Operation method of two-stroke engine fitted with mixed-gas sunction device

An engine and two-stroke technology, which is applied to combustion engines, machines/engines, mechanical equipment, etc., can solve the problem of increasing the amount of lubricating oil added, and achieve good heat transfer and improved heat conduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

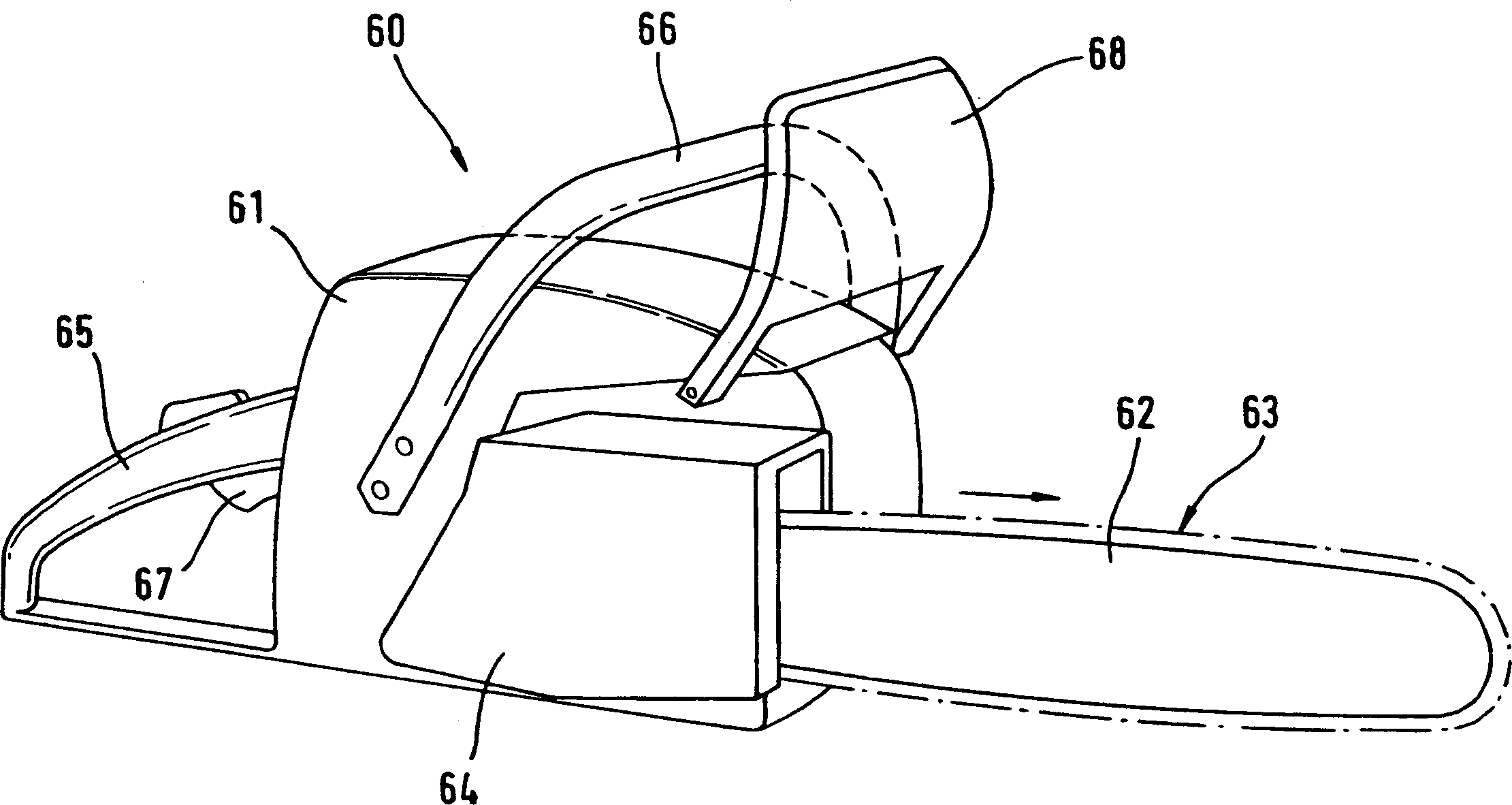

[0021] figure 1 The portable hand-held implement shown in is an electric chainsaw 60 with an internal combustion engine housed in its housing 61, in figure 2 and 6 The internal combustion engine is schematically depicted in . The internal combustion engine drives a tool, in the case of the electric chain saw shown, which is a saw chain 63 that loops on a guide rail 62 . The guide rail is clipped to the housing 61 of the internal combustion engine by means of a sprocket housing 64 . In order to carry and manipulate this implement, a rear handle 65 and an upper handle 66 are provided. A joystick 67 for operating the internal combustion engine is assigned to the rear handle 65 ; a hand guard 68 is arranged in front of the upper, front handle 66 .

