Liquid crystal display device

A liquid crystal display device, liquid crystal technology, applied in optics, instruments, nonlinear optics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

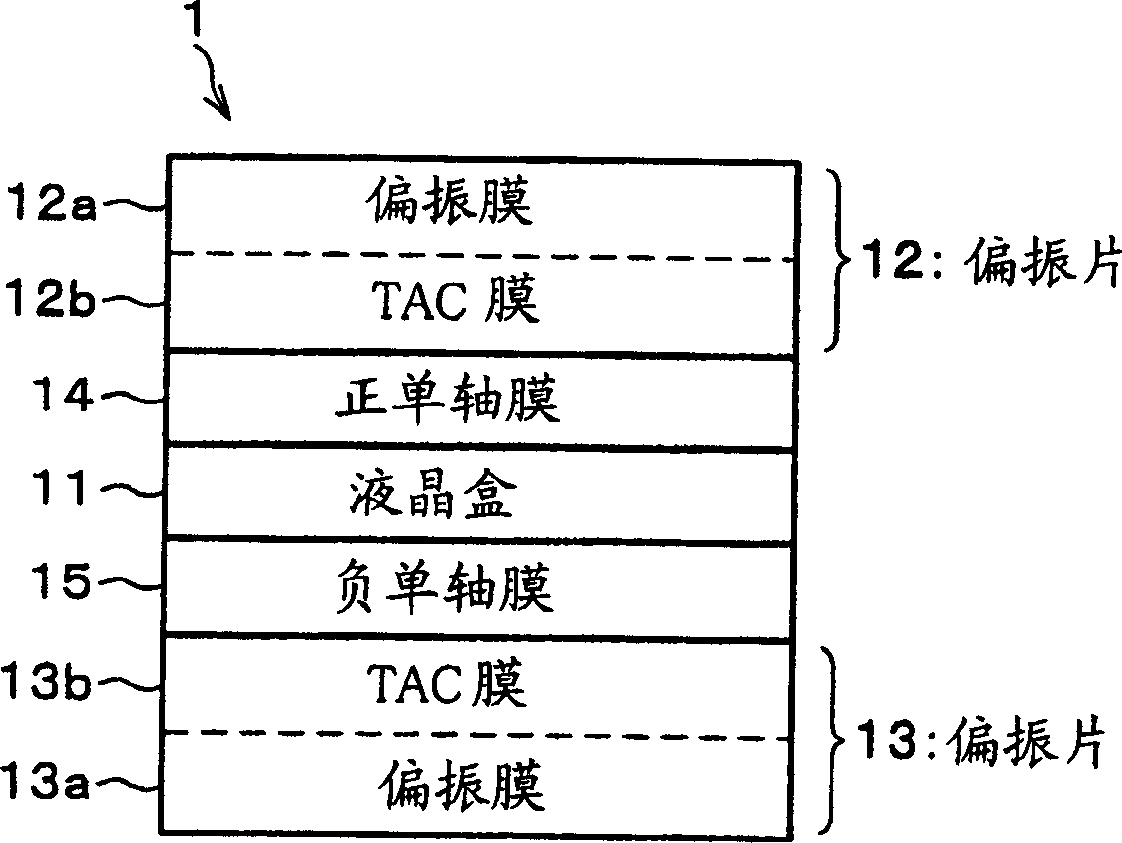

Embodiment 1

[0097] In this embodiment, as the liquid crystal cell 11, liquid crystal cells having a refractive index anisotropy Δn of the liquid crystal layer 11c of 0.08 and a thickness (cell thickness dlc) of 3.0 [micrometer], 4.0 [micrometer], and 5.0 [micrometer] were prepared. , that is, the retardation Rlc (=dlc·Δn) in the thickness direction is respectively 24 0 [nm], 320 [nm] and 400 [nm] of the liquid crystal cell. In addition, TAC films having retardation Rtac in the thickness direction of 0 [nm], 30 [nm], 50 [nm], and 80 [nm] were prepared as the TAC films 12 b and 13 b. In addition, Rp and Rn at which the contrast ratio when viewed from an oblique direction is maximized were obtained for each of the combinations of the liquid crystal cells 11 and the TAC films 12b and 13b. As a result, get Figure 7 The experimental results shown.

[0098] Furthermore, when measuring the contrast, the viewing angle when the liquid crystal display device 1 is actually used, that is, the inclu...

Embodiment 2

[0122] In this example, the same liquid crystal cell 11 and TAC films 12b, 13b as in Example 1 above were prepared, and for each combination of the two, when viewed from the same oblique direction as in Example 1, the Contrast becomes the largest Rp and Rn. From this, got Figure 11 The experimental results shown.

