Hybrid compressor system

A compressor system and hybrid technology, applied in the direction of liquid variable capacity machinery, electromechanical devices, mechanical equipment, etc., can solve the problem of increasing the size of the motor and external power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

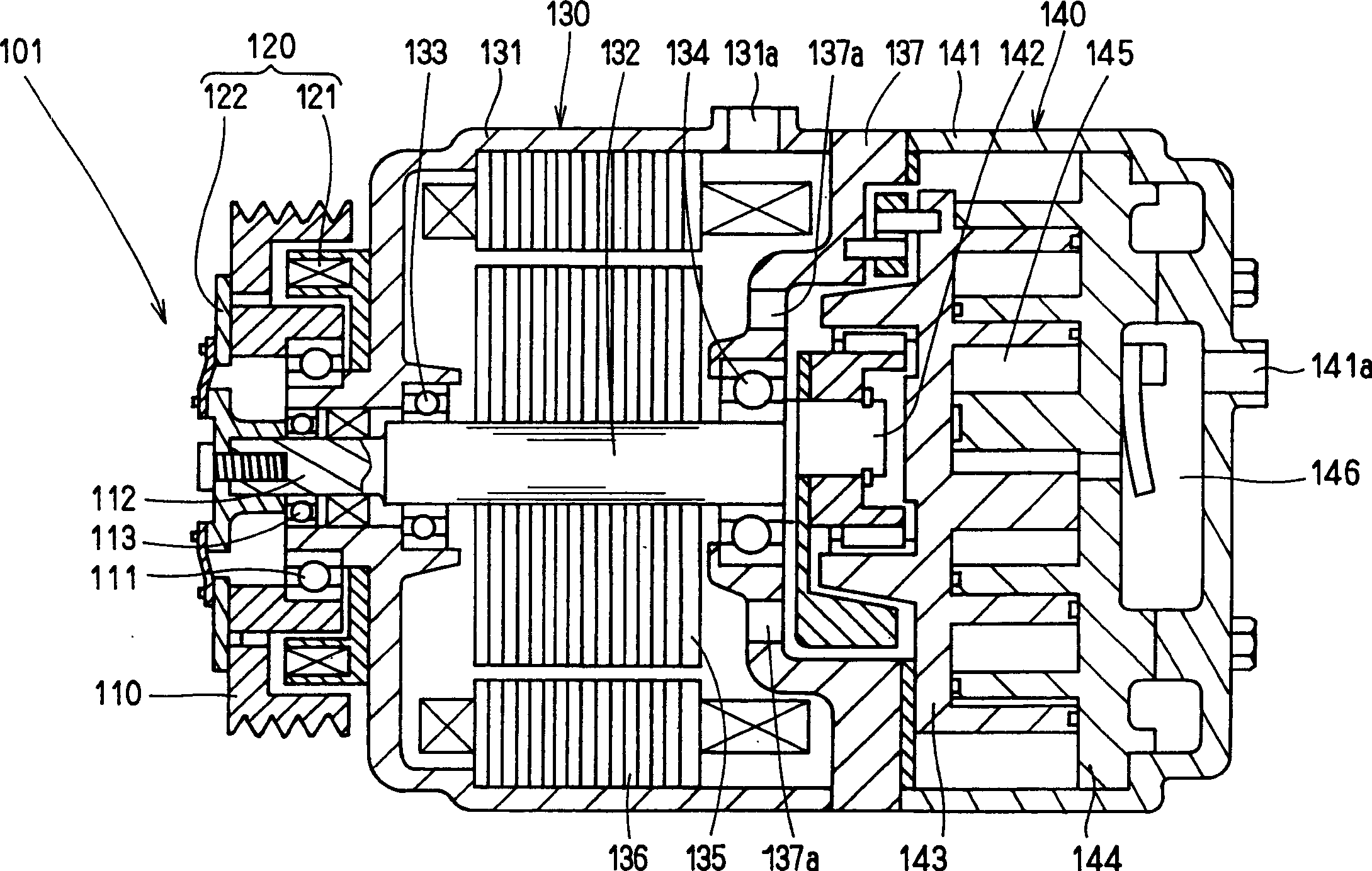

[0047] The following will refer to Figure 1 to Figure 4 Description such as Figure 1 to Figure 8 Shown is a specific structure according to a first embodiment of the invention.

