Life managment method for high-temperature gas turbine part and computer programme for realizing same

A technology for high temperature components and gas turbines, applied in gas turbine installations, engine components, machines/engines, etc., to solve problems such as unpredictable cracks and crack growth rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

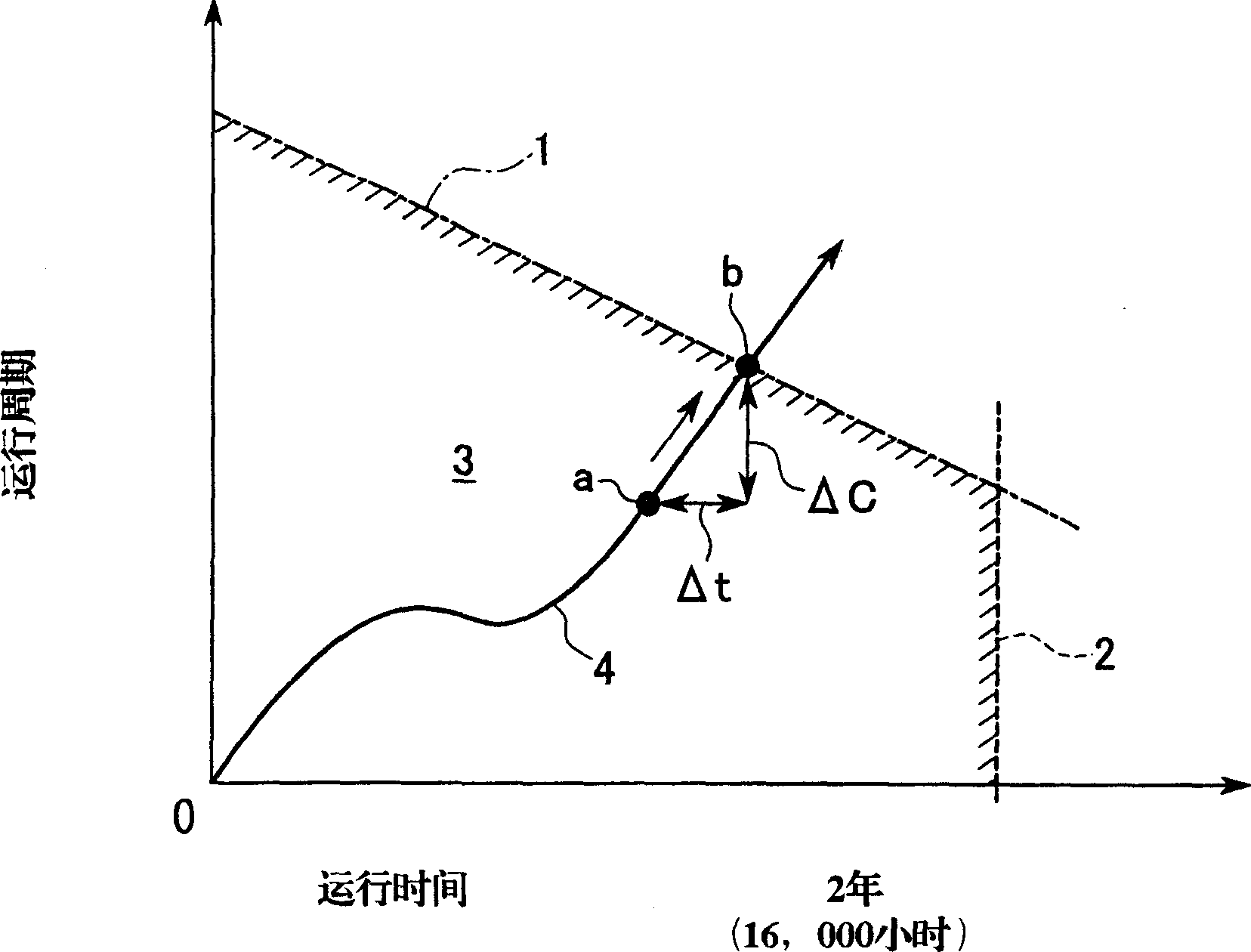

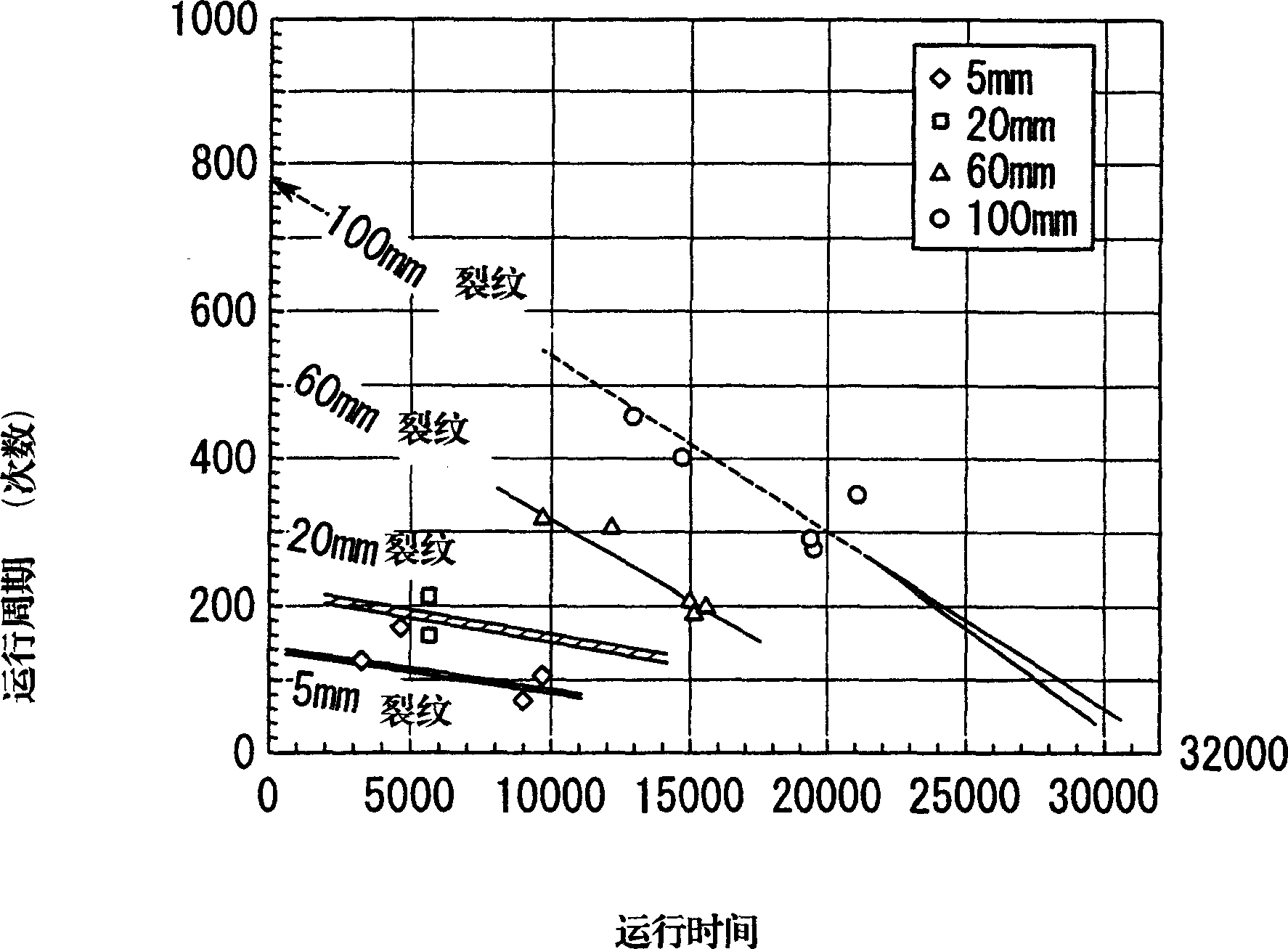

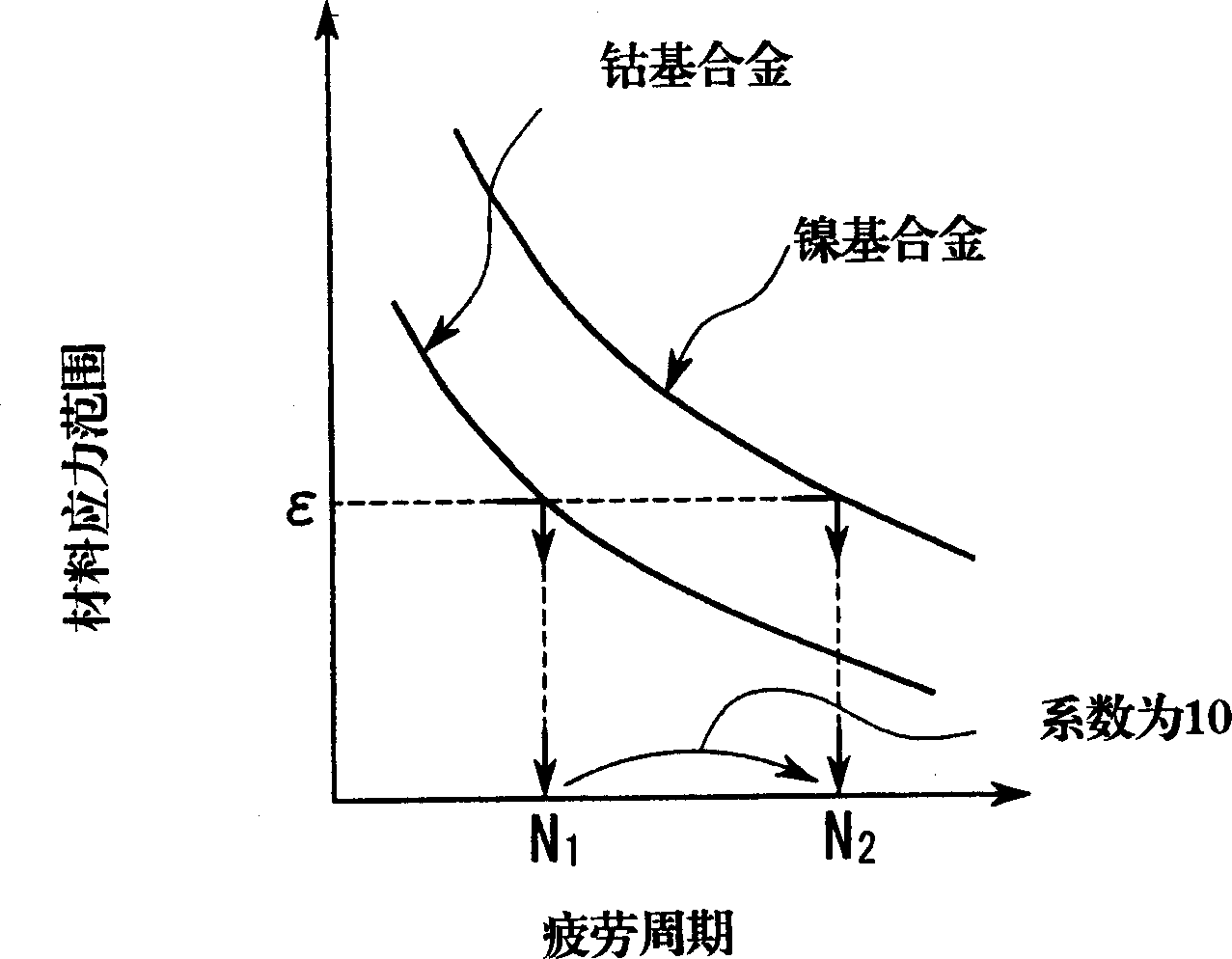

[0019] An embodiment of the method of the present invention for managing the life of high temperature components of a gas turbine and its implementation by a computer program will now be described with reference to the accompanying drawings. It should be understood that this description does not limit the invention in any way.

[0020] Note that the term "high temperature component" in the present invention refers specifically to the combined parts of the gas turbine exposed to high temperature environments, such as turbine rotating blades, turbine stationary blades, and combustor components. In addition, the term "operating cycle" in the present invention refers to the sum of the number of starts and the number of trips (that is, sudden engine stop) for operating the gas turbine. The more engine starts and trips, the higher the fatigue levels in the hot parts, even for the same run time as a gas turbine with fewer trips. In other words, a larger portion of the component's li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com