Current sensor and overload current protective device comprising the same

A current sensor and current technology, applied in the direction of measuring current/voltage, voltage/current isolation, instruments, etc., can solve the problems of increasing system volume, large cost, and changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

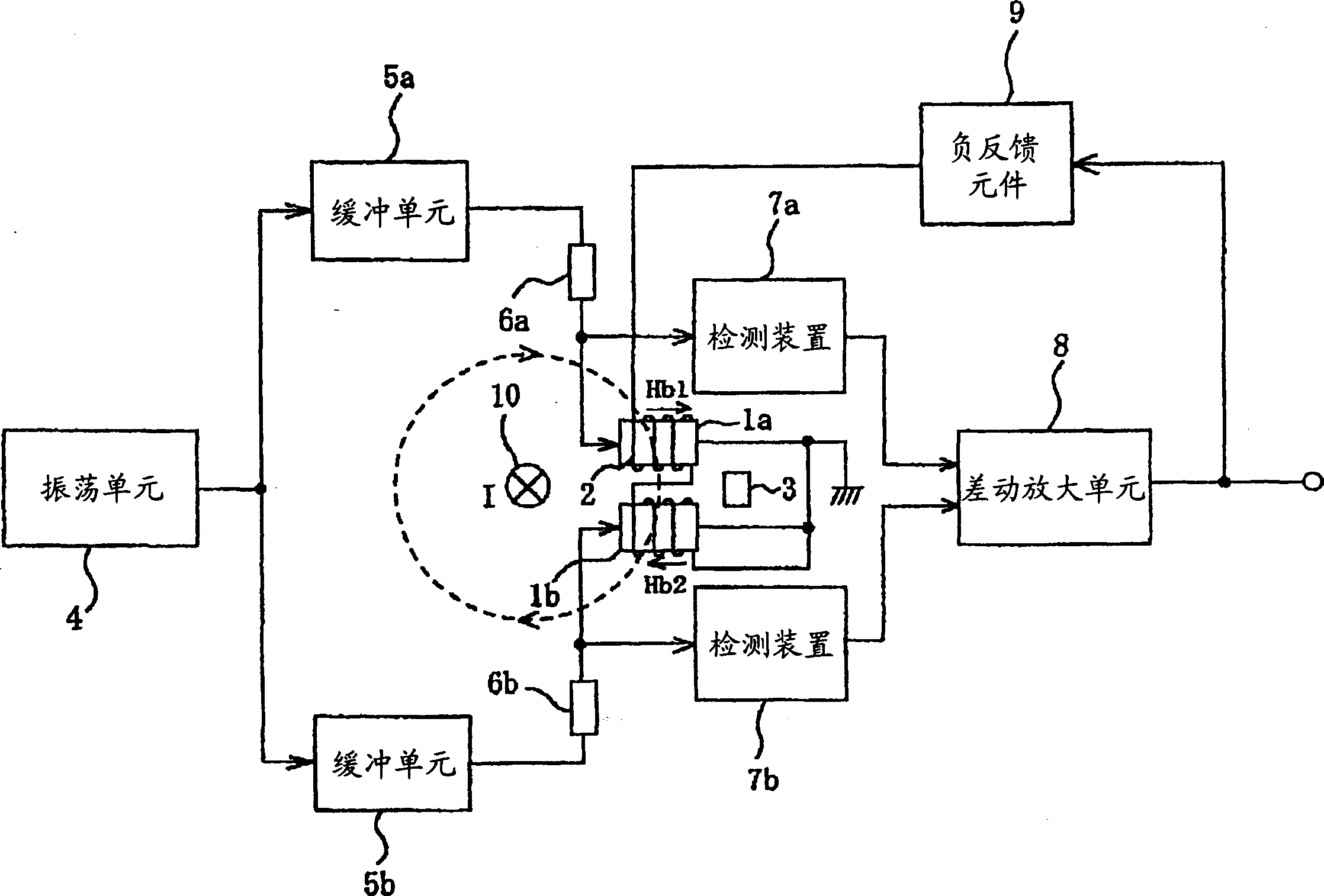

[0039] figure 1 The structure of the first embodiment of the present invention is shown.

[0040] exist figure 1 Among them, the magneto-impedance elements (also referred to simply as MI elements) 1a and 1b can be wire type or film type. Compensation coil 2 applies negative feedback to MI elements 1a and 1b. The magnet 3 applies a DC bias to the MI elements 1a and 1b. The oscillation unit 4 applies DC current to the MI elements 1a and 1b. The buffer units 5 a and 5 b are inserted according to the current level output by the oscillator 4 . Reference numerals 6a and 6b denote resistors. The detection means 7a and 7b detect the variation of the alternating current as a function of the external magnetic field applied to the MI elements 1a and 1b. The differential amplification unit 8 amplifies the output difference of the detection unit. Negative feedback element 9 supplies current to compensation coil 2 according to the output of differential amplification unit 8 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com