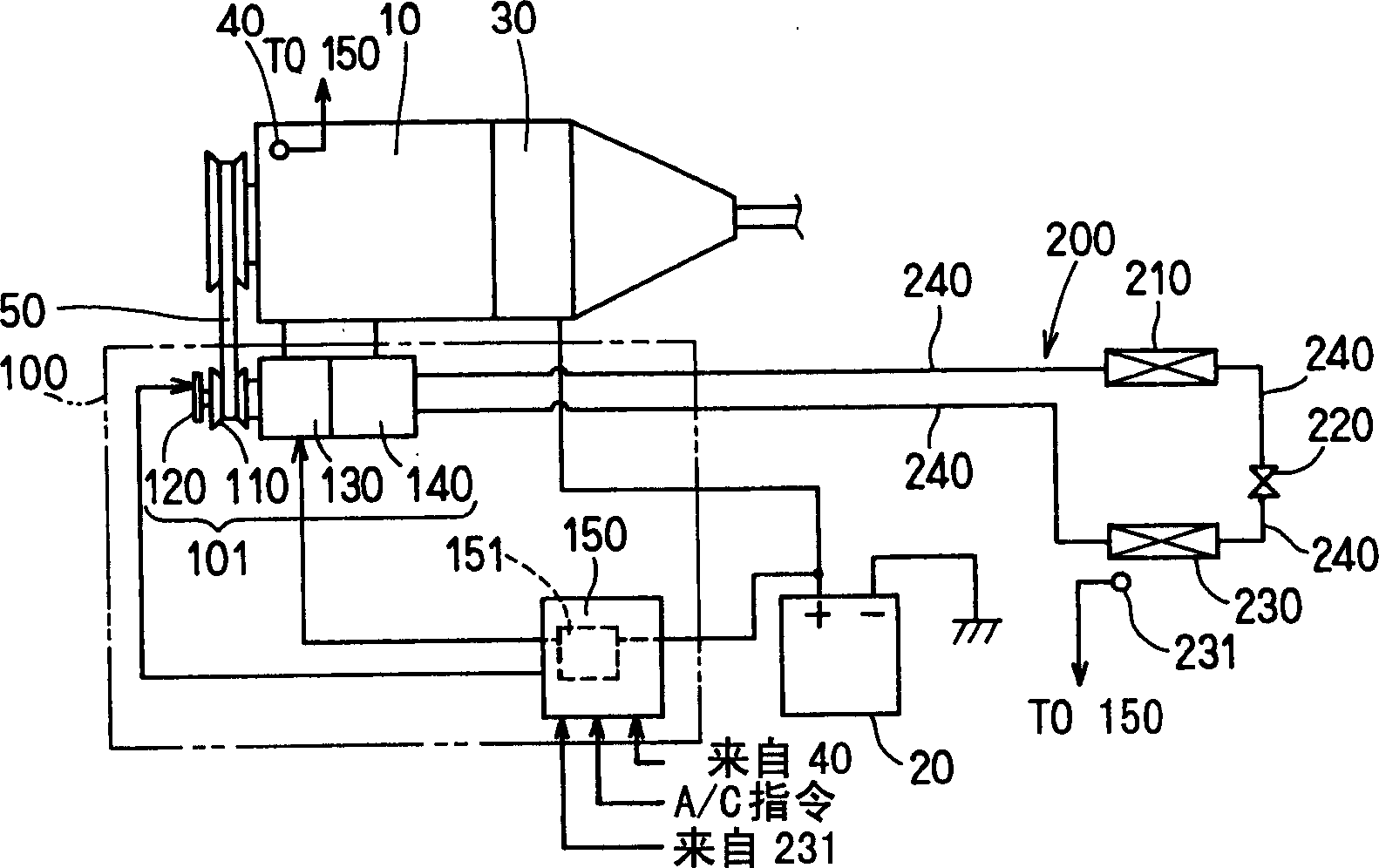

[0048] Such as figure 1 As shown, the hybrid compressor system 100 is applied to a refrigeration cycle system 200 installed in a dual power type vehicle in which a vehicle engine (hereinafter referred to as an engine) 10 is stopped according to its operating conditions. The hybrid compressor system 100 includes a hybrid compressor 101 and a controller 150 serving as a control means. In addition, the dual power type vehicle has a motor generator (generator) 30 directly connected to the engine 10 , which is provided with a rotational speed sensor 40 for detecting the rotational speed of the engine 10 .

