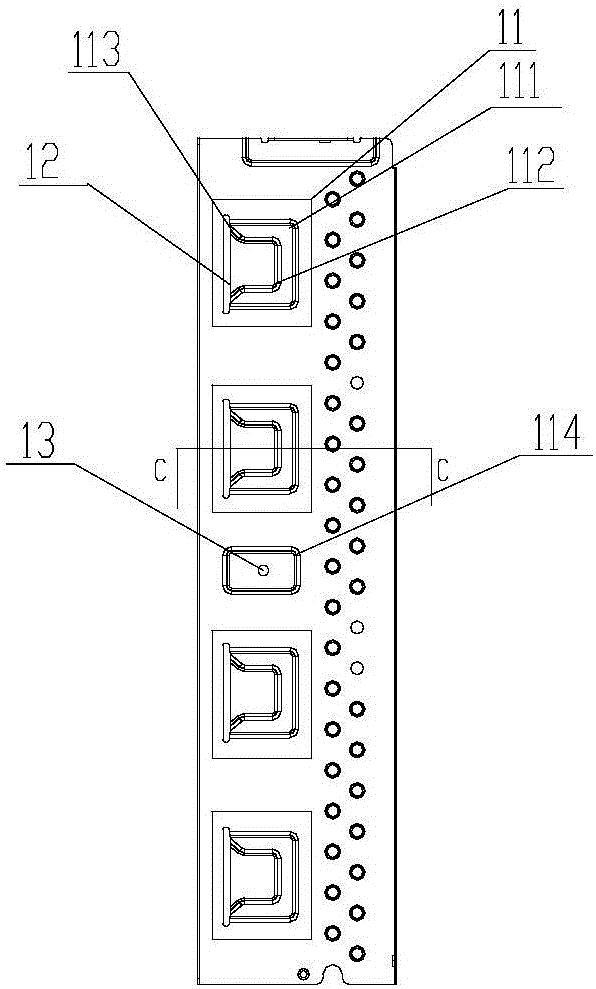

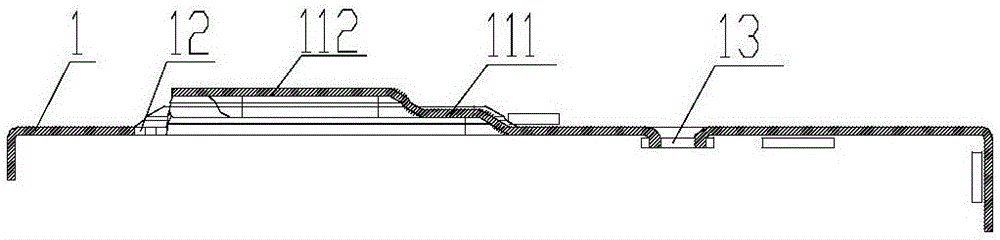

[0030] The invention provides a side plate fixing structure, such as Figure 1-7 As shown, it includes: a first side plate 1 and a second side plate 2, the first side plate 1 is provided with at least two first convex structures 11, and the outer side of each of the first convex structures 11 is also A limit opening 12 is provided, and at least two second convex structures 21 matching the first convex structure 11 are opened on the second side plate 2, and the upper and lower sides of the second convex structures 21 are Guide grooves 212 are provided respectively, and the second convex structure 21 is snapped into the first convex structure 11 from the limiting opening 12 through the guide grooves 212 .

[0031] The first side plate 1 and the second side plate 2 are fixedly connected by the matching first convex structure 11 and the second convex structure 21, which reduces the use of screws and eases the difficulty of assembly, while maintaining the first side plate 1 The co...

Embodiment 2

[0043] Also provided is an integral window machine, including an outdoor heat exchanger, on which the side plate fixing structure is arranged.

[0044] To sum up, the first side plate 1 and the second side plate 2 are fixedly connected through the matched first convex structure 11 and the second convex structure 21, which reduces the use of screws and eases the difficulty of assembly, while maintaining The first side plate 1 and the second side plate 2 are reliably connected; the structure of the guide groove 212 and the limit opening 12 is accurate in positioning, convenient in assembly, accurate in assembly size, not easily deformed, and convenient in disassembly and maintenance. The setting of the guide structure 113 facilitates the matched installation of the third convex hull 211 and the second convex hull 112, so as to avoid collision damage between the third convex hull 211 and the second convex hull 112 during assembly due to differences in pushing directions, The asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com