Organic white light fluorescent luminous material and its preparing method

A luminescent material and fluorescence technology, applied in luminescent materials, chemical instruments and methods, sustainable buildings, etc., can solve the problem of not many photoluminescent WLEDs, and achieve the effect of improving color temperature and color coordinates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

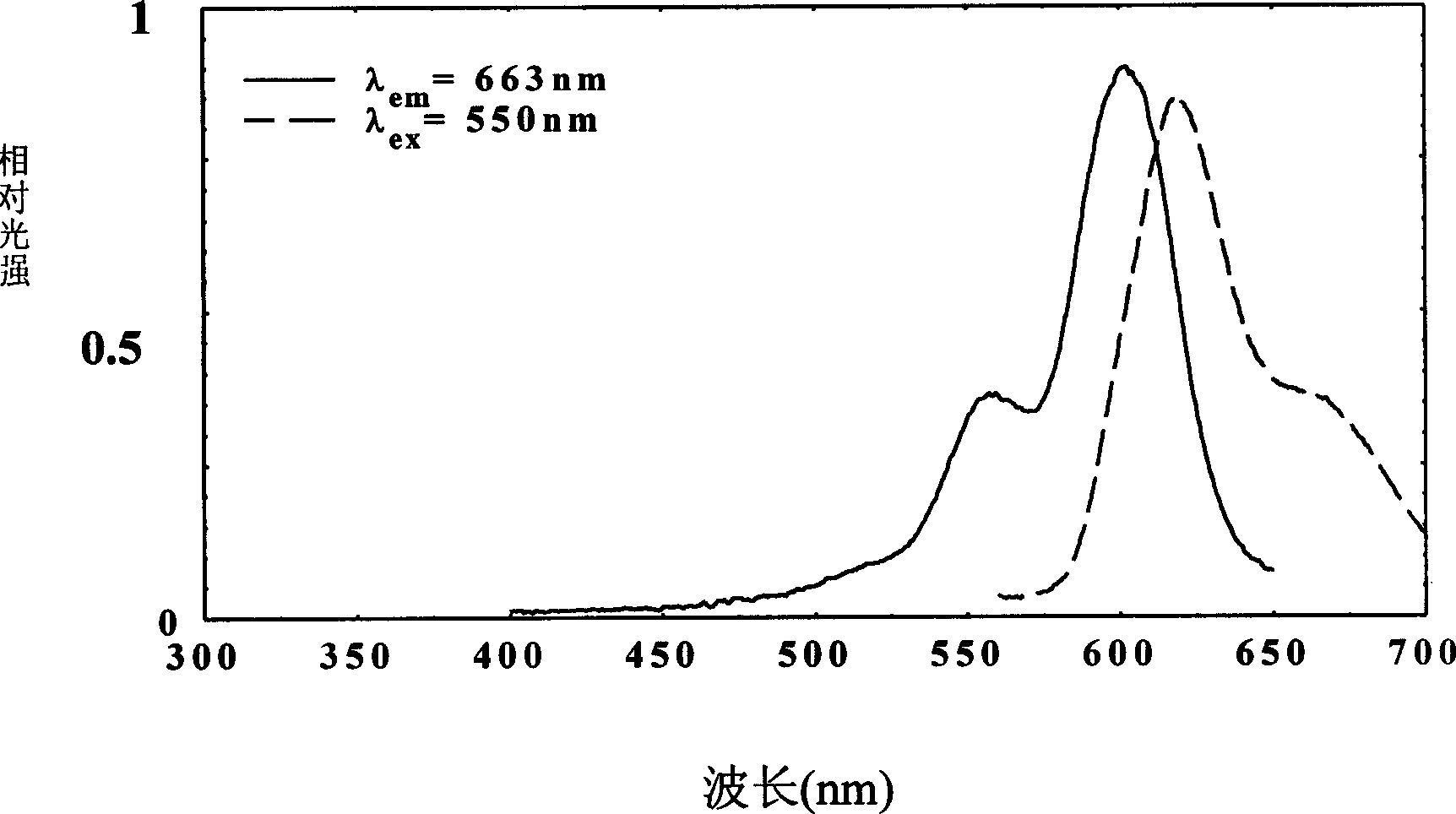

[0011] Weigh reduced dark blue: 0.1g LLDPE: 10g, mix and stir for 20-40min, then take 0.1g mixture, LLDPE: 10g, mix and stir for 20-40min to obtain 1:10 4 mixture. Take 1g of 1:10 4 Put the mixture on a ceramic plate coated with liquid paraffin, heat them to a molten state on an electric furnace at 180°C, stir the molten mixture with a stirring rod coated with liquid paraffin, make it further completely mixed, and spread it evenly into about 0.5 mm thick film, then heated for 5 minutes to remove. After cooling, it can be scraped off with a knife to obtain an organic luminescent film that emits red light. The film can encapsulate green LED tube cores with a wavelength of 540nm-560nm to generate white light. Its excitation and emission spectra are as figure 1 . Example 2