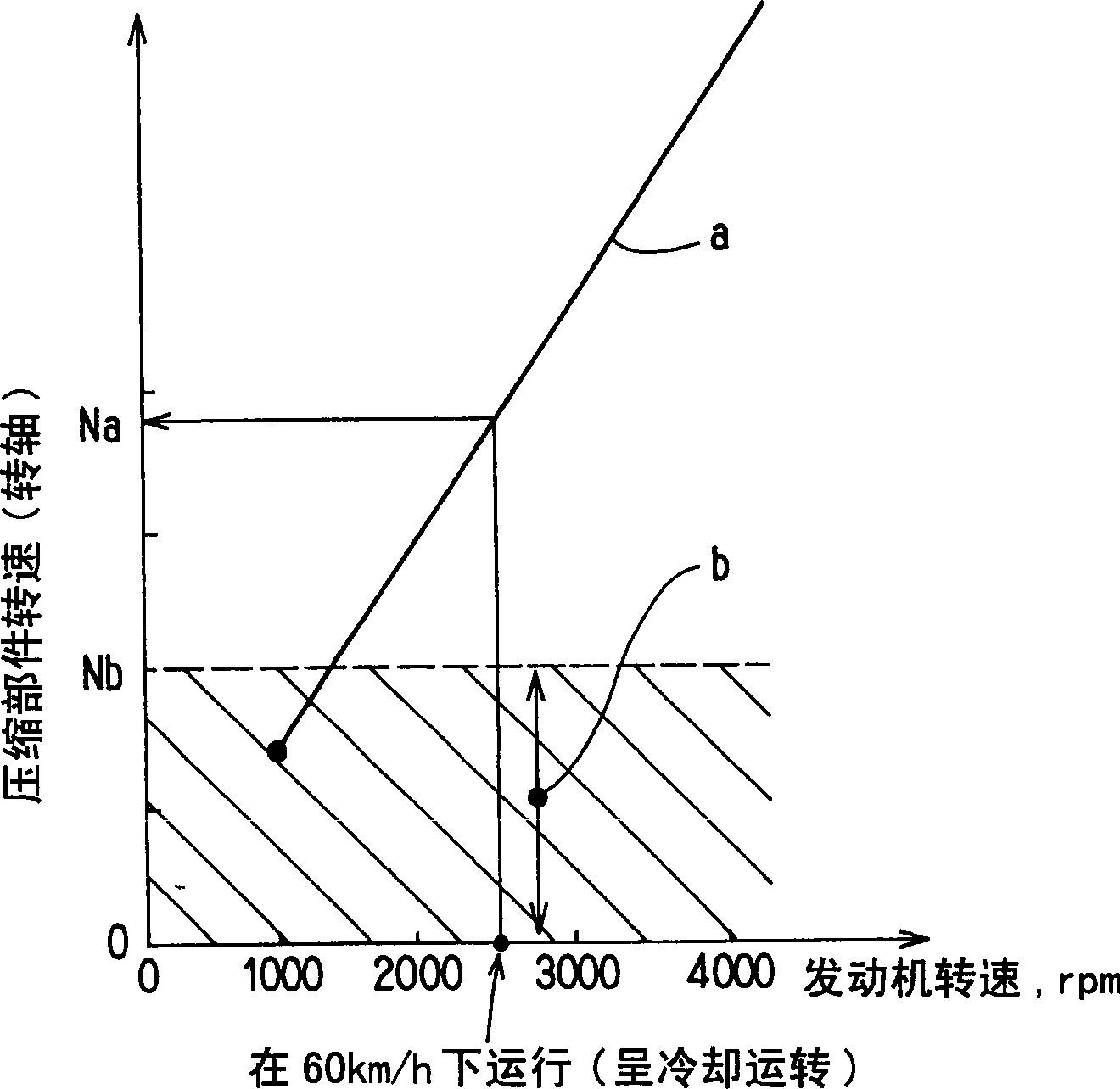

[0049] The refrigerating cycle system 200 provides a known refrigerating cycle and is provided with a compression unit 140 which constitutes the hybrid compressor 101, which will be described later...

no. 2 approach

[0077] Figure 9 The second embodiment of the present invention has been described. In the second embodiment, between the pulley 110 and the compressing member 140, more precisely, between the pulley 110 and the motor 130, a gear mechanism is provided as a speed increasing device. In this embodiment, the gear mechanism is embodied as a planetary gear 170 . Among the gears forming the planetary gear 170 , the sun gear 171 is connected to the engine shaft 132 , and the planetary gear 172 is connected to the pulley shaft 112 . A ring gear 173 forming an outer circumferential portion of the planetary gear 170 is fixed to the boss portion 131b near the bottom of the engine frame 131 .

[0078] This configuration enables the rotational speed to provide the maximum displacement required by the engine 10 to operate the compression member 140 . This in turn enables the compression member 140 to provide its smaller displacement per revolution, reducing both the size and manufacturing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com