Carburetor device

A carburetor, fuel tank technology, applied in carburetor, charging system, machine/engine, etc., can solve the problem of fuel feeding into the combustion chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

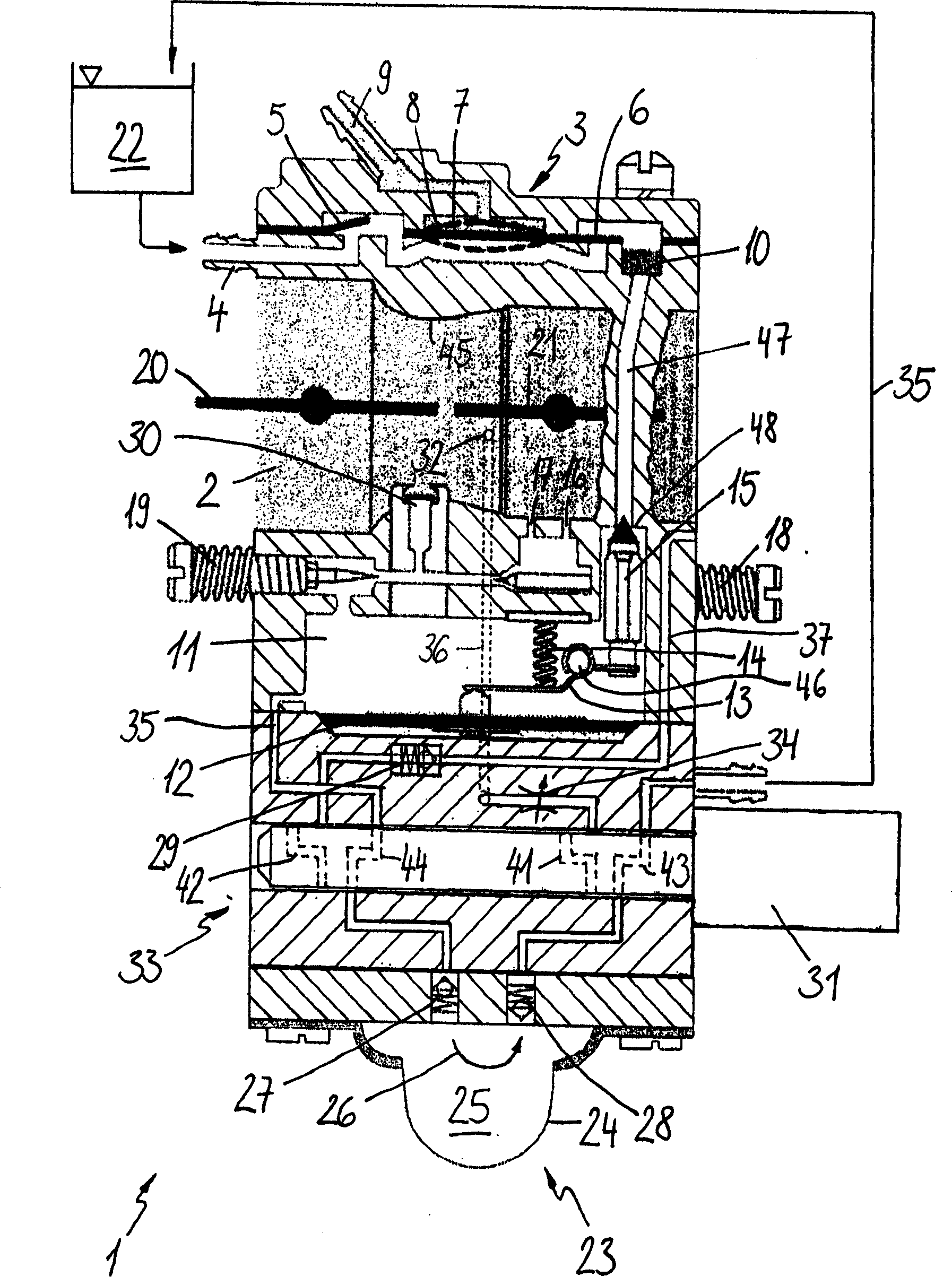

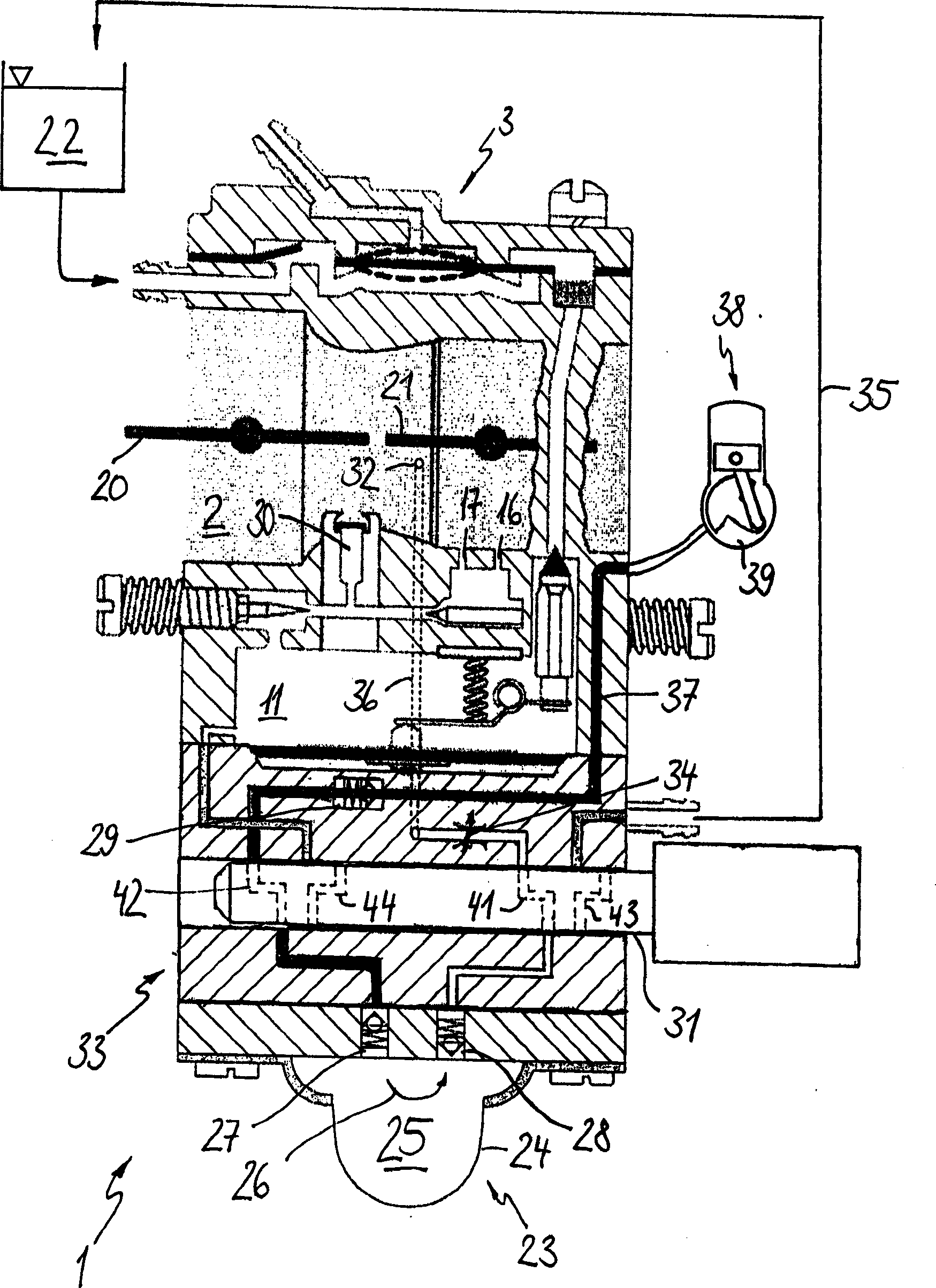

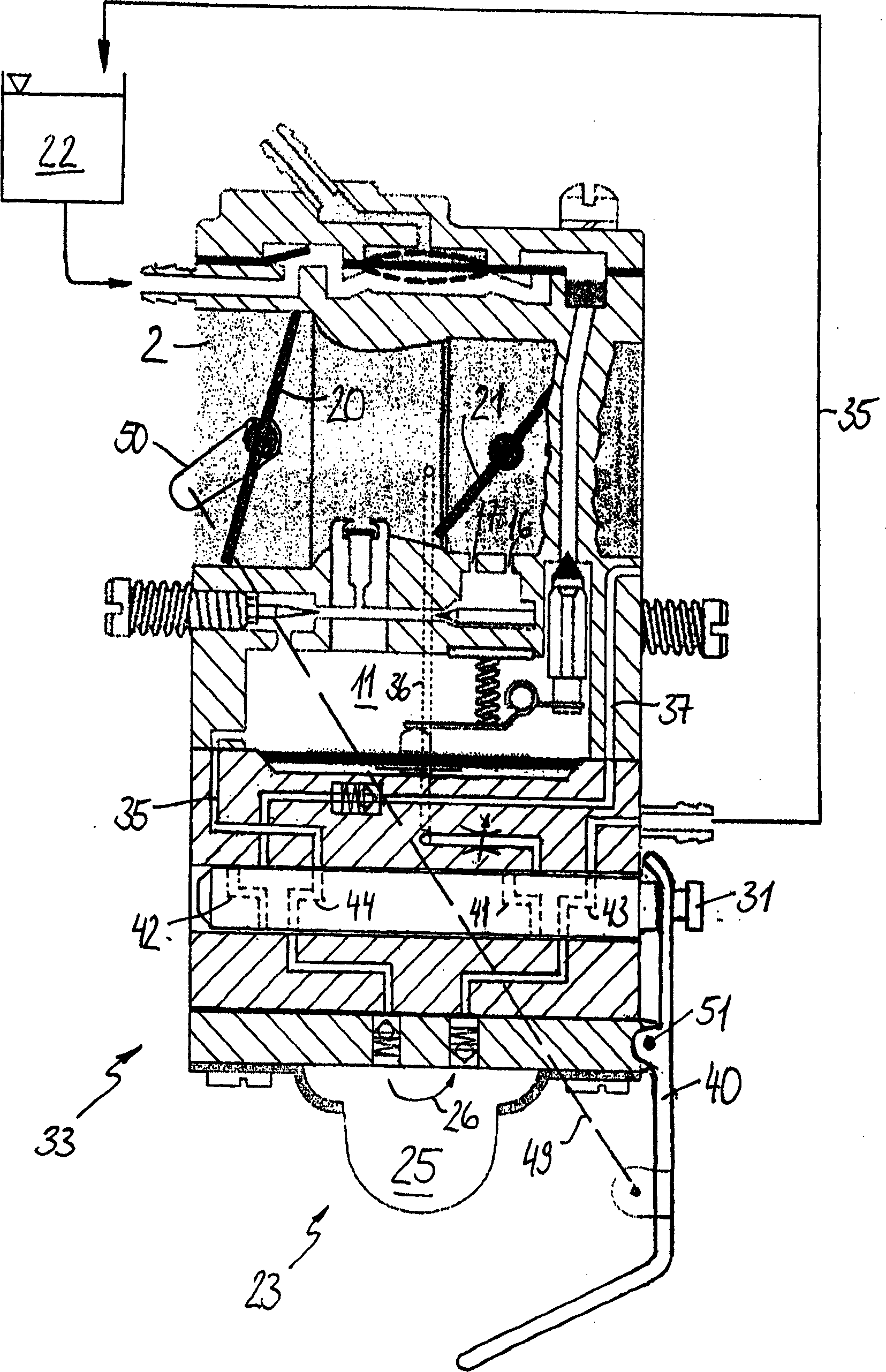

[0017] figure 1 Shown is a carburetor system consisting of a diaphragm carburetor 1 in which a scavenging pump standard unit 33 is integrated. However, the scavenging pump standard assembly 33 can also be formed independently. In the diaphragm carburetor 1 there is an air duct 2 in which is arranged a rotatably mounted choke valve 20 and downstream of the choke valve 20 a throttle valve 21 . Air duct 2 has a Venturi section 45 , in particular in the region between choke valve 20 and throttle valve 21 . In the region of the throttle valve 21 , a primary idle nozzle 16 opens into the air duct 2 , and upstream of the primary idle nozzle 16 a secondary idle nozzle 17 opens into the air duct 2 . When the throttle valve 21 is closed, the primary idle nozzle 16 is located downstream of the throttle valve 21 and the secondary idle nozzle 17 is located upstream of the throttle valve 21 .

[0018] A main nozzle 30 opens into the gas channel 2 in the region of the Venturi section 45 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com