Bituminous binder road-surface mechanized construction process

A technology of asphalt mixture and construction technology, which is applied in the direction of roads, roads, road repairs, etc., can solve problems such as temperature material segregation, achieve the effects of prolonging life, improving utilization rate, and saving road maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

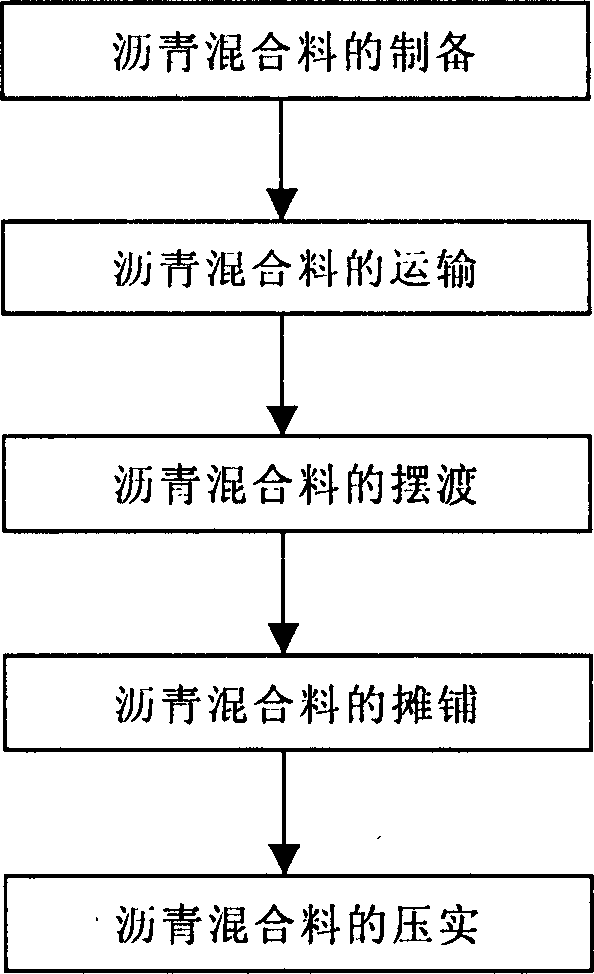

[0013] Referring to accompanying drawing, the technical scheme step that the present invention adopts is as follows:

[0014] (1), preparation of asphalt mixture; (2), transportation of asphalt mixture; (3), ferrying of asphalt mixture; (4), paving of asphalt mixture; (5), pressing of asphalt mixture Reality.

[0015] After the mixing device prepares the material and asphalt into a qualified asphalt mixture, it is loaded on a dump truck, and the dump truck unloads the asphalt mixture into the hopper of the asphalt mixture ferry vehicle. The basic working principle of the ferry vehicle is: A hopper, a feeding scraper system, a silo and a secondary discharging scraper system are arranged on the self-propelled chassis. The dump truck pours the asphalt mixture into the hopper, and the asphalt mixture is poured by the feeding scraper system. Input into the silo, the asphalt mixture is fully stirred in the silo of the asphalt mixture ferry vehicle, and reaches a uniform level, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com