Power converter and power generator

A power generation device and power conversion technology, which is applied in circuit devices, output power conversion devices, adjustment of electrical variables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

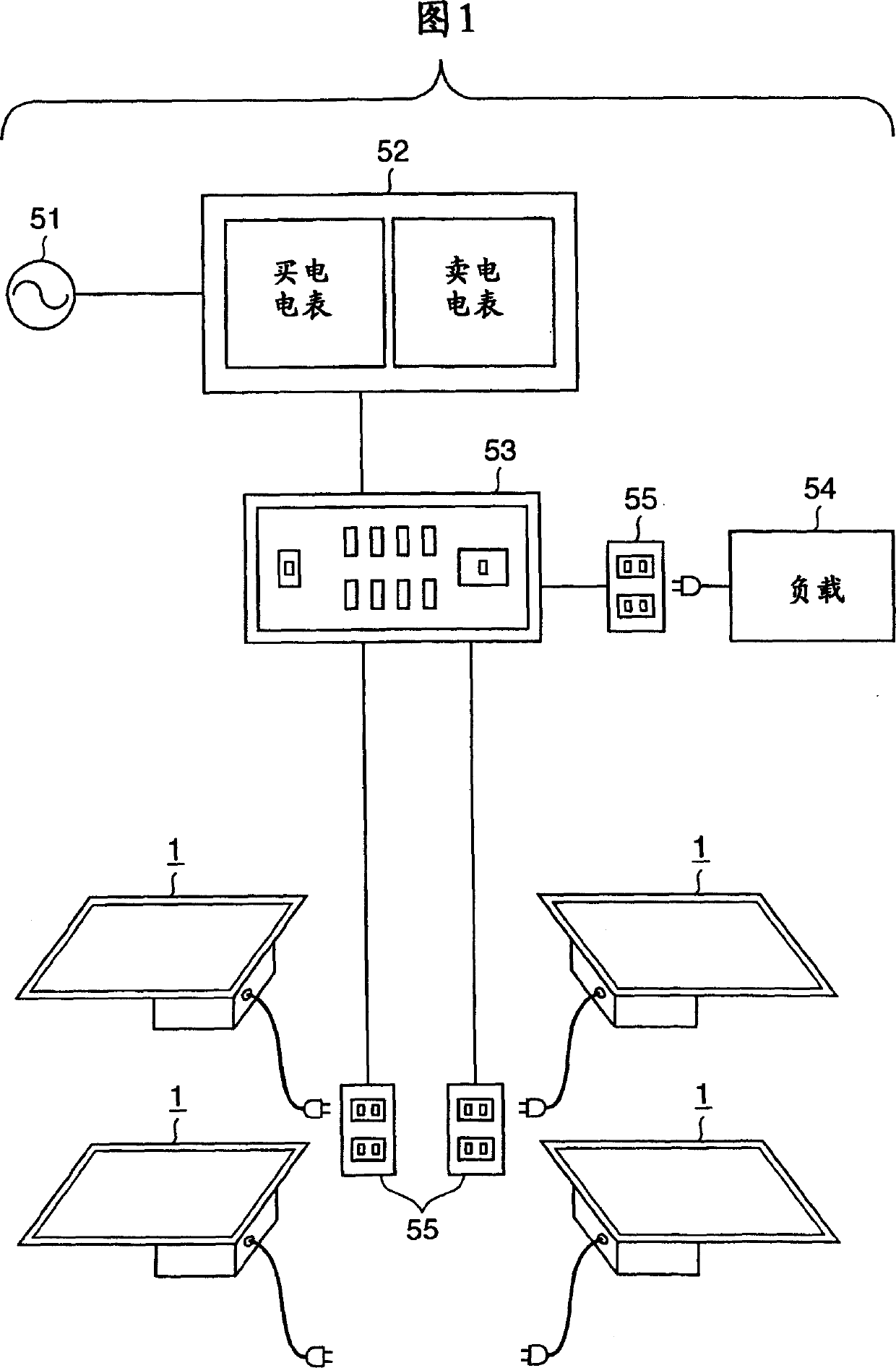

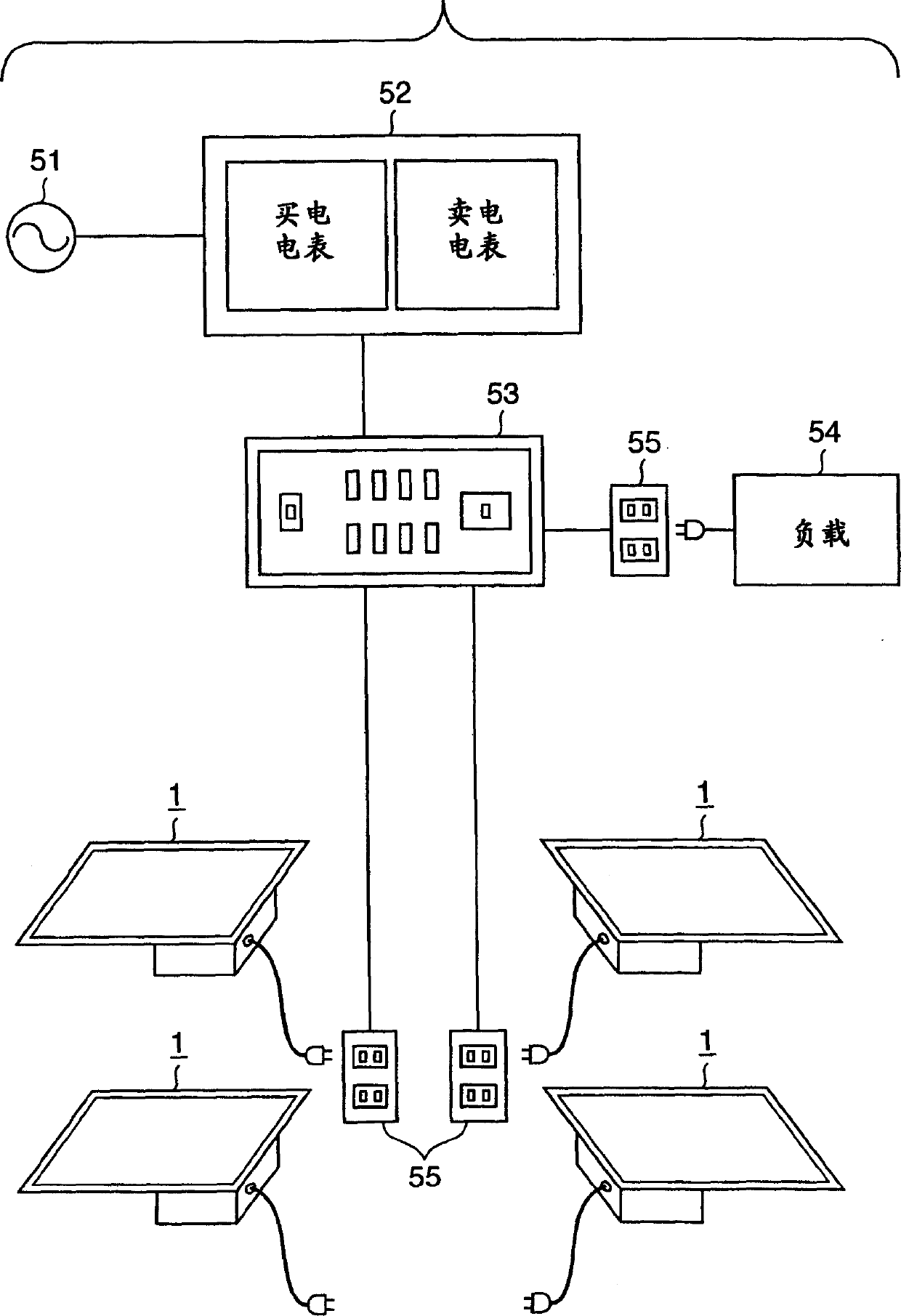

[0089] Embodiment 1 is an example in which a thin-film solar cell in which amorphous and microcrystalline layers are laminated is used as the solar cell 7 . In addition, since the structure or manufacturing method of the laminated solar cell and the mounting method of the collecting electrodes are irrelevant to the essence of the present invention, detailed explanations are omitted, and they are disclosed in JP-A-11-243219 or JP-A-8-139439 Bulletin etc.

