Hollow member ,manufacturing method, thereof, fluid distribution system using hollow member, and forming apparatus of hollow member

A technology for fluid distribution and forming equipment, applied in the direction of manufacturing tools, mechanical equipment, welding equipment, etc., can solve the problems of inability to reduce manufacturing costs, poor appearance, and larger equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] In the following description and drawings, the invention will be explained in detail on the basis of a preferred embodiment.

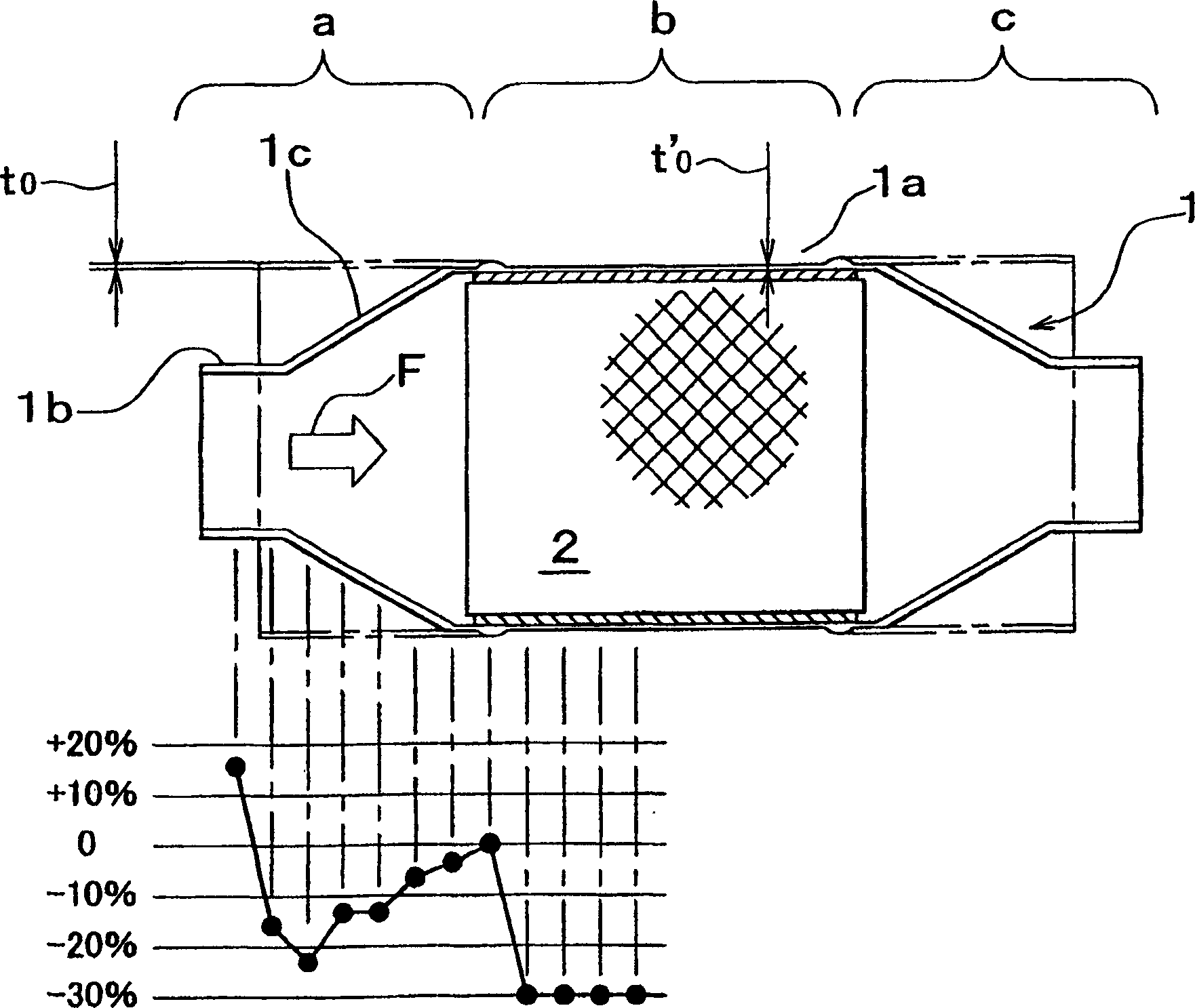

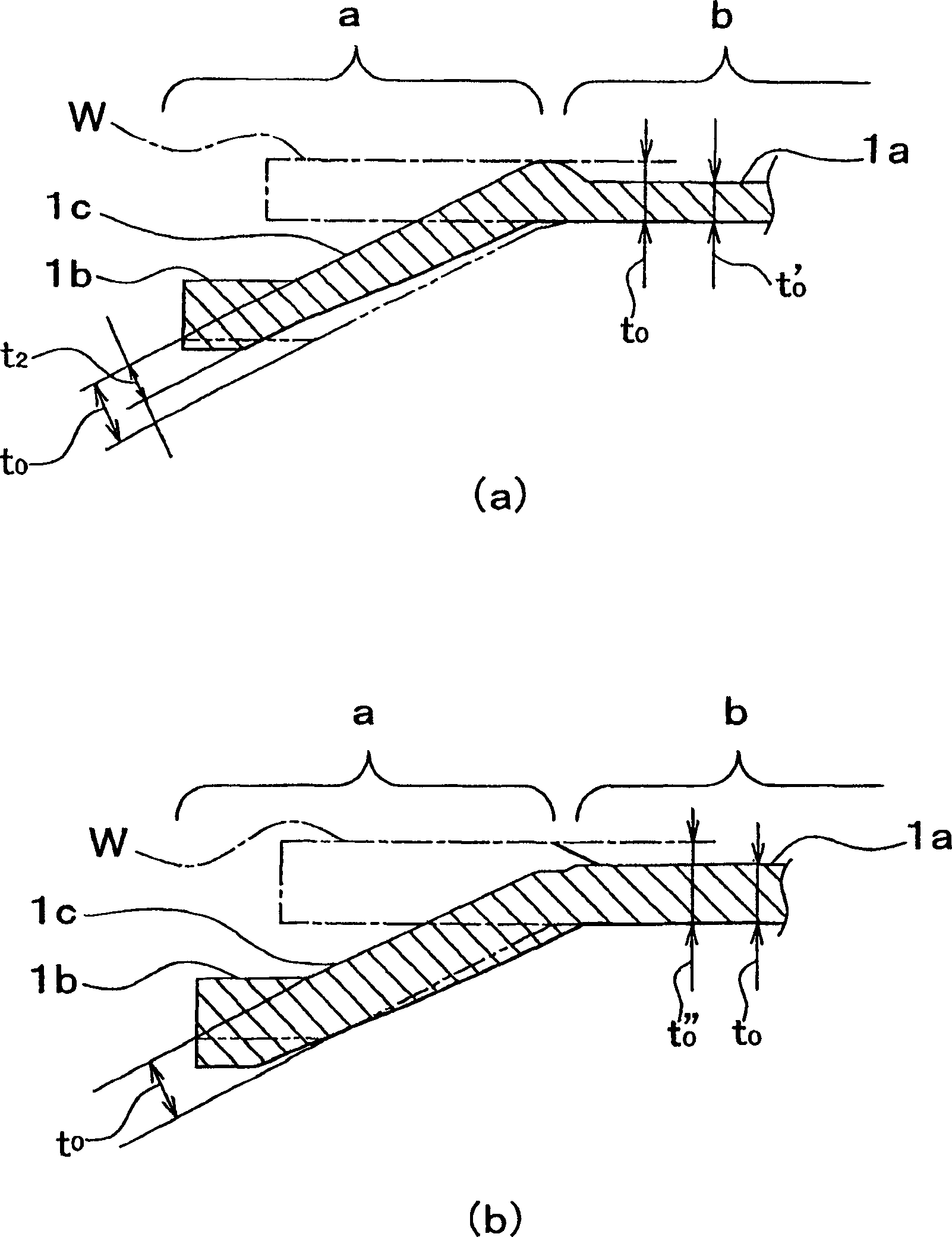

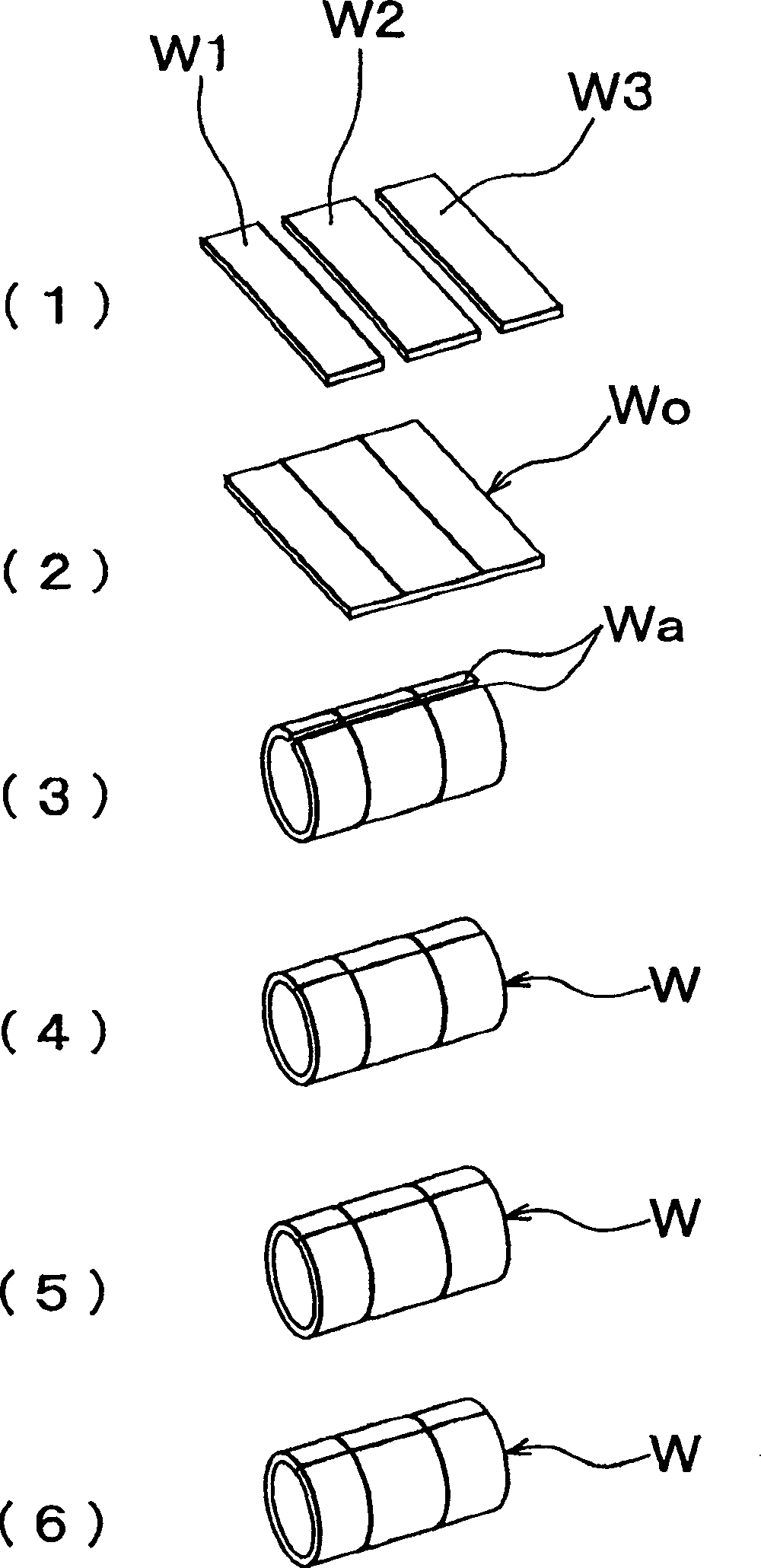

[0086] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings, wherein the fluid distribution system is an exhaust system for purifying exhaust gas of a combustion engine such as an internal combustion engine, and the hollow member is a catalytic converter for fixing a catalyst carrier inside Catalyst container 1. Here, the same parts as in the conventional art are denoted by the same reference numerals, and detailed description thereof will be omitted. In this specification, the cylindrical part in this method is called "hollow material", and after the spinning process for making the hollow material into a predetermined shape is completed, the changed cylindrical part whose cross-sectional shape is drawn is It is called "hollow member".

[0087] figure 1 A sectional view showing a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com