BUCK convertor containing synchronous rectitication drive circuit

A drive circuit and synchronous rectification technology, which is applied in the conversion equipment with intermediate conversion to AC, DC power input is converted to DC power output, and AC power input is converted to DC power output. Only partially adjustable, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

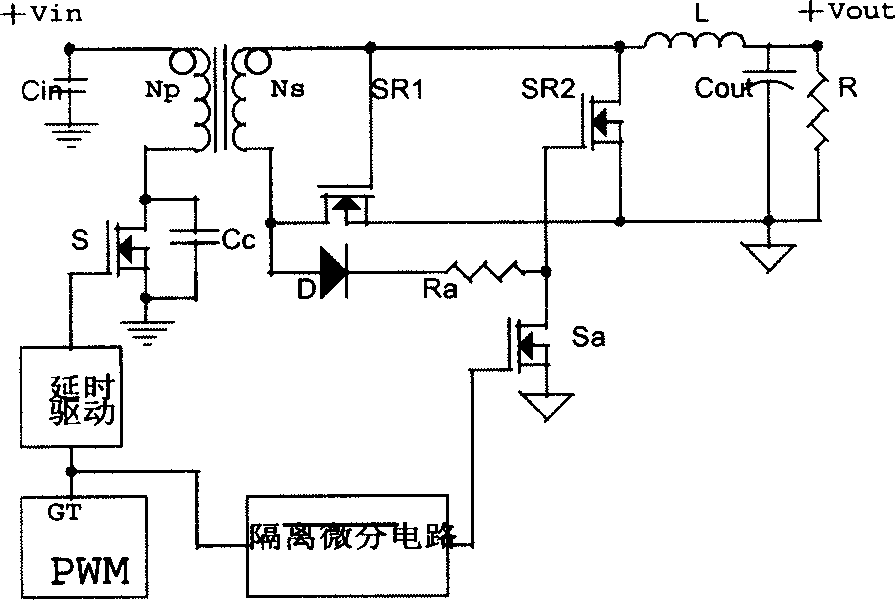

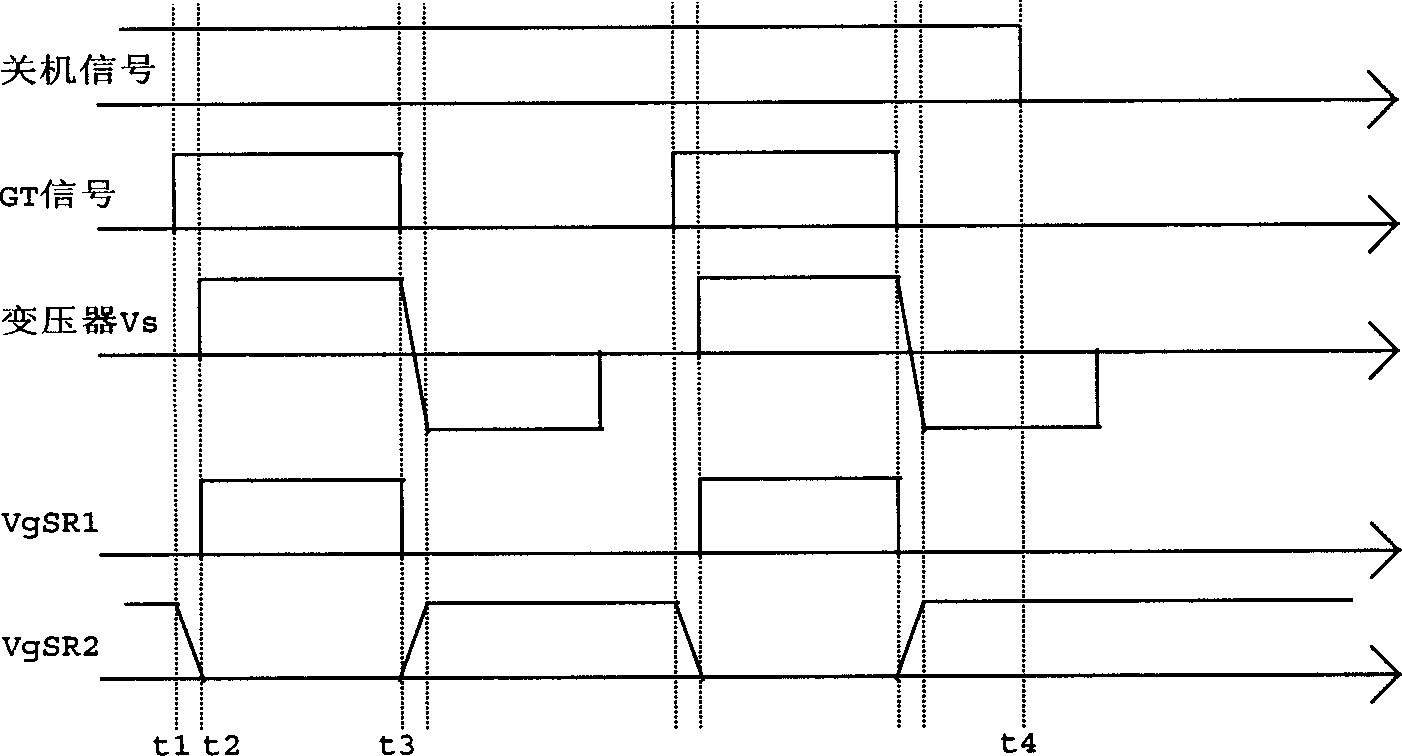

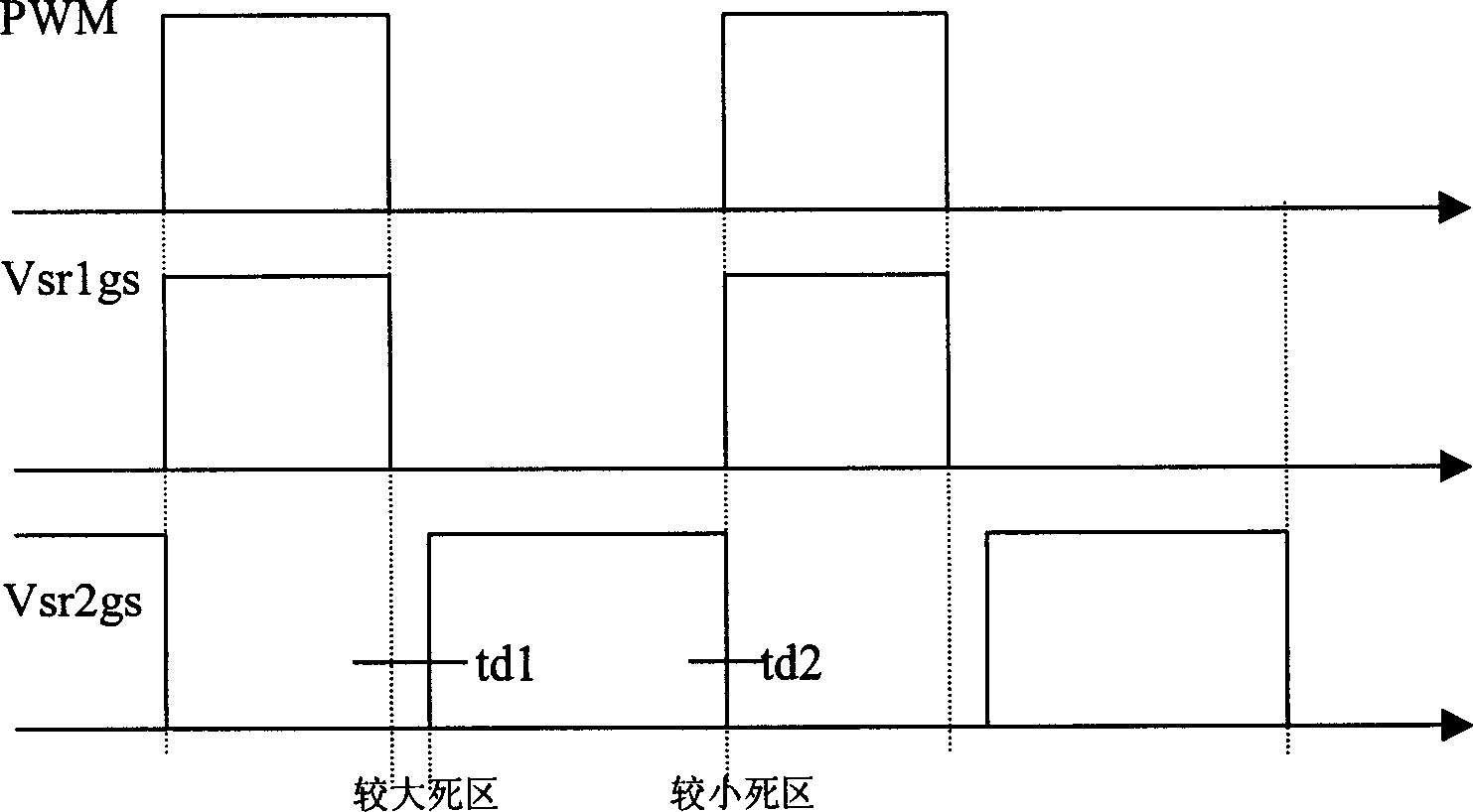

[0044] The drive circuit of the DC-DC converter of the present invention, the main circuit of the converter includes a power MOS tube part, a transformer part, a synchronous rectification part (SR1, SR2), and a filter part, and the drive circuit is composed of an adjustable pulse width Drive pulse signal GT2, an isolated differential circuit, a level comparison and energy conversion circuit MOS transistor Sa, a complementary drive circuit, resistors Ra, Rb, Rc, auxiliary power supply Vcc1 and reference level. The output terminal of the drive pulse signal GT2 with adjustable pulse width is connected to the resistor Ra, the resistor Ra is connected to the input terminal of the isolated differential circuit, and the output terminal of the isolated differential circuit is connected to the level comparison and energy conversion circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com