Variable acoustic pressurizing dual blast heat exchanger

A heat exchanger and shock wave technology, applied in the field of heat exchange, can solve the problems of insignificant energy saving effect, high operating cost, influence of pressurization effect, etc., and achieve the effect of reducing building area, reducing noise pollution and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

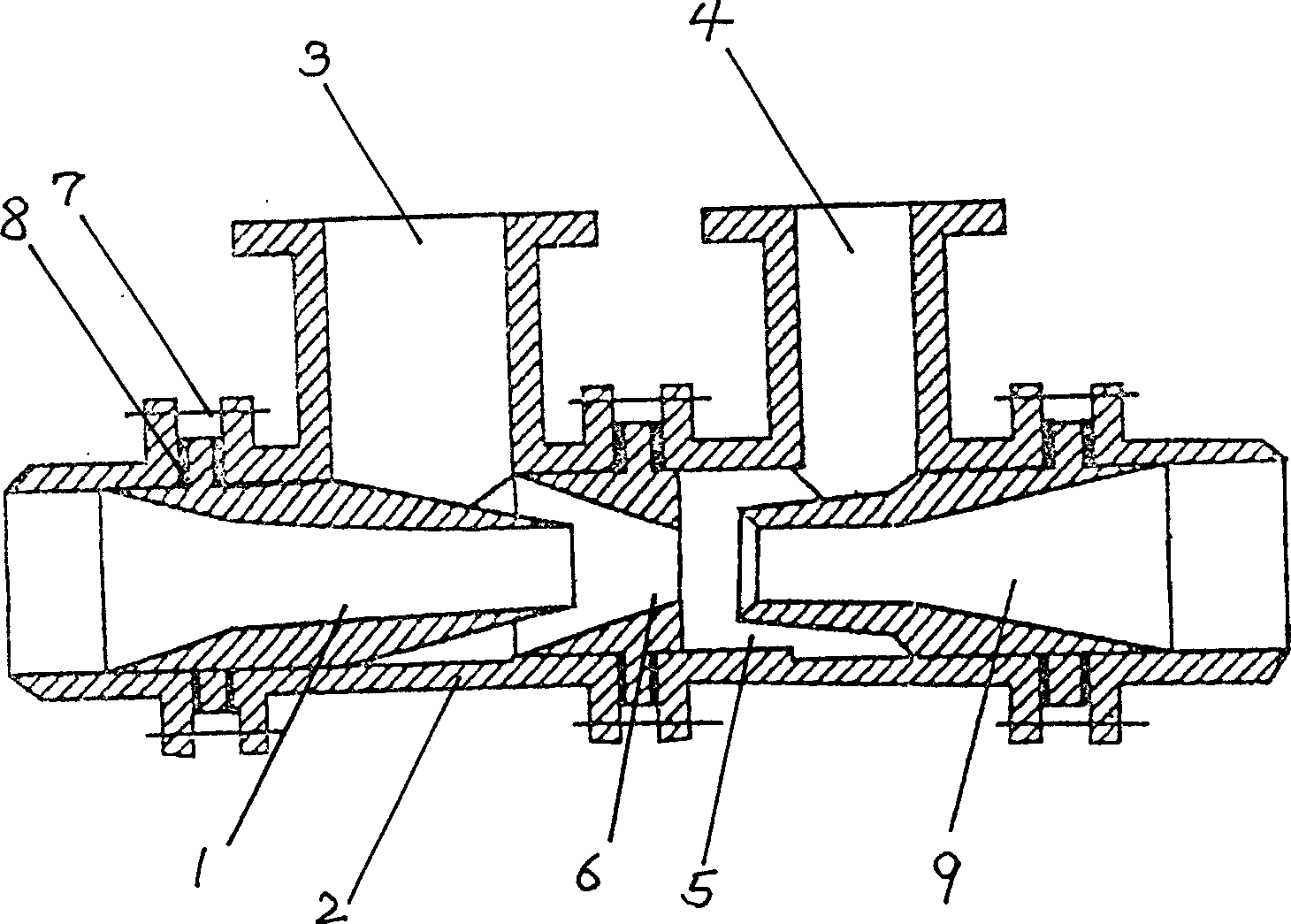

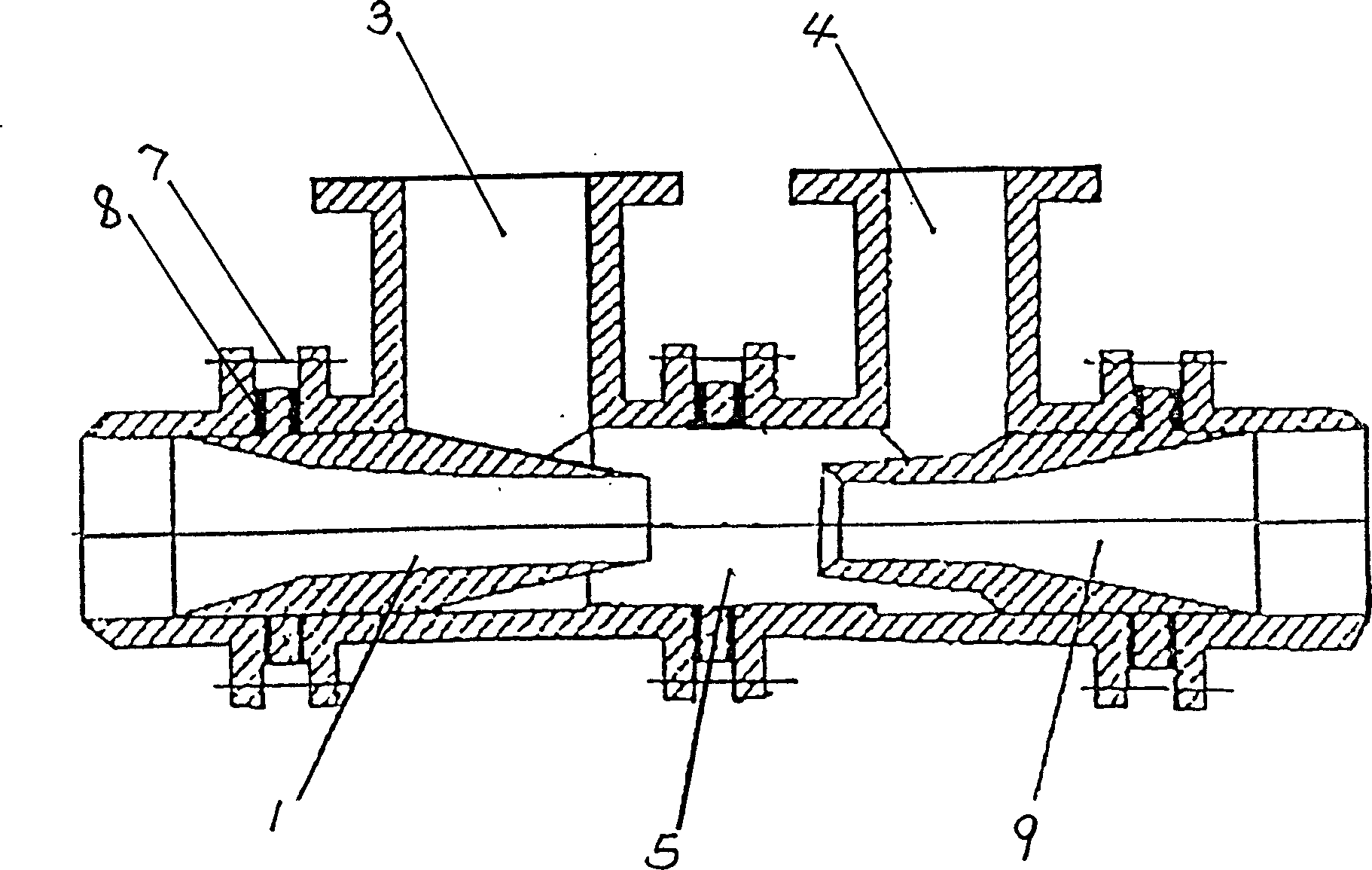

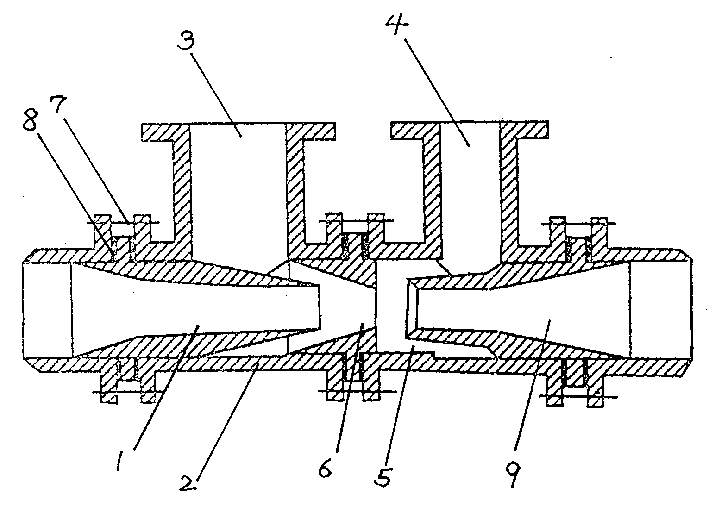

[0015] In conjunction with accompanying drawing, provide embodiment of the present invention as follows:

[0016] like figure 1 As shown, this embodiment is mainly composed of a steam injection pipe 1, a pipe body 2, a mixing chamber 5, a pressurized mixing pipe 6 and a diffuser pipe 9, and the pipe body 2 is provided with an inlet, an outlet, a water inlet 3 and an auxiliary water inlet 4. It can be formed after two tee pipes are fixedly connected through the flange 7. Between the water inlet 3 and the auxiliary water inlet 4 in the pipe body 2, a pressurized mixing pipe 6 and a mixing chamber 5 are arranged. The steam spray pipe 1 communicates, the small-diameter end communicates with one end of the mixing chamber 5 , and the other end of the mixing chamber 5 communicates with the auxiliary water inlet 4 and the diffuser pipe 9 . The steam nozzle 1 adopts a Venturi tube, which is fixedly connected to the inlet end of the pipe body 2 through the flange 7. The diameter of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com