Signal and power supply integrated mode switching structure and method thereof

A mode switching and signal technology, applied in the field of signal switching, can solve the problems of poor contact, large deviation of assembly size, occupying space, etc., and achieve the effect of accurate switching time demarcation point, accurate assembly size and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In the present invention, the function option signal and the power switch signal are combined to act on the same switch, so that one switch can simultaneously provide the dual functions of the power switch and the function option switch.

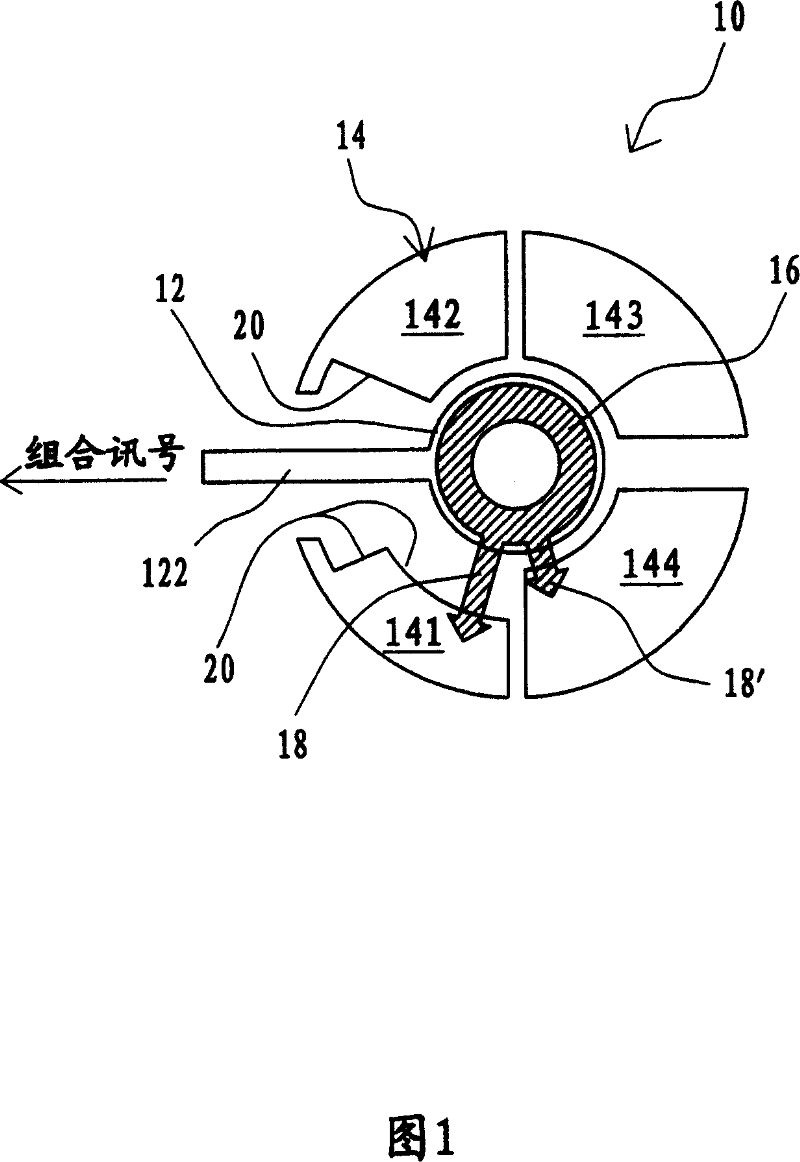

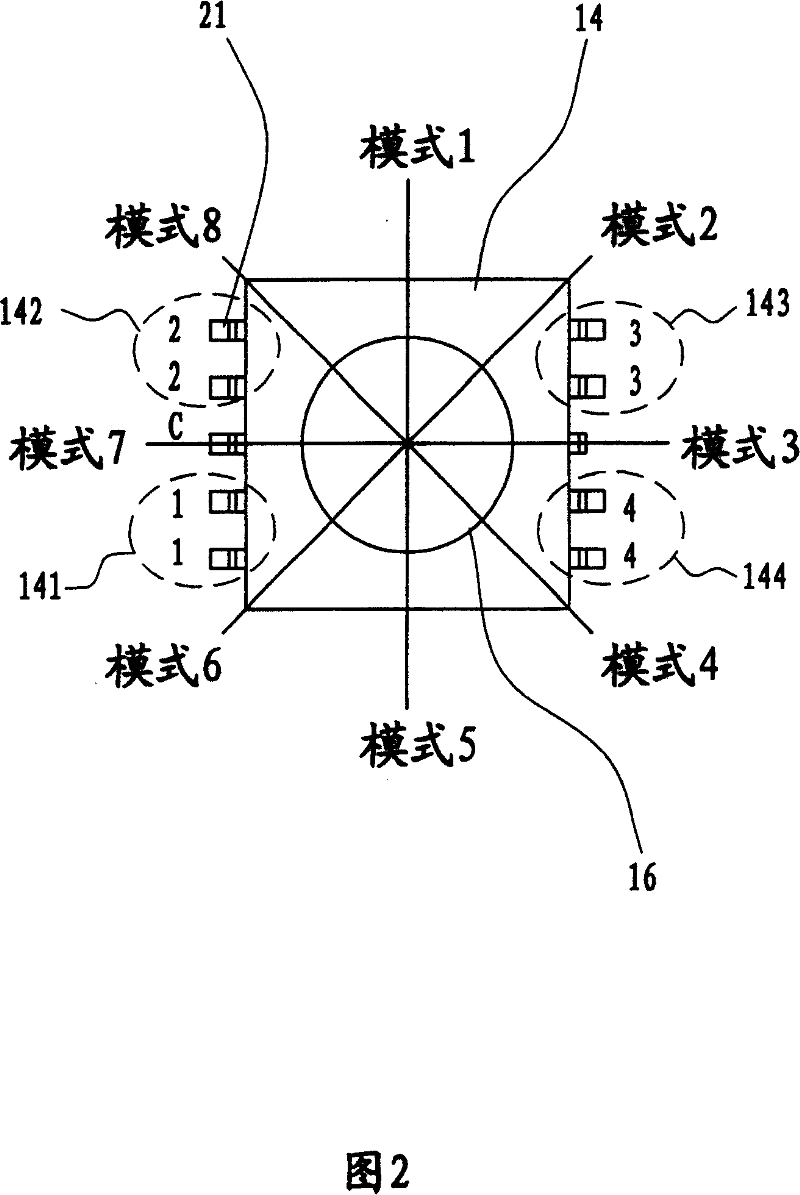

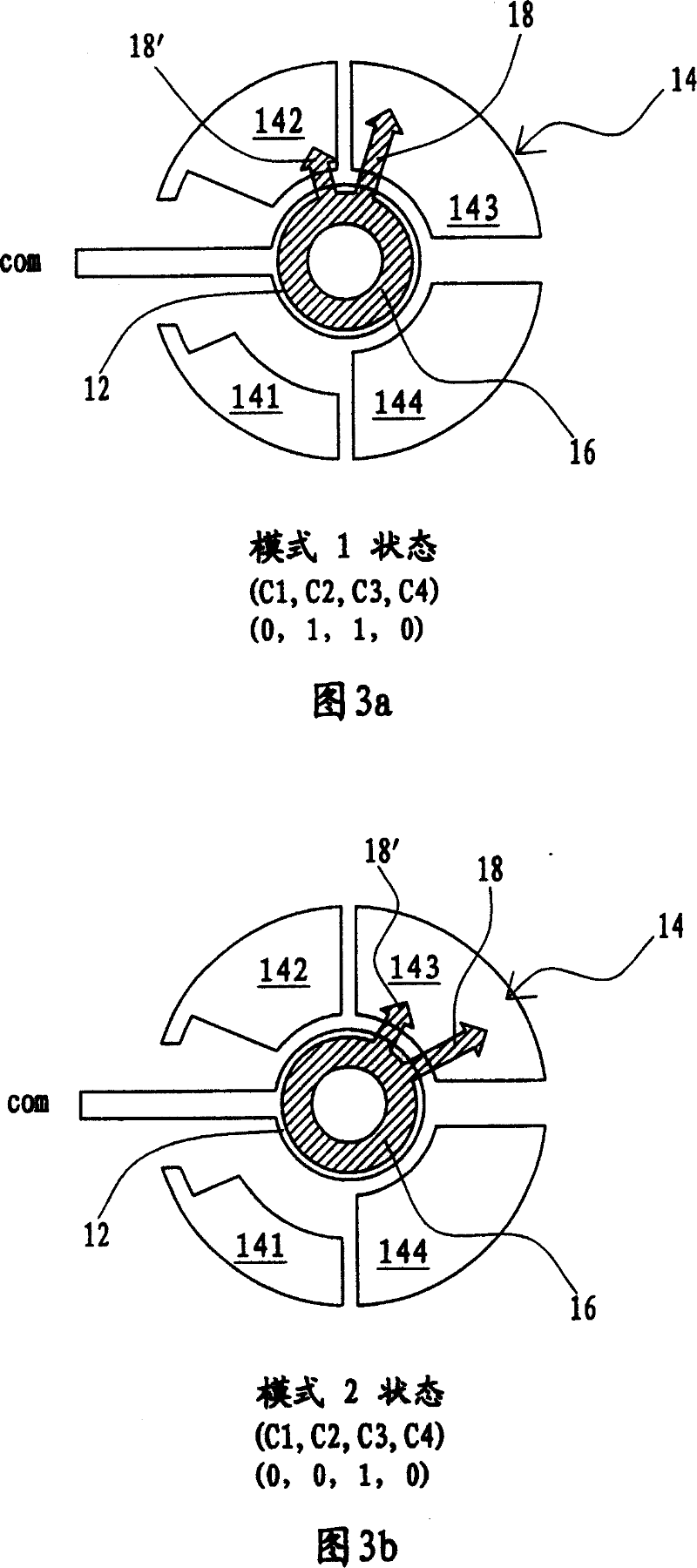

[0033] As shown in FIG. 1 , it is a structural diagram of an embodiment of the present invention, which will be used to describe in detail the circuit structure of the present invention and the signal layout method for combining signals and power in the same switch. The mode switching structure 10 of the present invention includes a signal output contact 12, which is connected to a line 122 and extends outward; a mode configuration circuit 14 is arranged around the signal output contact 12, and it consists of four conductive contacts (Pad) 141 . Extend between the conductive contacts 141 and 142; there is also a rotatable mode switcher 16, which is provided with two conductive pins 18, 18', one long and one short, to bridge the signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com