example 2

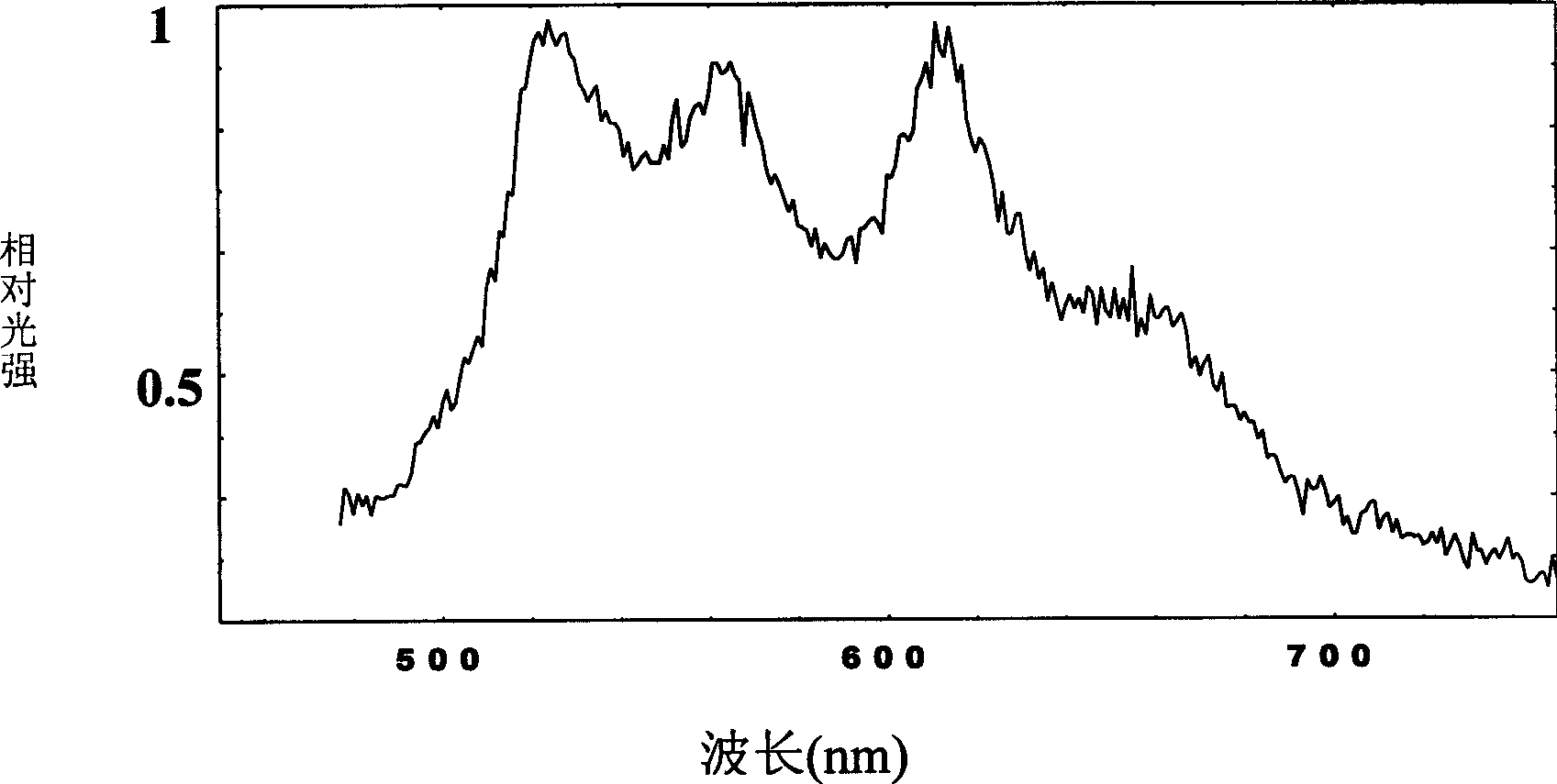

[0012] Weigh riboflavin: 0.1g, reduced violet 0.3g, LLDPE: 10g. First put riboflavin and reduced violet into 5ml of deionized water, stir evenly, pour into LLDPE, mix and stir for 20-40min, put into drying oven for 90min. Then take 0.1g of the mixture, LLDPE: 10g, mix and stir for 20-40min to obtain 4:10 4 mixture. Take 1g of 4:10 4 Put the mixture on a ceramic plate coated with liquid paraffin, heat them to a molten state on an electric furnace at 190 ° C, stir the molten mixture with a stirring rod coated with liquid paraffin, make it further completely mixed, and spread it evenly into about 0.5 mm thick film, then heated for 5 minutes to remove. After cooling, scrape it off with a knife to get an organic luminescent film that emits yellow-green light and red light. The thin film can encapsulate blue LED tube cores with a wavelength of 450nm-470nm to generate white light. Its emission spectrum is as figure 2 .

[0013] The conjugated compound of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com