Detecting method for cold rolled steel strip inner stress

A detection method and technology of strip steel shape, applied in the direction of measuring force, measuring device, instrument, etc., can solve the problems of high cost, difficult operation, and high equipment requirements, and achieve the improvement of punching forming performance, simple operation method, and low equipment requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

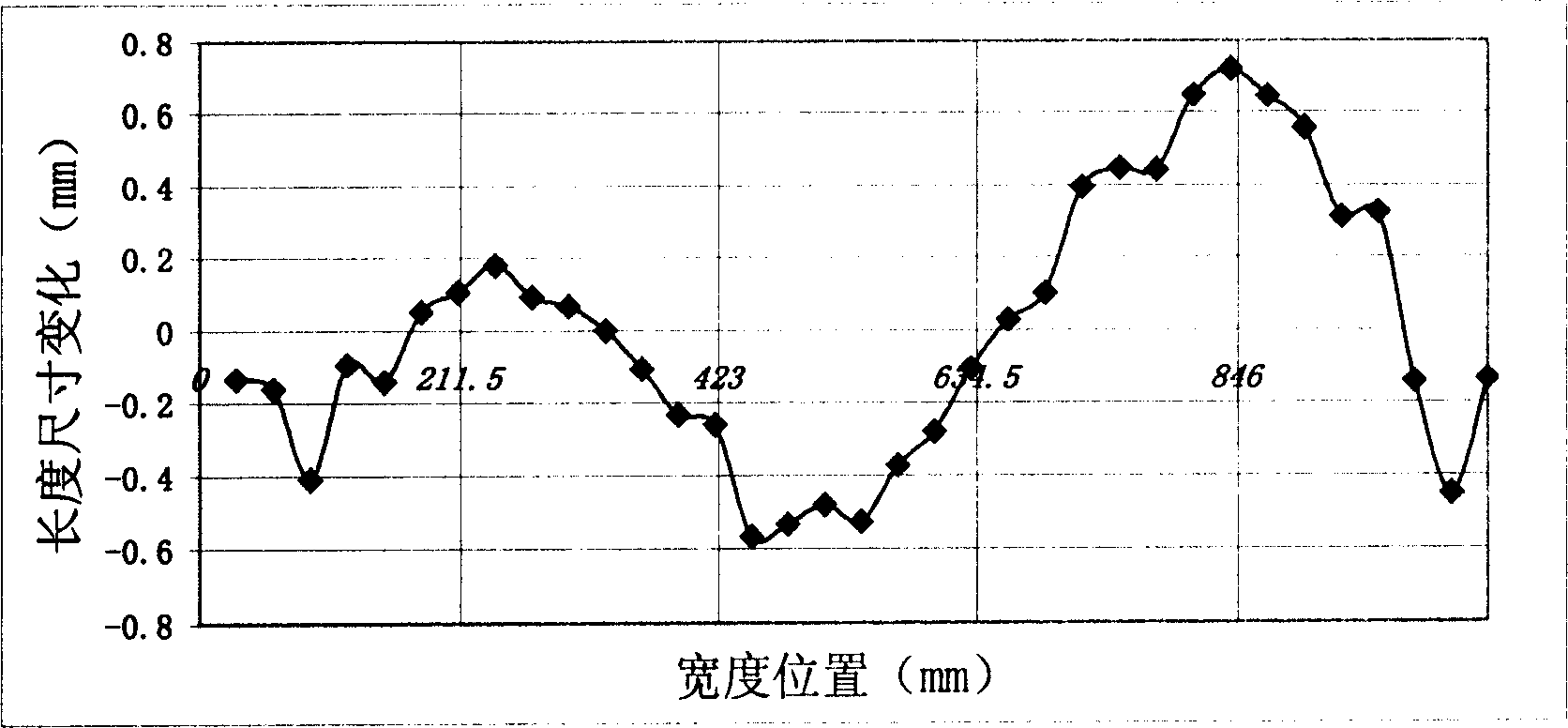

[0026] Embodiment 1: The object tested in this embodiment is a non-oriented cold-rolled silicon steel strip that has not been annealed. First cut a test sample with a length of 1000mm, and the width of the test sample is 1022mm. Align the two ends of the test sample on the shears to ensure the effective length of the test sample. Cut the sample slices according to the size of 30mm in the rolling direction, put them in order, then use the vernier caliper to measure the length of the sample slices, and use the coordinate curve to describe the length and dimension changes of the test sample slices (see figure 1 , the horizontal axis in the figure represents the width position corresponding to the detection sample slice, and the vertical axis represents the length dimension change of the sample slice), and finally according to Hooke’s law, that is, the formula σ=G·ε=G·Δl / L, at this time G =197×10 3 MPa, the change of the length dimension of the sample slice is converted into the ...

