Low-harmonic AC motor controller and control method

A technology of AC motor and control method, applied in the direction of AC motor control, DC motor speed/torque control, control system, etc., can solve problems such as interference, achieve the effect of reducing harmonic and electromagnetic wave radiation, and small harmonic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Referring to the accompanying drawings, specific embodiments of the present invention will be described in detail.

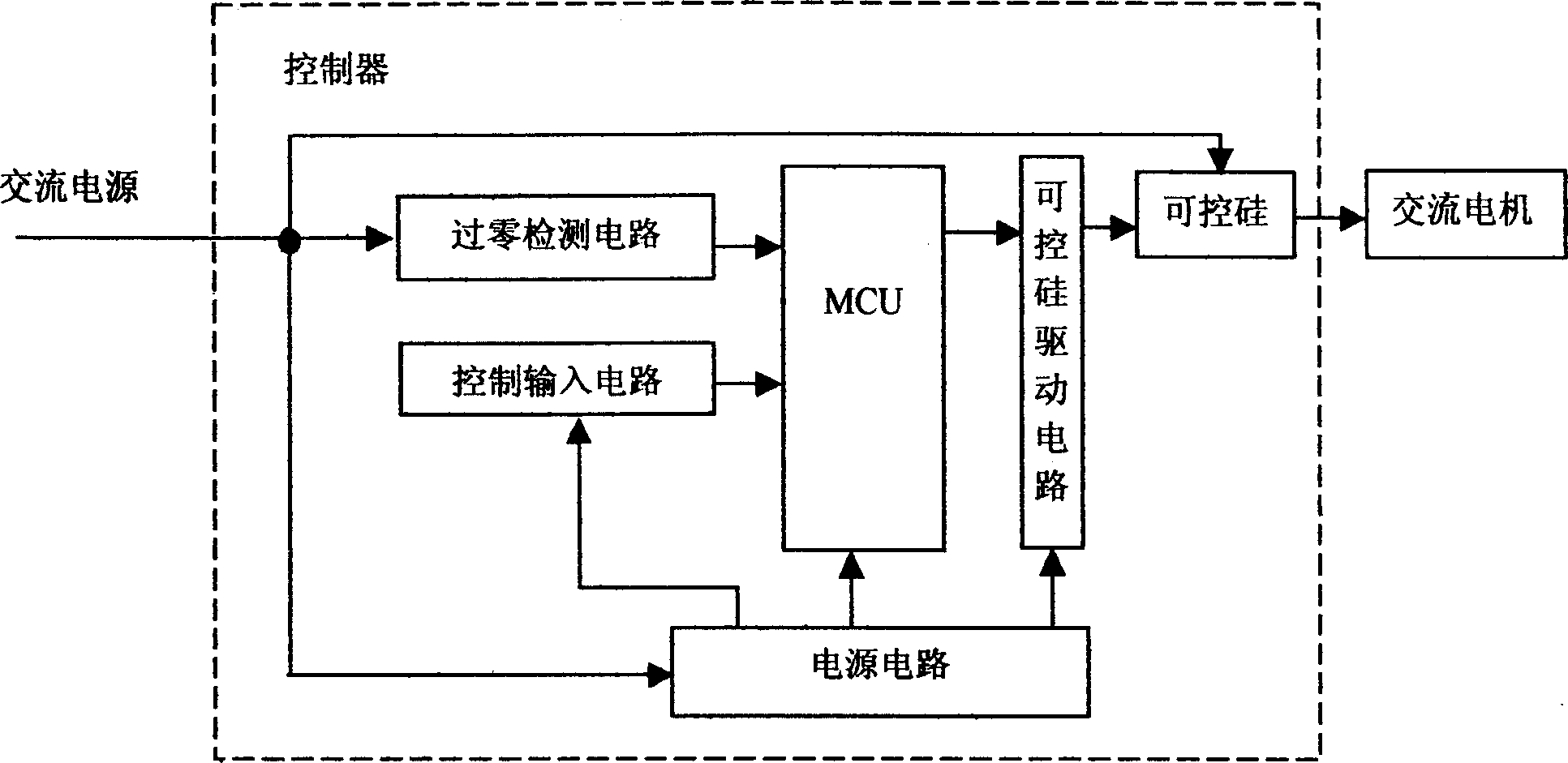

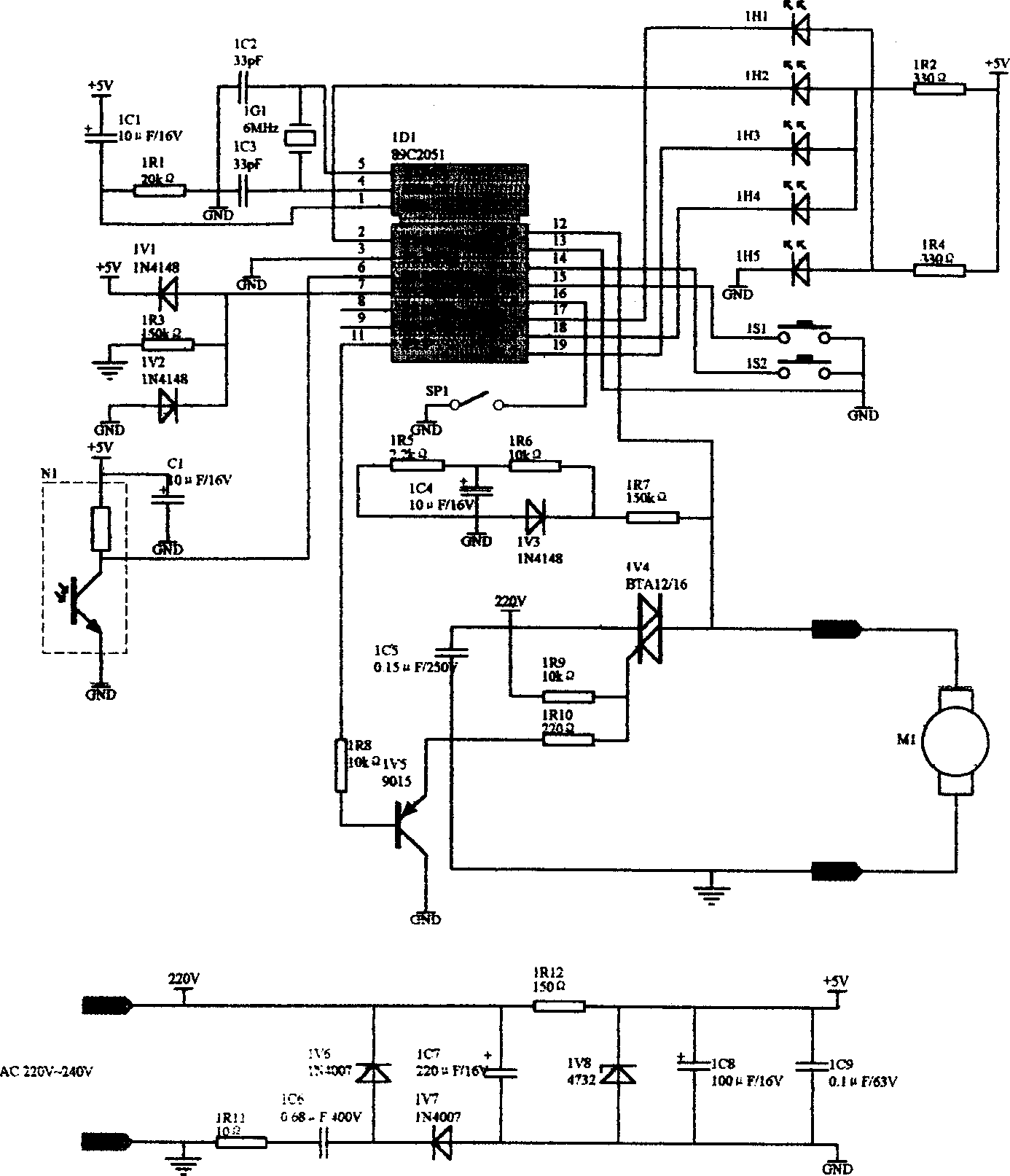

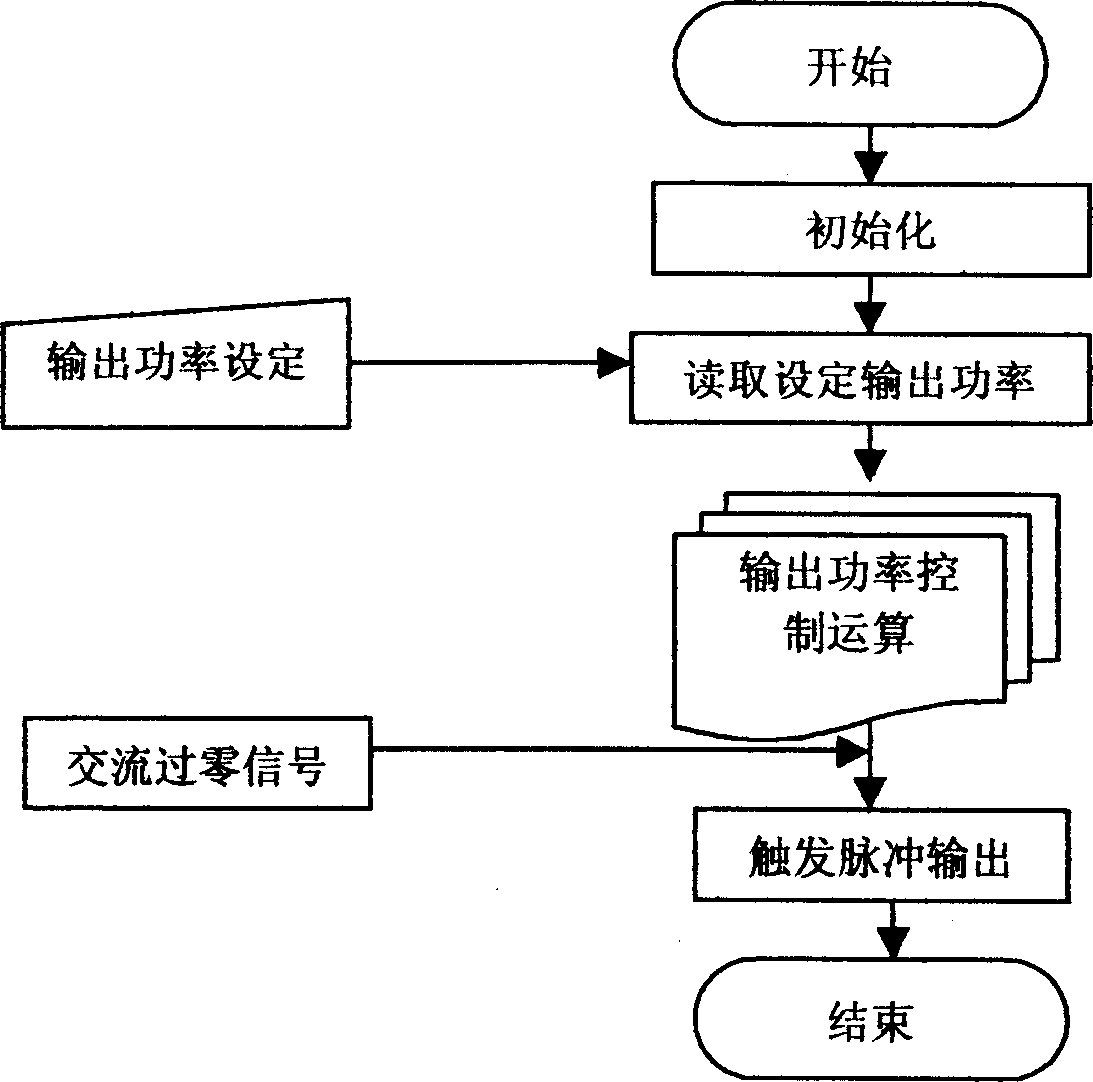

[0035] figure 1 The electrical principle block diagram of the present invention is given, the low-harmonic AC motor controller is powered by an AC power supply, and a DC power of +5V is output through the power supply circuit to provide a DC working voltage for the controller. The zero-crossing detection circuit and the control input circuit are respectively It is connected with the corresponding input port of the single-chip microprocessor MCU, and the thyristor drive circuit and the bidirectional thyristor are connected in series with an output port of the MCU in turn. Among them, the zero-crossing detection circuit converts the AC sine wave into a square wave signal and inputs it to the external interrupt port of the MCU. When the AC voltage crosses zero, the MCU is interrupted; the control input circuit transmits the received motor output power setti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com