Full automatic soya-bean milk making machine, and soya-bean milk making method with same

A fully automatic, soybean milk machine technology, applied in the field of kitchen utensils, can solve the problems of high blade speed, high working noise, and difficult cleaning of the filter screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

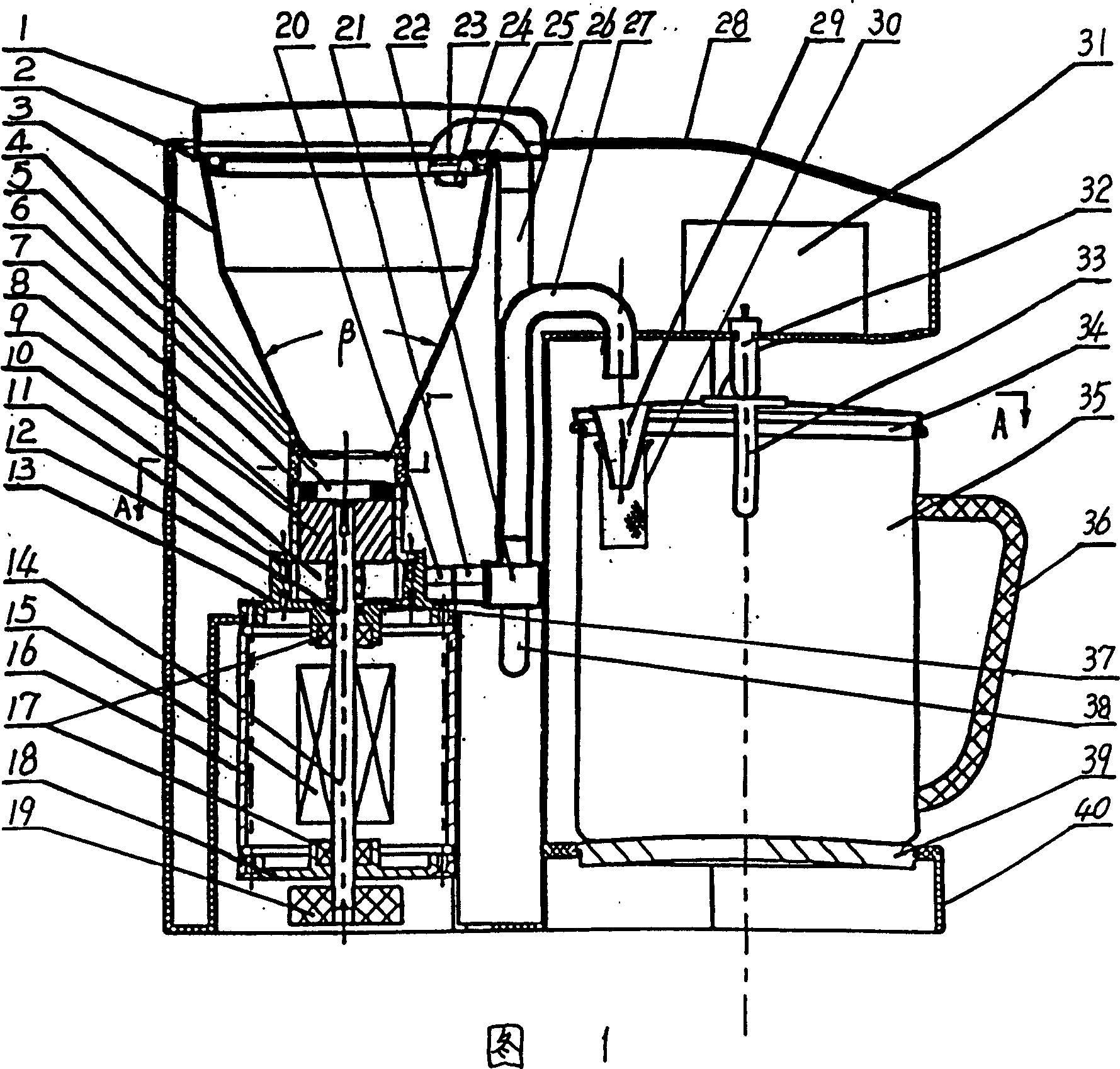

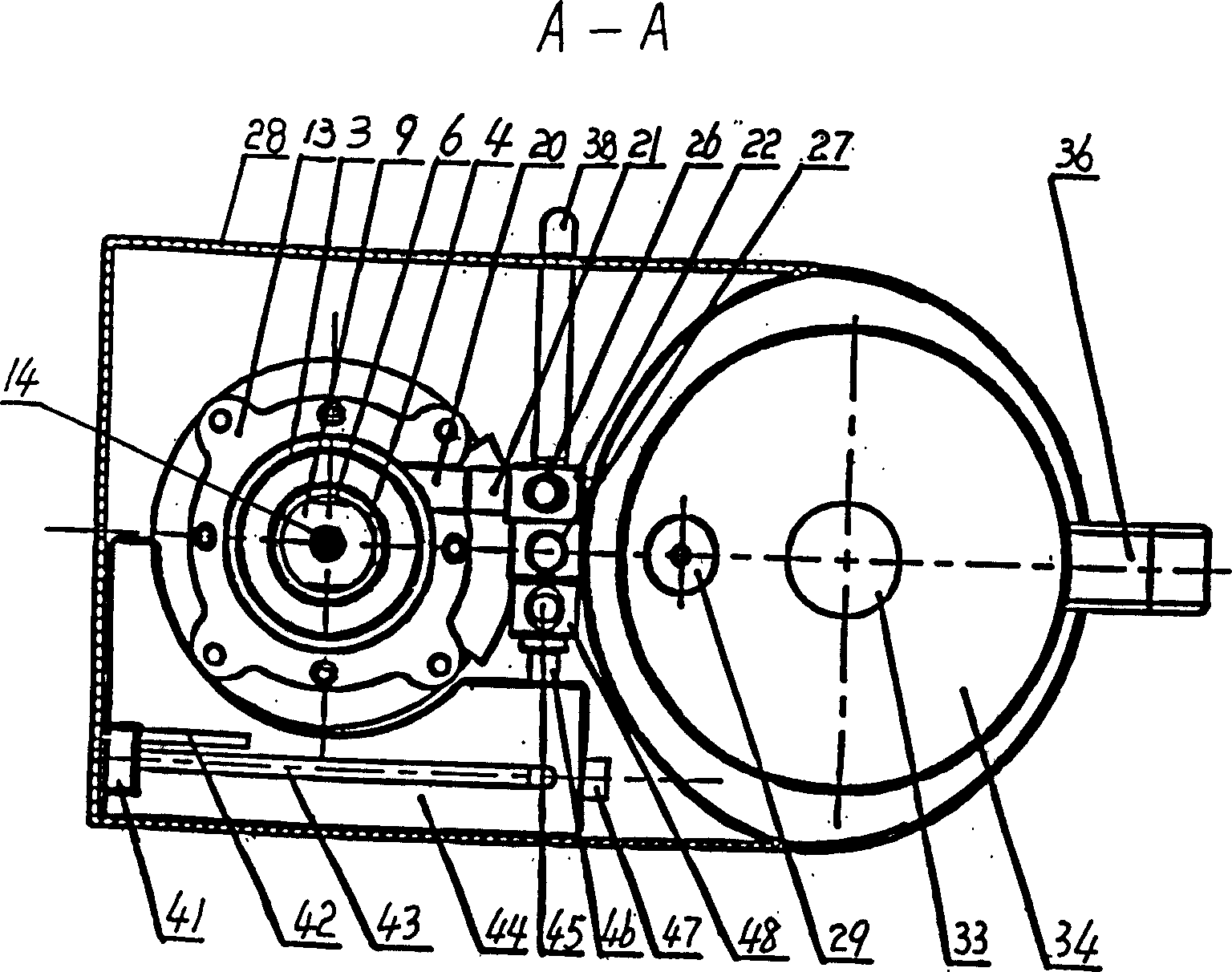

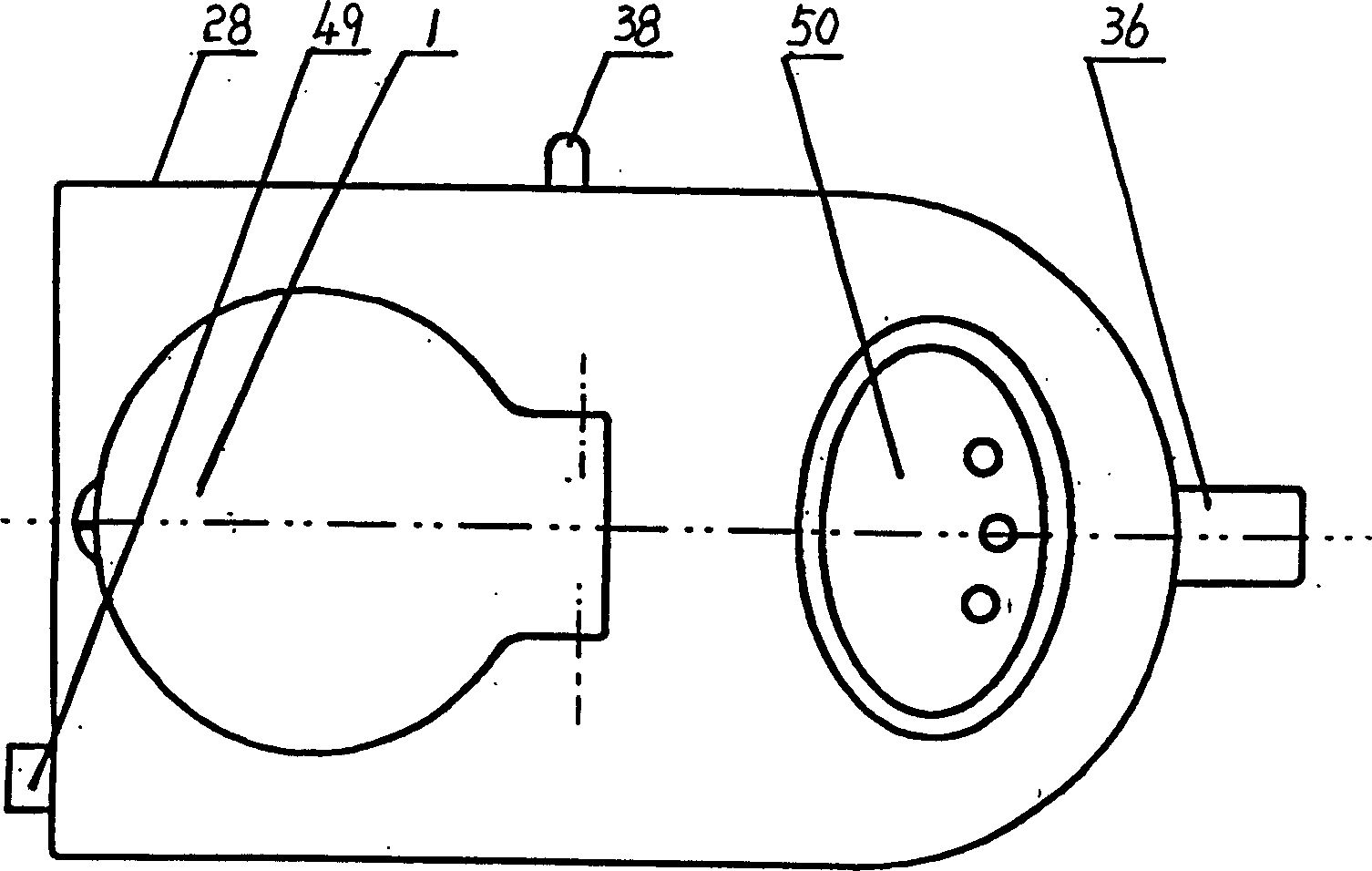

[0019] As a preferred embodiment of the automatic soymilk machine of the present invention, as shown in Figures 1, 2 and 3, the fully automatic soymilk machine includes a pulp making part, a pulp cooking part and a circuit control system:

[0020] a: The pulping part is composed of a pulping device, a water supply system, a circulation system, a motor and a control circuit board. The pulping device includes a fixed grinding head 8 and a moving grinding head 9. There is a dynamic rotation gap between them, and the moving grinding head 9 is fixed to the long axis 14 of the motor; the water supply system consists of a water tank 44, a water pump 48, a water pump inlet pipe 46, a water pump outlet pipe 45, a water inlet valve 49, a drainer 2 and a drainer inlet pipe 23 Composition, a heating device fixing plate 41 and a water level sensor identifier 47 are fixedly installed on the wall of the water tank 44, an electric heating tube 43 and a temperature sensor 42 are inserted on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com