Automatic colour steel band coating line production process and apparatus thereof

A production process and coating line technology, which can be applied to devices for coating liquids on surfaces, coatings, pretreatment surfaces, etc. The effect of increased efficiency, reduced production costs, and compact process routes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with embodiment and accompanying drawing thereof, further explain:

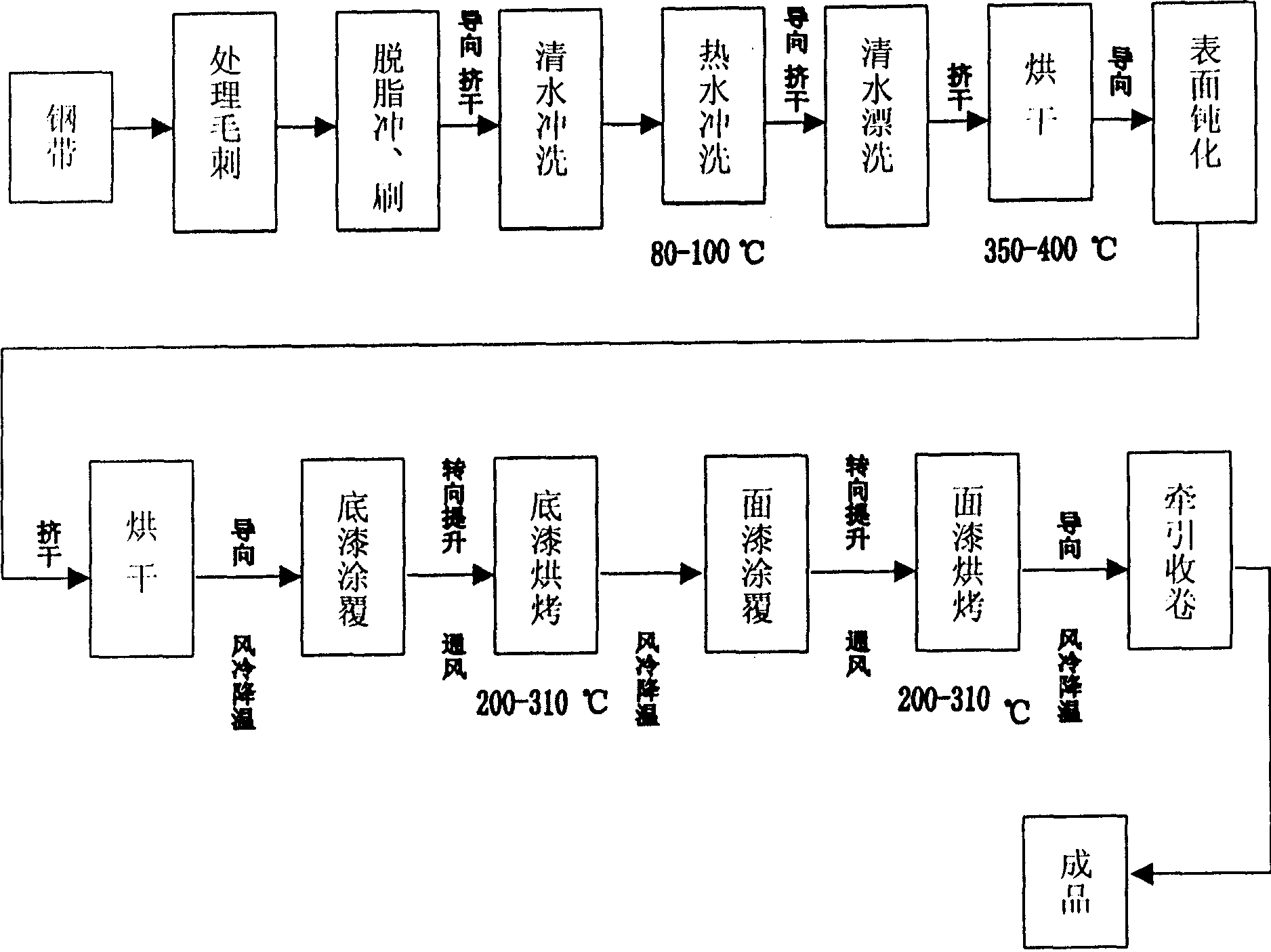

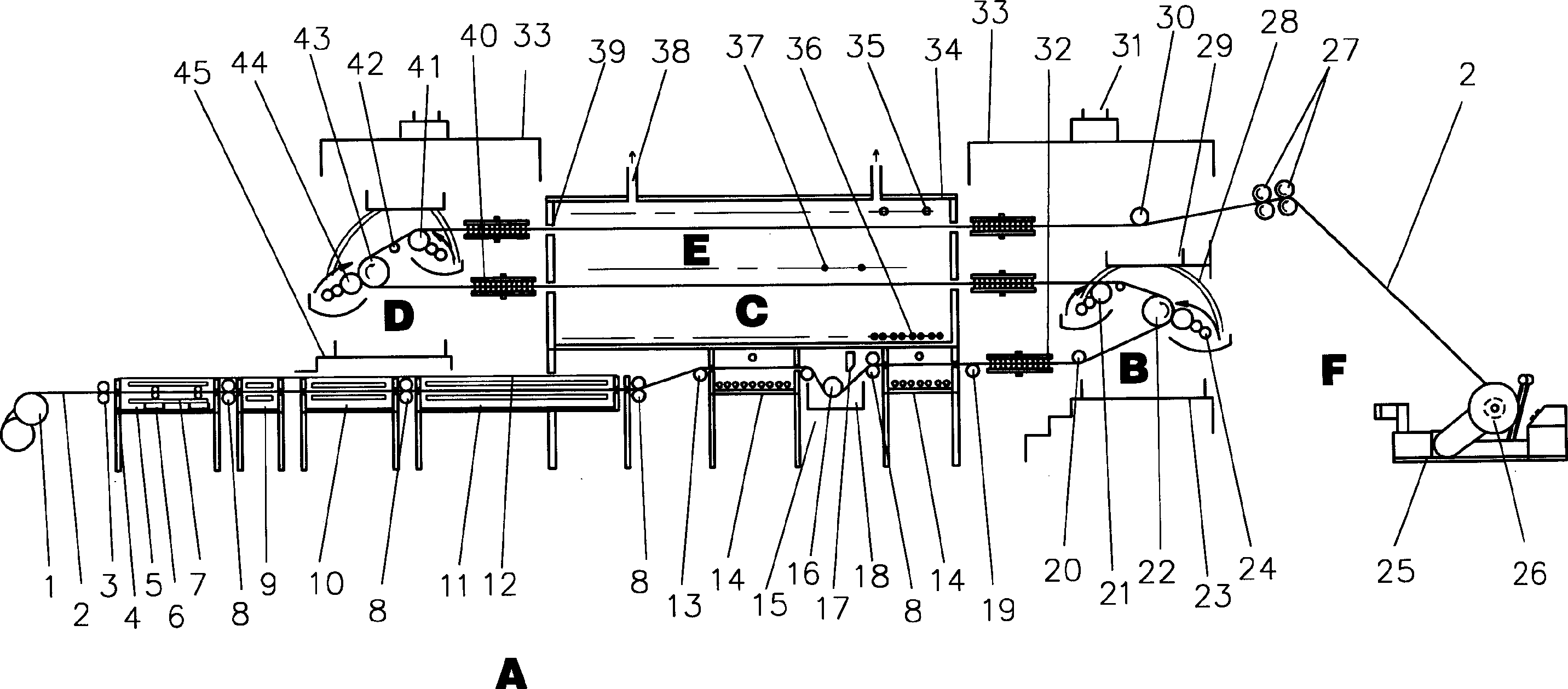

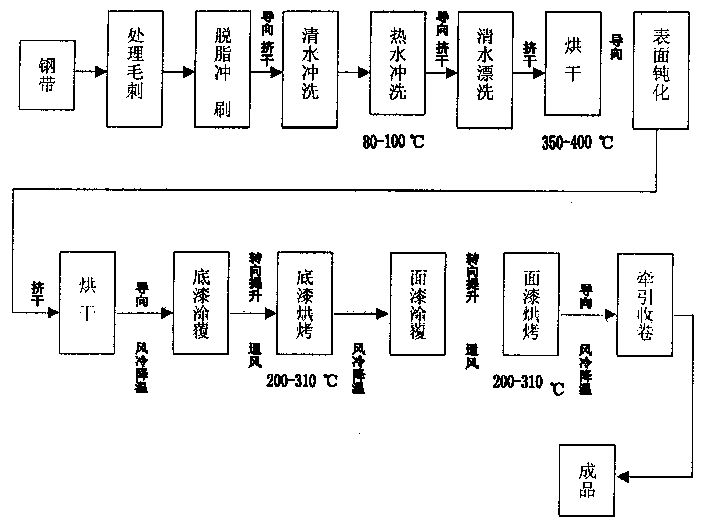

[0031] See attached picture. figure 1 The main process steps and conditions of the embodiment are listed in the block diagram. The production process of the color steel strip automatic coating line of the present invention, its process flow includes the pretreatment process of the steel strip, the primer coating process, the primer baking process, the top paint coating process, the top paint baking process and The traction and winding process sections, the pre-treatment process section is mainly composed of degreasing spray washing, water rinsing, drying, passivation and re-drying process. According to the characteristics of the equipment not moving and the workpiece moving, the following improvements are highlighted: In the treatment process section, two-stage hot water spray washing and three-stage clear water spray washing processes are added, which improves the surface cleanli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com