Bottle with bottom hanging device, forming method and injection mould

A bottle and hanger technology, applied in the fields of bottles and their forming methods and injection molds, can solve the problems of limited depth of concave parts, limited size of hanging pieces, increased cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

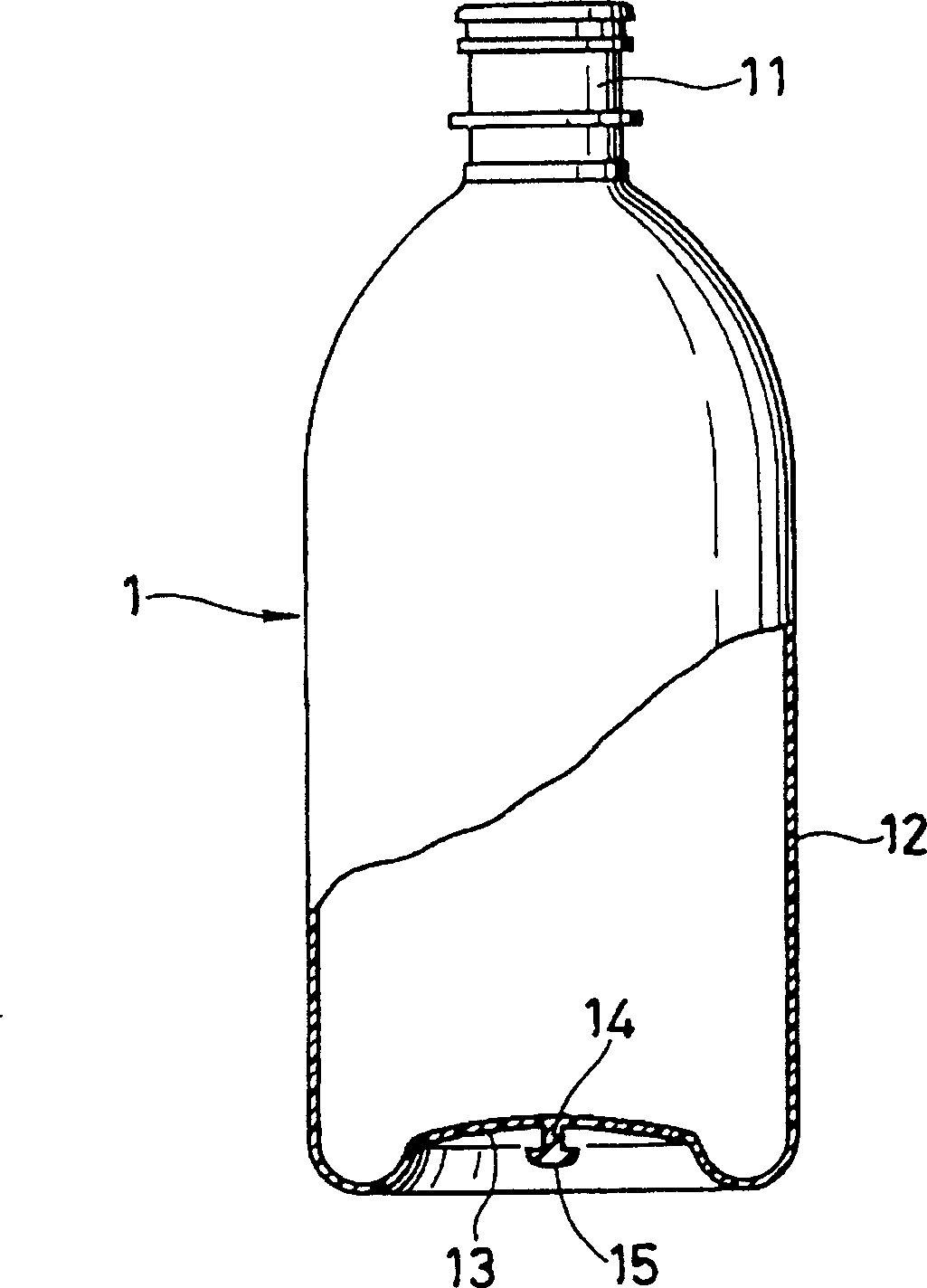

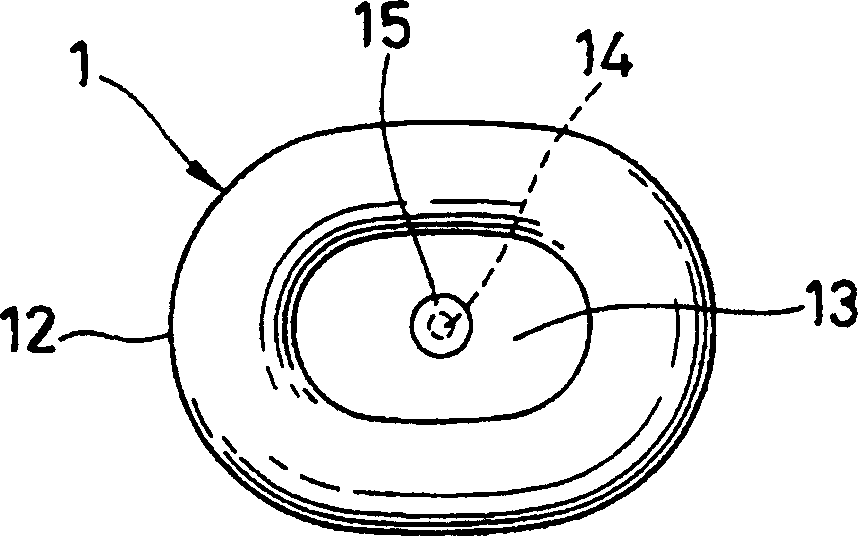

[0016] figure 1 as well as figure 2 It is an infusion bottle 1 made of polypropylene (PP). The bottle body 12 connected to the bottleneck 11 and the bottle bottom 13 concave into the bottle are stretched and blow molded into a thin wall thinner than the bottleneck 11. At the bottom of the bottle The center of 13 integrally forms the suspender of the umbrella-shaped suspension hook that is made up of pillar 14 and flange 15.

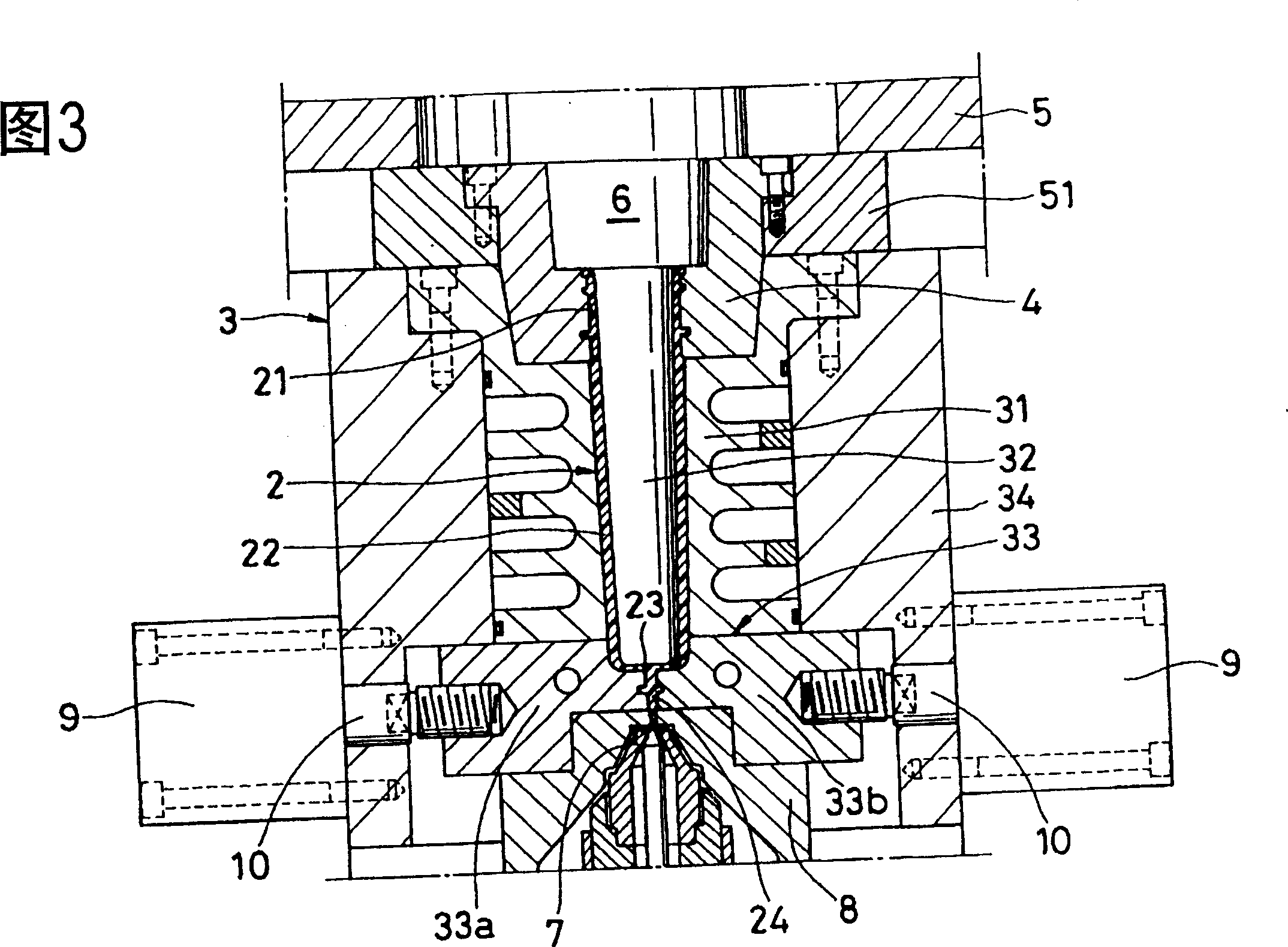

[0017] The bottle 1 with the hanger is formed as follows, that is, the neck 21 and the bottle body 22 and the bottom 23 are integrally injection molded with the injection mold shown in Figure 5 The blow mold 100 shown below stretch-blows the preform 2 into a thin-walled bottle, protruding from the base end portion of the sprue base end 24 provided at the center of the bottom of the preform 2 , and integrally molding around the sprue. The flange 25 becomes the above-mentioned pillar 14 and the flange 15 protruding from the outer bottom surface of the b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap