Laser vibration detestion method and its equipment

A vibration detection and laser technology, which is applied in the direction of measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of inability to obtain the measured amplitude value, low measurement resolution, and inability to obtain displacement, etc., so as to achieve simple debugging and improved Signal-to-noise ratio, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and examples.

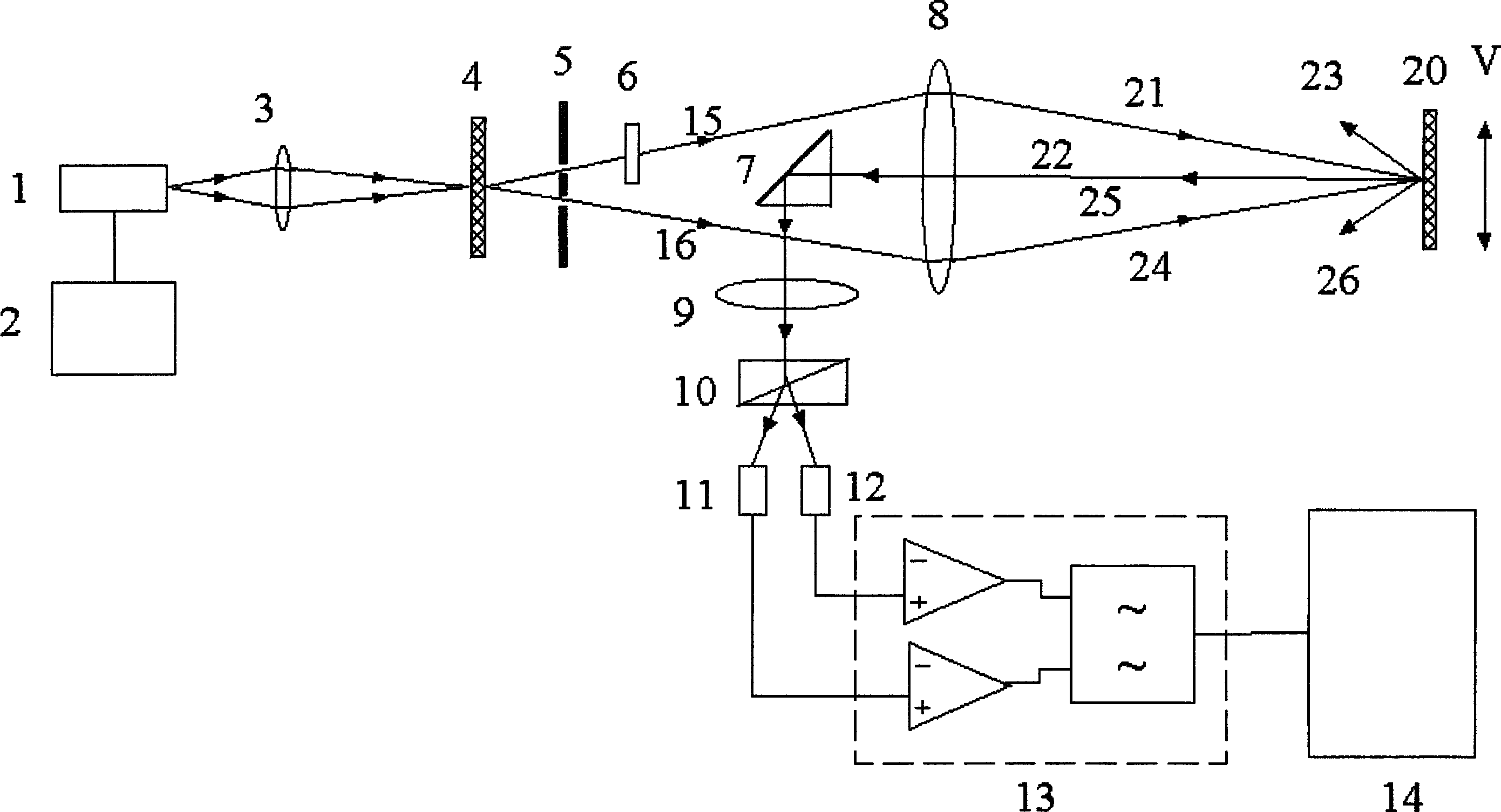

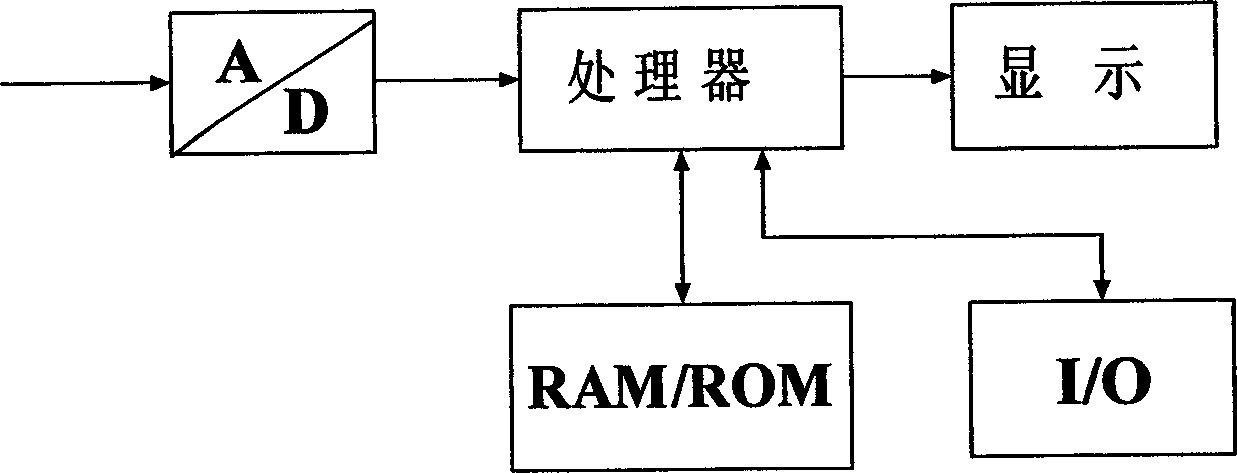

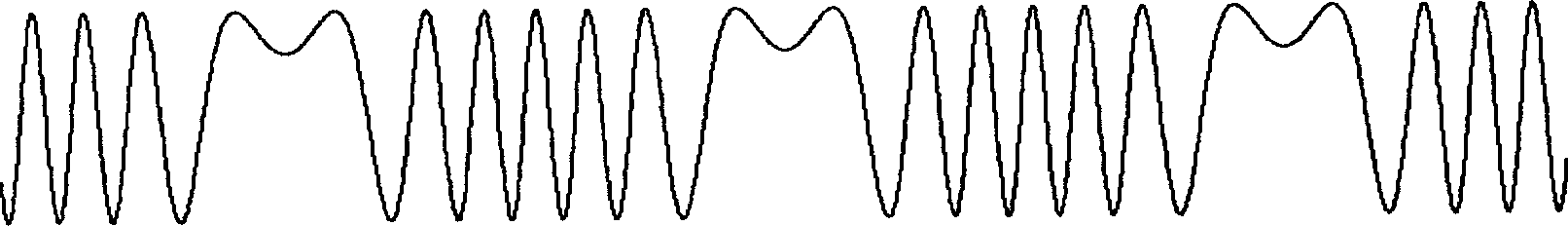

[0025] exist figure 1 Including laser 1, laser power supply 2, focusing lens 3, transmission grating 4, diaphragm 5, λ / 4 wave plate 6, reflecting prism 7, focusing lens 8, frequency mixing element 20, reflecting prism 7, lens 9, splitter Beamer 10, photoelectric receivers 11, 12, amplifying circuit unit 13, signal processing unit 14 and so on. The laser beam emitted by the laser 1 is focused by the lens 3 to the transmission grating 4, and diffraction occurs, and 0-order, ±1-order, ±2-order, ... diffracted lights are emitted, and the aperture 5 filters out +1-order light 15, - Other diffracted light other than the first-order light 16. These two beams of light are transformed by the lens 8 into beams 21 and 24 that are converged to the mixing element 20 and diffracted. The ±1st order lights diffracted by the beam 21 are 22 and 23; Adjusting the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com