Embodiment 2

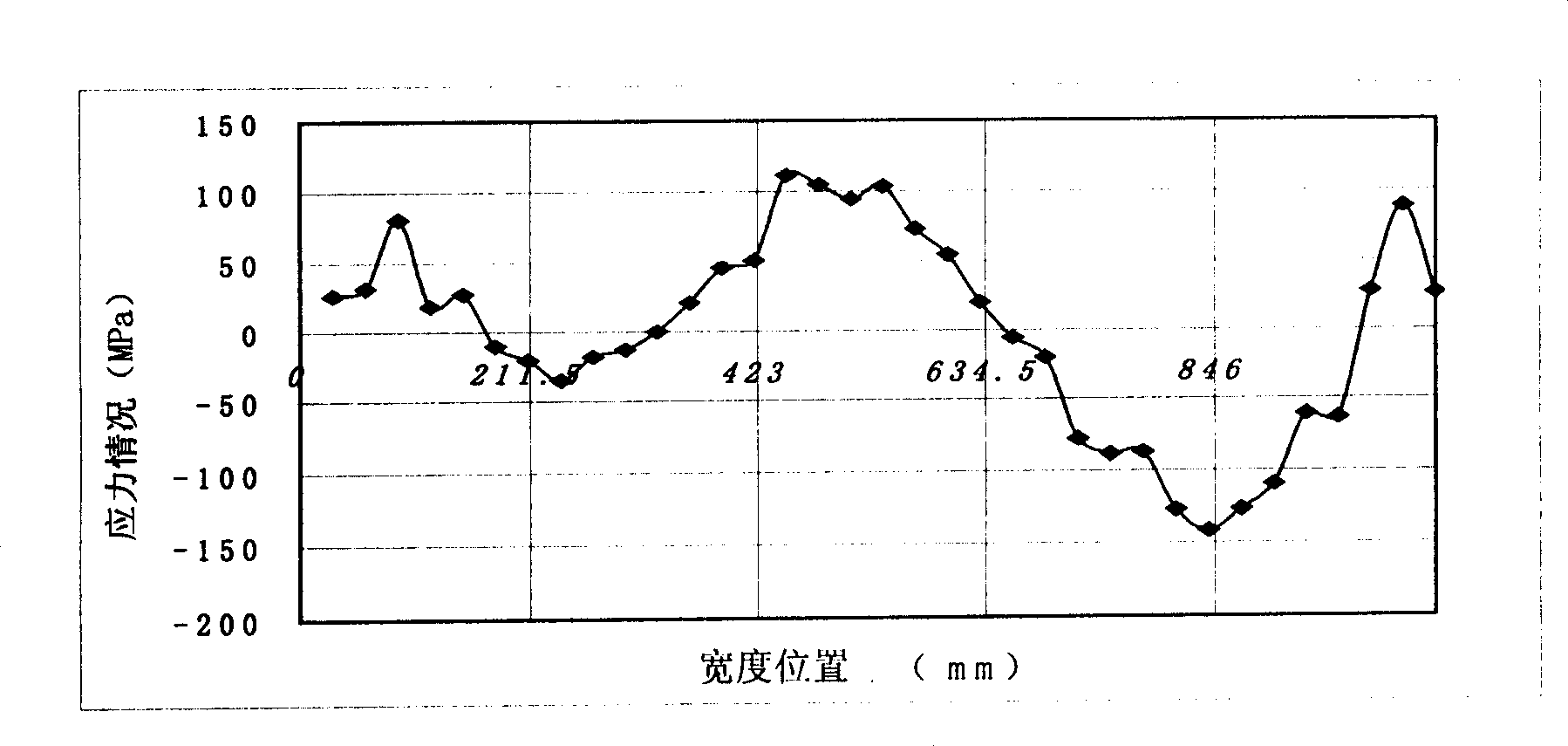

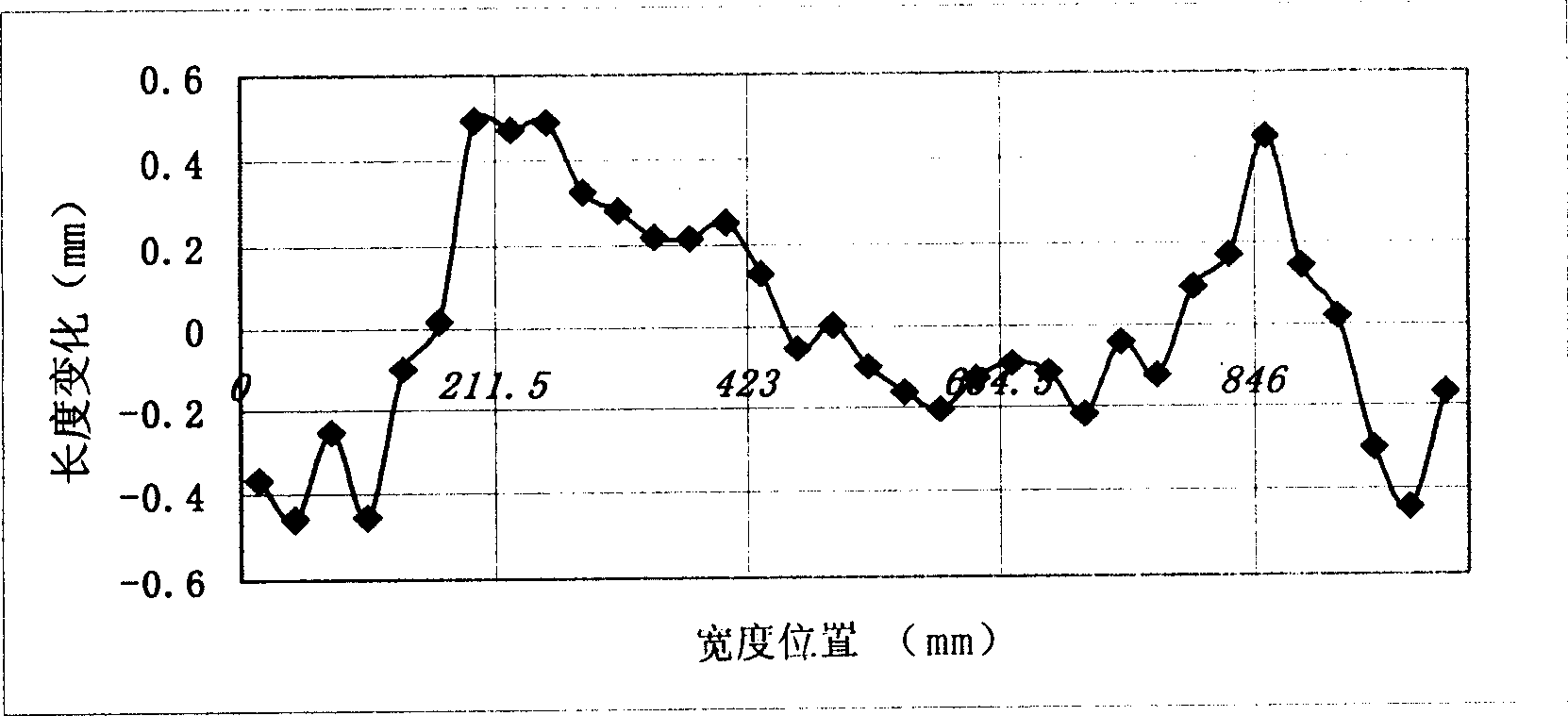

[0028] Example 2: The object tested in this example is a non-oriented cold-rolled silicon steel strip that has been annealed and coated. The length of the test sample is 1000mm, the width is 1022mm, and the length of the sample slice is 25mm. The length and dimension change curve of the test sample slice is as follows: image 3 As shown (the horizontal axis in the figure represents the width position corresponding to the test sample slice, and the vertical axis represents the length and dimension change of the sample slice), the test sample plate shape internal stress distribution curve is as follows Figure 4 (the horizontal axis in the figure represents the width position corresponding to the test sample slice, and the vertical axis represents the stress suffered by the sample slice).

[0029] From the test results of this example image 3 , Figure 4 It can be seen that there is a large internal stress in the shape of the cold-rolled sheet, and the maximum stress reaches ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com