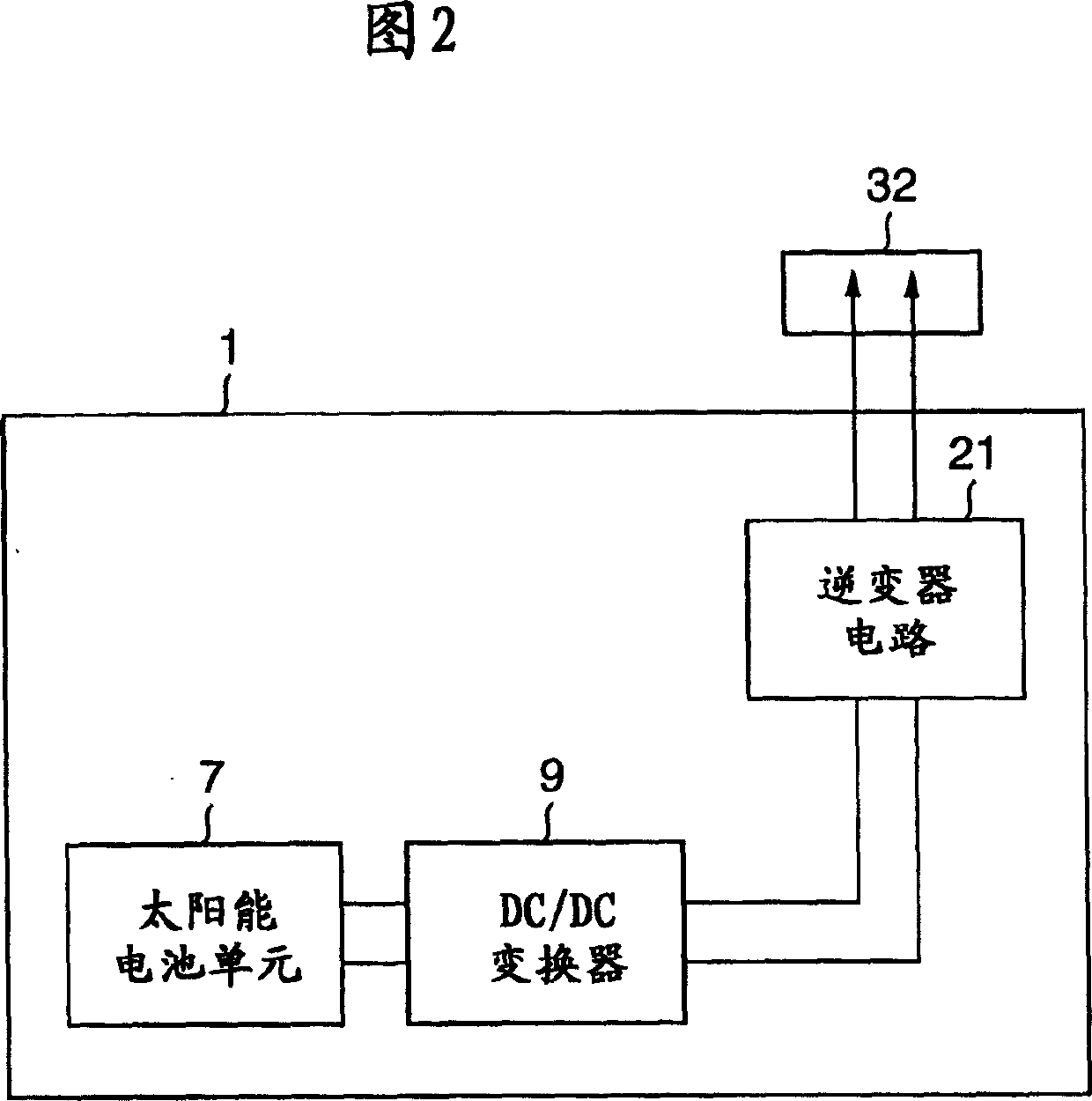

[0090] The single unit performance of the solar battery unit 7 is an output of 1.0V, 15.0A in rated sunlight (spectrum AM1.5, 100mW / cm2, unit temperature 55°C). A DC / DC converter 9 is installed in one solar battery unit 7 to form a power generation device.

[0091] transformer

[0092] If the minimum operating voltage of the solar battery unit 7 is set as 0.8V, then the boost ratio when the 100V system is used as the connection target can be 0.8:140=1:175, and in order to leave a margin, the variable voltage of the transfor...

Embodiment 2

[0105] In the second embodiment, the primary winding of the transformer 15 used in the DC / DC converter 9 is set to three turns. FIG. 21 shows the standard using the transformer 15 in Embodiment 2.

[0106] FIG. 7 is the same as FIG. 6, and plots the relationship between the power conversion efficiency of the DC / DC converter 9 in Embodiment 2 and the input voltage according to different input powers.

[0107] Compared with Example 1, the DC / DC converter 9 of Example 2 roughly shows that the conversion efficiency is good when the sunlight is low (input power is 1 to 8W), and the conversion efficiency is good when the sunlight is high (input power is 9 to 15W). tendency to decrease.

Embodiment 3

[0118] In Example 3, a solar battery cell in which three photoelectric conversion layers including amorphous silicon were laminated was used as the solar battery cell 7 . A method of manufacturing such a solar battery cell is disclosed in JP-A-6-21494 and the like.

[0119] The performance of the solar battery cell 7 is 1.5V, 30W in rated sunlight (spectrum AM1.5, 100mW / cm2, cell temperature 55°C). In addition, the optimum operating point voltage of the solar battery cell 7 varies between 1.2 and 1.8 V according to changes in the environment (sunlight, temperature).

[0120] The DC / DC converter 9 is the same as other embodiments, and is composed of a push-pull circuit, its switching frequency is 40kHz, and the duty ratio is fixed at 50%. Here, since the voltage of the solar cell 7 is different from that of the first embodiment, the transformation ratio of the transformer 15 used is changed.

[0121] transformer

[0122] Since the minimum value of the optimal operating point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com