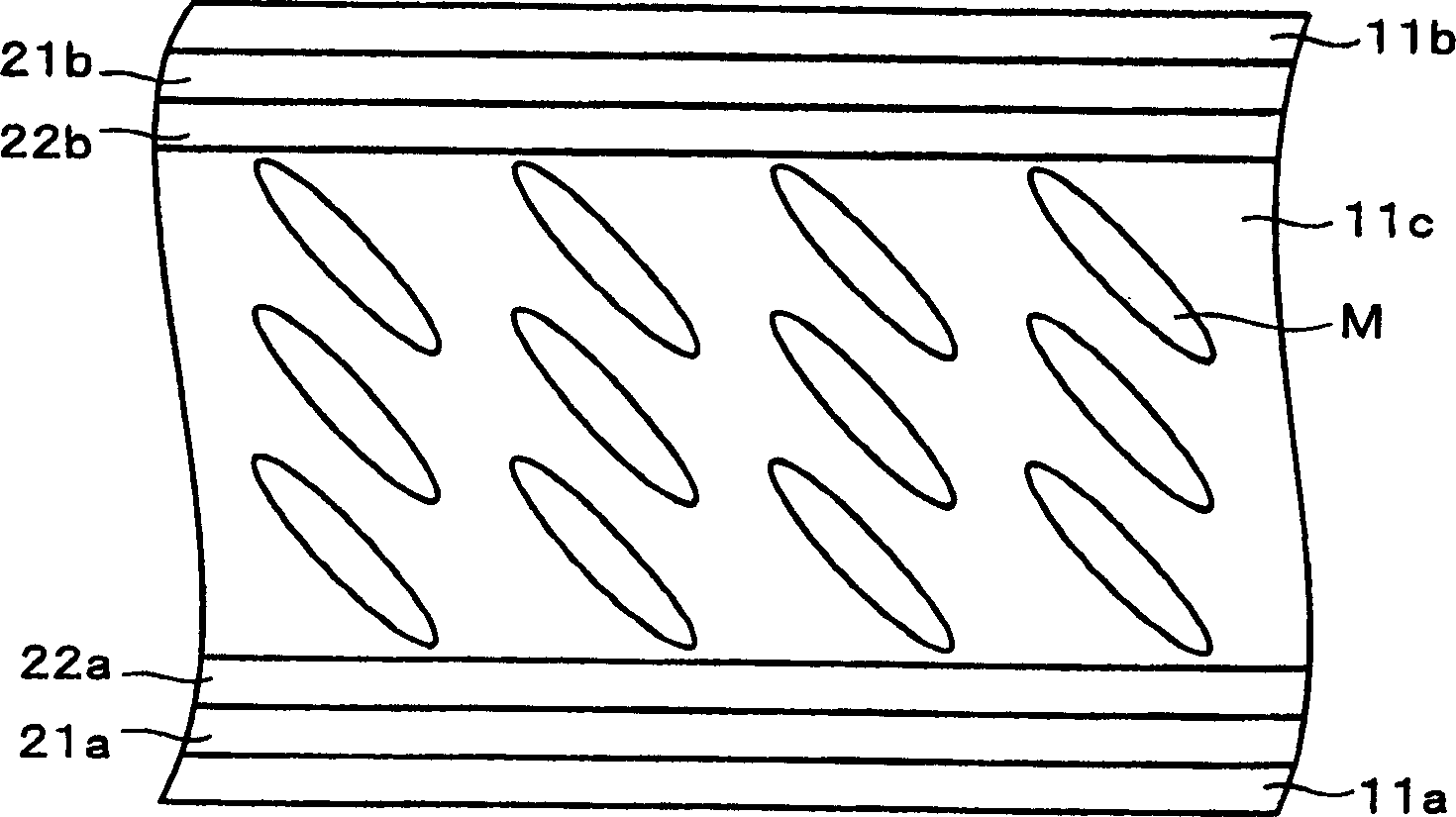

[0123] Thus, if Figure 9 As shown, when the stacking order of the positive uniaxial film 14 is arranged between the negative uniaxial film 15 and the liquid crystal cell 11, and the retardation Rp in the in-plane direction of the positive uniaxial film 14 is the same as the above-mentioned parameter α2, the negative When the retardation Rn in the thickness direction of the uniaxial film 15 is the same as the above-mentioned parameter β2, the liquid crystal display device 1b in which the maximum contrast can be obtained can be confirmed. In addition, from the above experimental results, the above formulas (5) and (6) can be calculated.

[0124] In addition, in ...

Embodiment 3

[0156] In this example, the same liquid crystal cell 11 and TAC films 12b, 13b as in Example 1 above were prepared, and for each combination of the two, when viewed from the same oblique direction as in Example 1, the Contrast becomes the largest Rxy and Rxy. From this, got Figure 15 The experimental results shown.

[0157] Such as Figure 12 As shown, when the lamination sequence of the biaxial film 16 is arranged between the liquid crystal cell 11 and one of the polarizers 12 and 13 (in the case of the illustration, the polarizer 12), and in the plane of the biaxial film 16 When the directional retardation Rxy is the same as the parameter α3 described above, and the retardation Rz in the thickness direction of the biaxial film 16 is the same as the parameter β3 described above, the liquid crystal display device 1c that can obtain the maximum contrast can be confirmed. Also, by approximating the above experimental results with a linear equation, the above equations (9) an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com