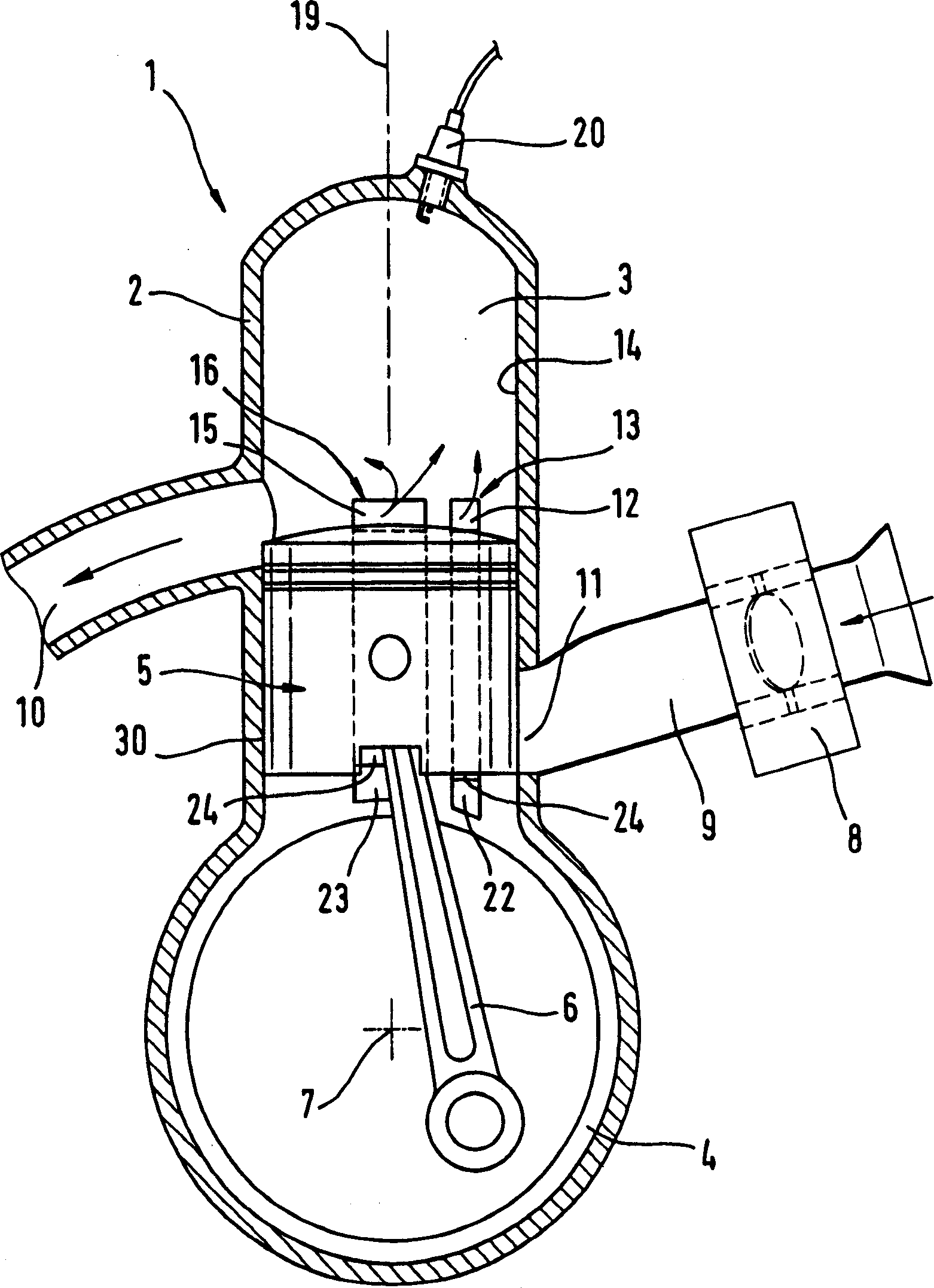

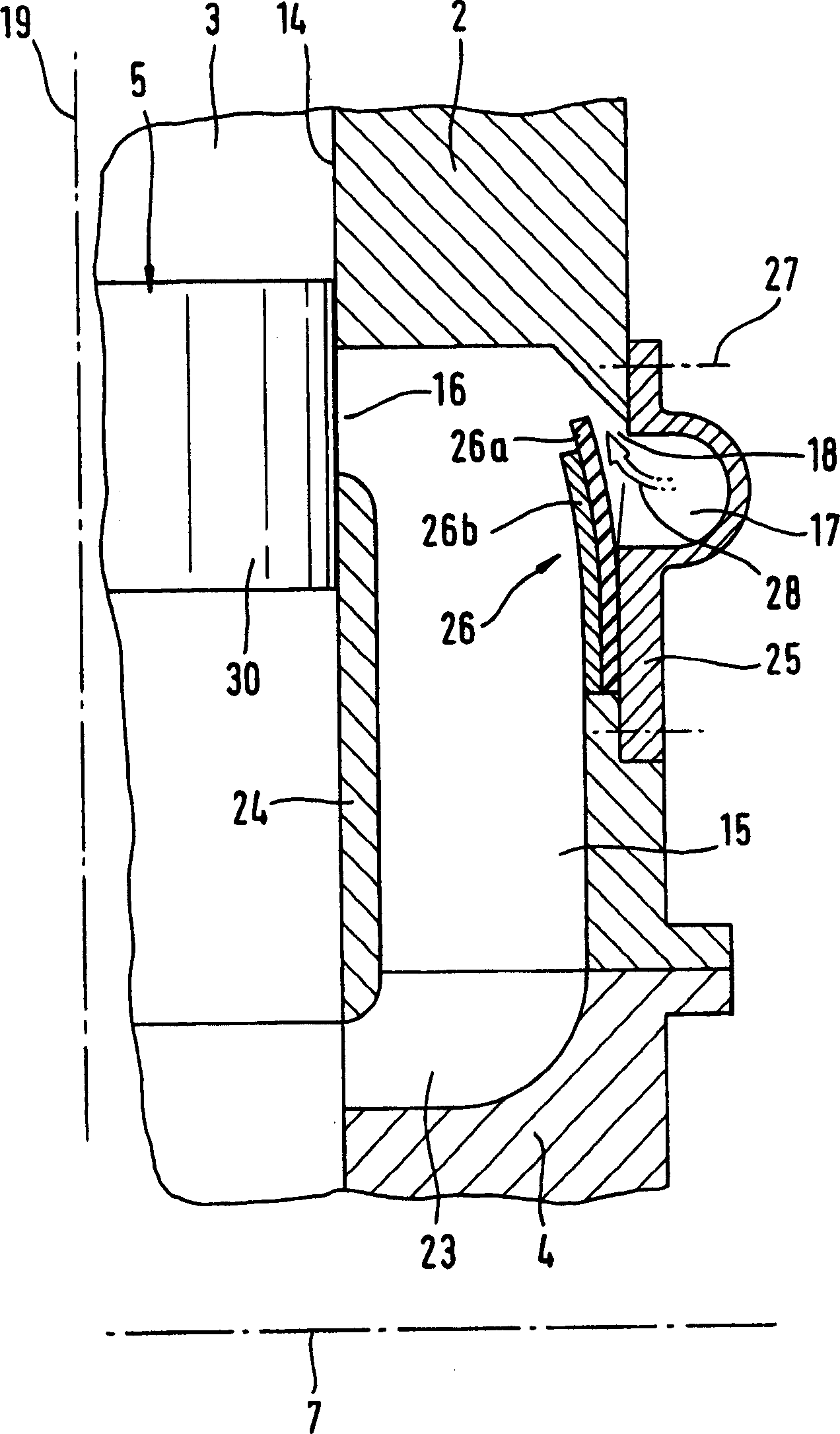

[0022] figure 2 The internal combustion engine 1 schematically depicted in is a two-stroke engine with a scavenging device. It basically consists of a cylinder 2 and a crankcase 4 arranged on the foot of the cylinder 2 . A com...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap