Semi-prefabricated construction method for prefabricated floorslab and buliding floorslab with wire pipe

A construction method and technology for prefabricated buildings, which are applied in building structures, floor slabs, buildings, etc., can solve the problems of prolonged construction period, chaotic construction site, low work efficiency, etc., so as to shorten the construction period, reduce construction costs and procedures. Simplified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

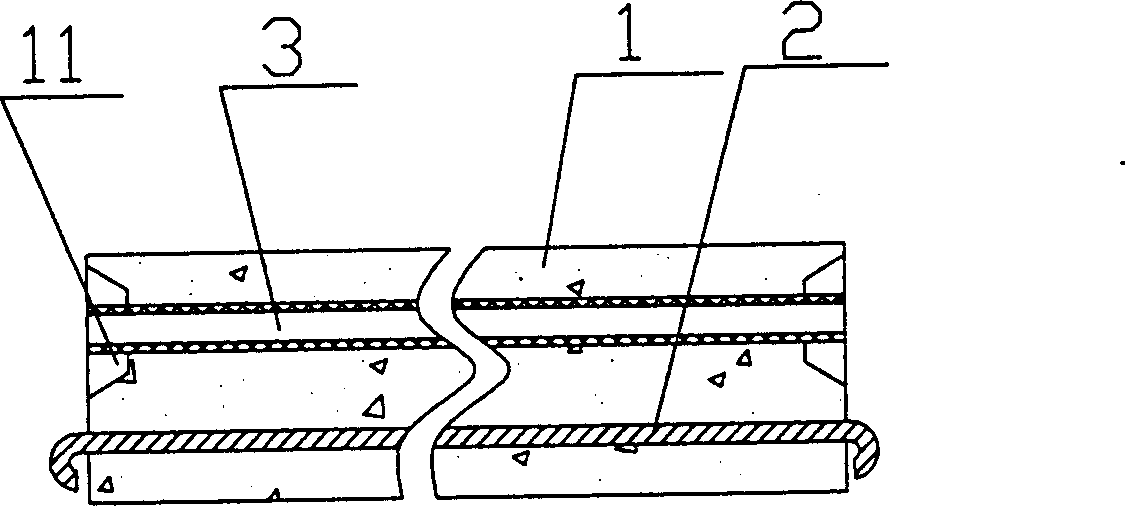

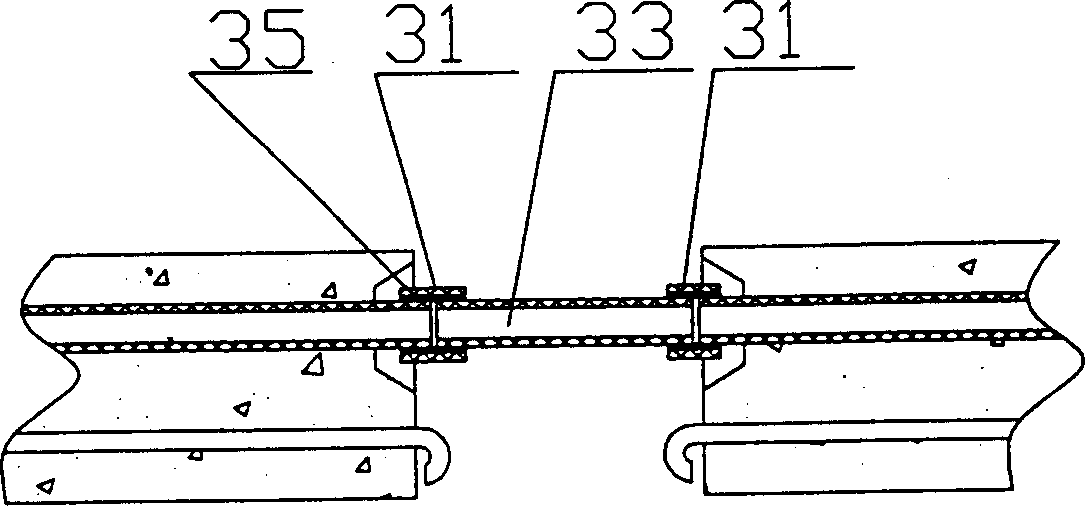

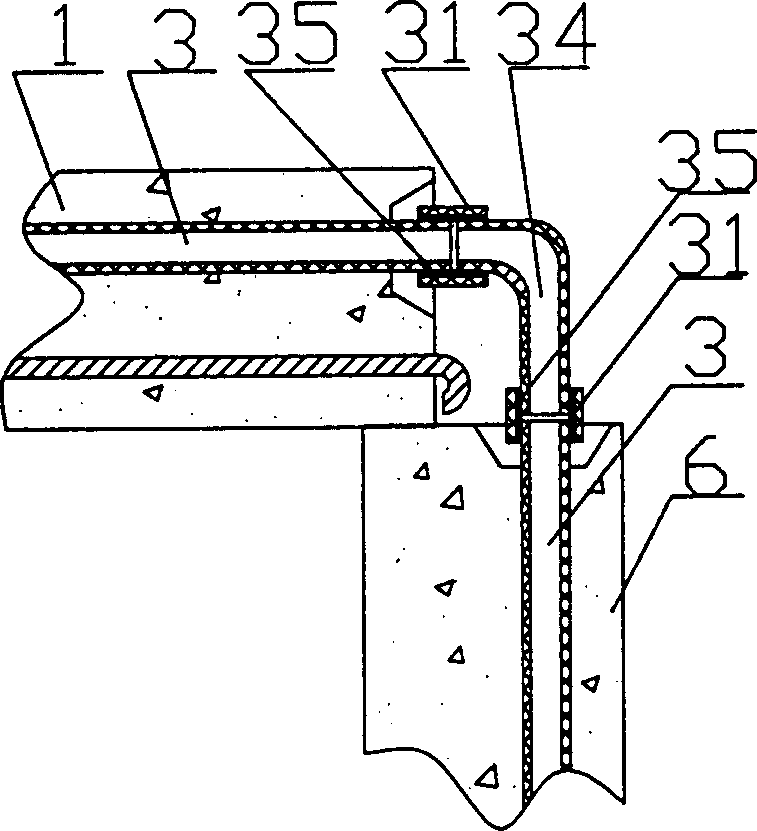

[0026] Depend on figure 1 It can be seen that a prefabricated floor panel with wire pipes includes a floor panel body 1 composed of a steel mesh 2 and a concrete layer poured to cover the steel mesh 2. The interior of the floor panel body 1 is pre-embedded with a cable pipe 3, so that The ends of the line pipes 3 are led into the groove 11 on the edge of the floor panel body 1 or protrude from the upper and lower surfaces of the floor panel body 1 . The connection between the ends of the two line pipes 3 is through barge. In this technical scheme, the process of on-site wire pipe tying after the wire pipe 3 is installed on the prefabricated floor is advanced to the prefabricated part factory, that is, the wire pipe 3 is directly embedded in the prefabricated floor, so that the construction site is fastened. The line pipe 3 process is greatly simplified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com